Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21 results about "Printing press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A printing press is a mechanical device for applying pressure to an inked surface resting upon a print medium (such as paper or cloth), thereby transferring the ink. It marked a dramatic improvement on earlier printing methods in which the cloth, paper or other medium was brushed or rubbed repeatedly to achieve the transfer of ink, and accelerated the process. Typically used for texts, the invention and global spread of the printing press was one of the most influential events in the second millennium.

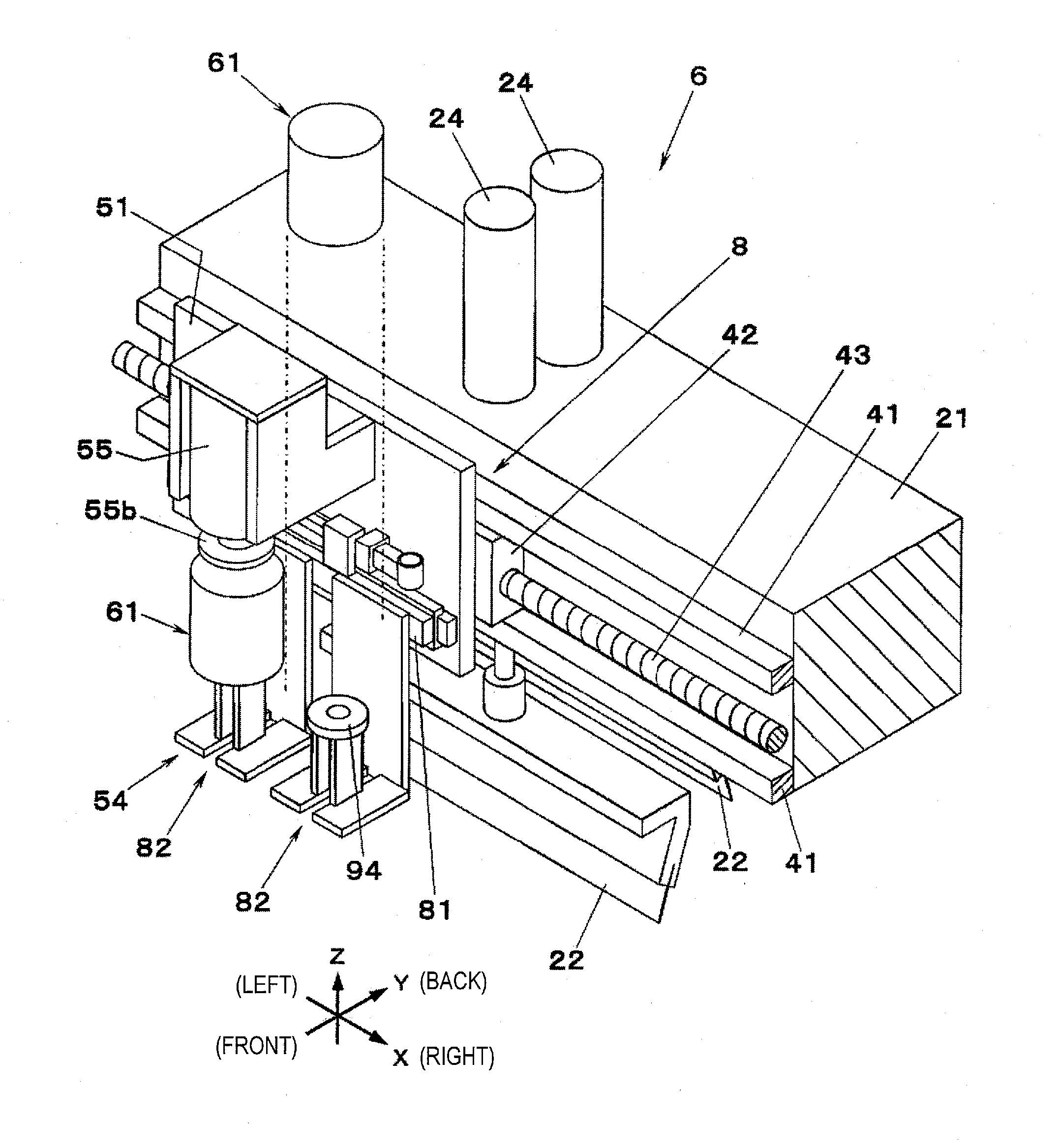

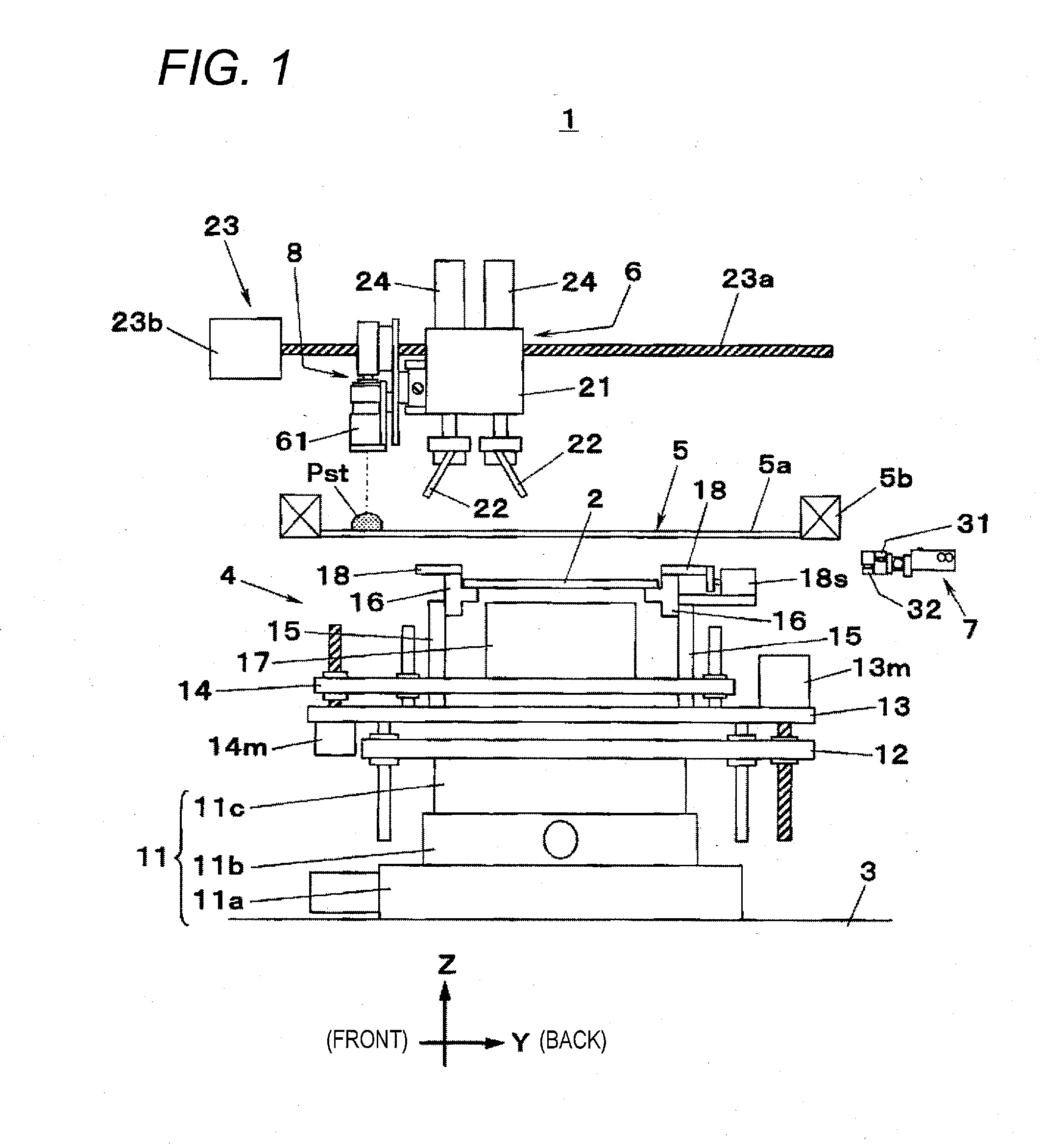

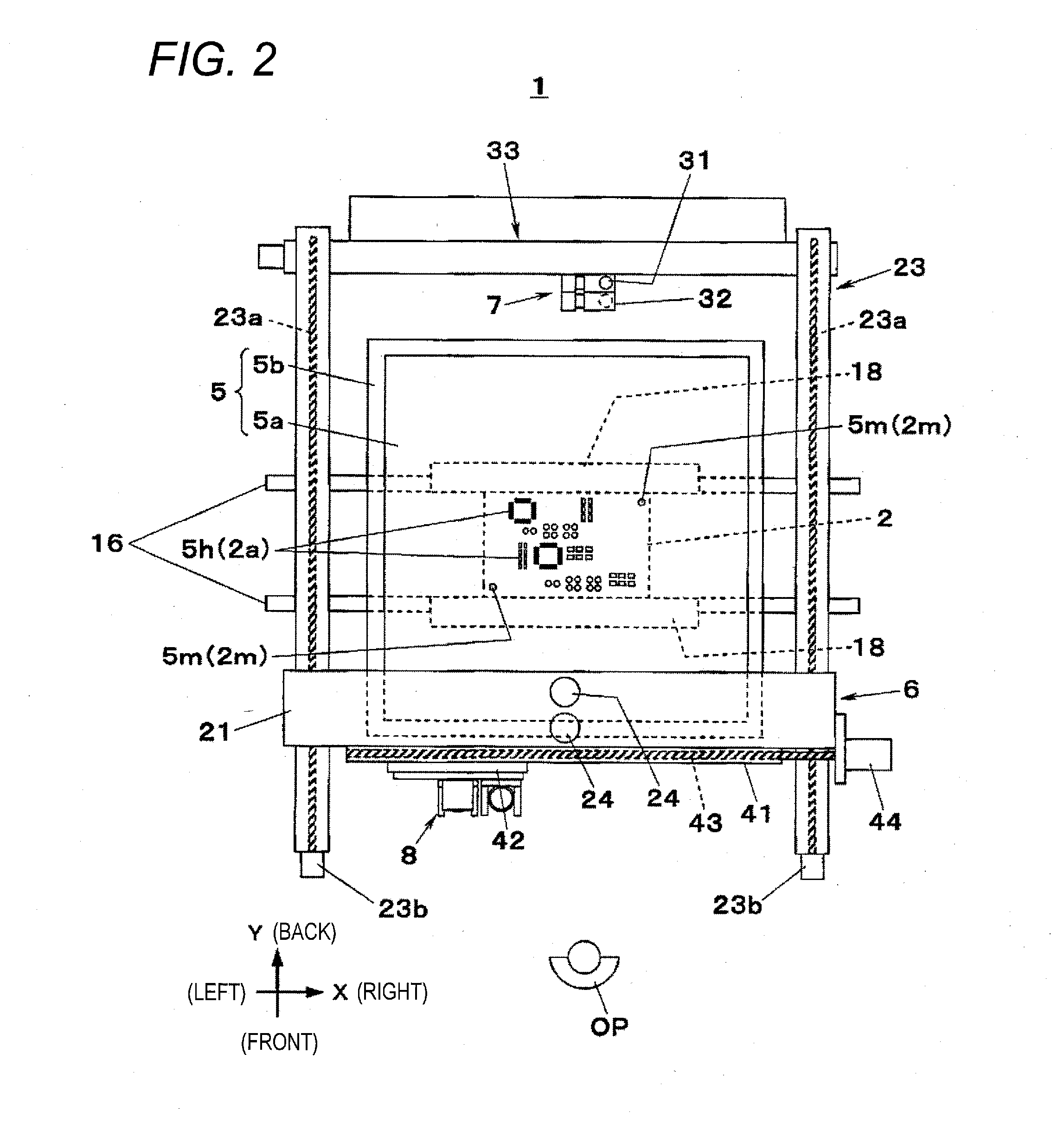

Paste supply apparatus, screen printing machine, paste supply method and screen printing method

ActiveUS20140366754A1Improve work efficiencyInking apparatusLiquid surface applicatorsScreen printingEngineering

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

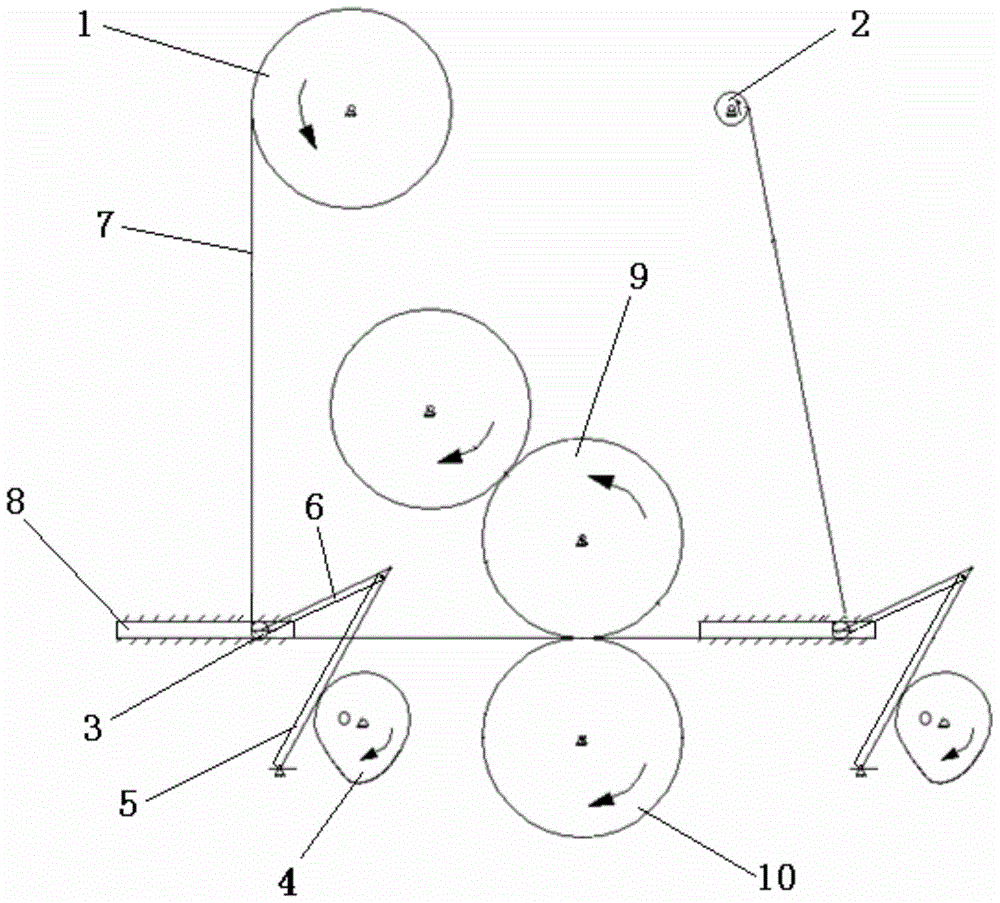

Method and device for obtaining holographic patterns and printing machine with same

InactiveCN101797850AShorten the timePrevent fallingRotary pressesOther printing apparatusEngineeringPrinting press

Owner:BROTECH GRAPHIC

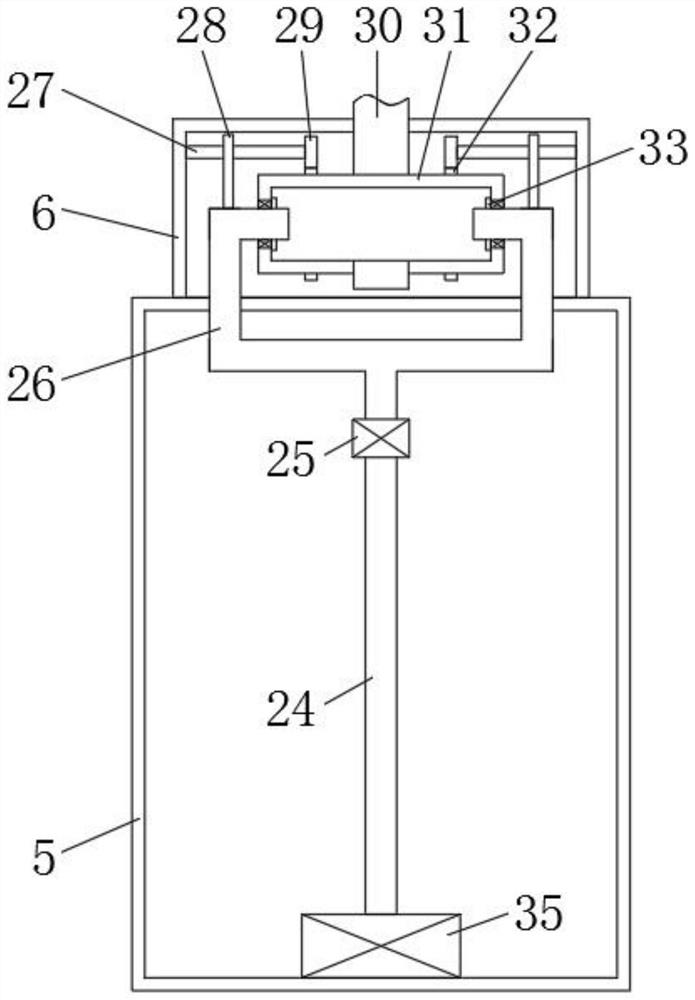

Automatic ink adding device for packaging printing machine

InactiveCN112477419AImprove work efficiencyQuick changePrinting press partsEngineeringPrinting press

Owner:芜湖恒丰彩印包装股份有限公司

Spray device

Owner:SHANGHAI ELECTRICGROUP CORP

Closed scraper device used for gravure printing machine

InactiveCN104512092AInk storage space is smallIncrease viscosityRotary intaglio printing pressSolvent evaporationEngineering

Owner:SHAANXI BEIREN PRINTING MACHINERY

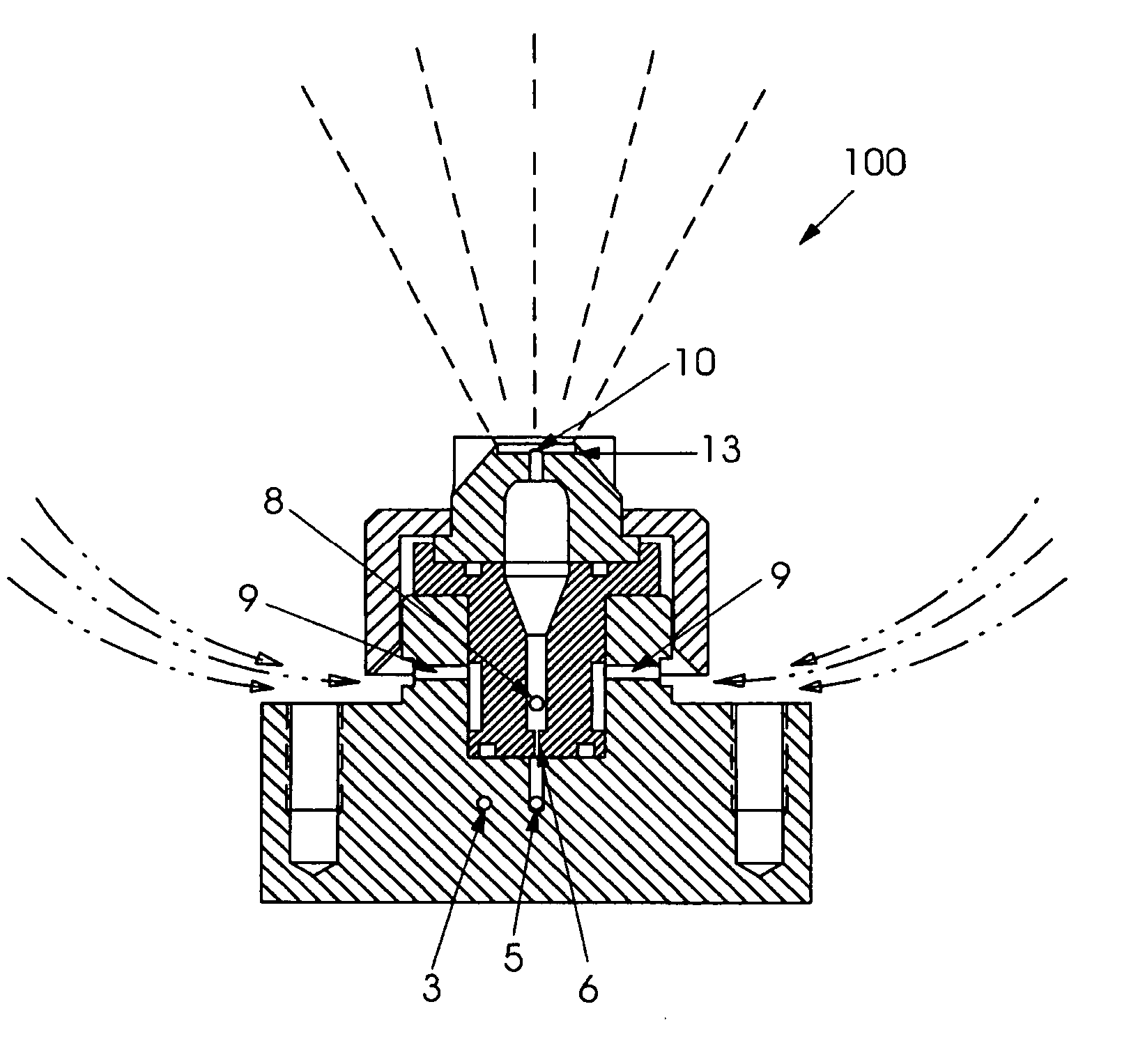

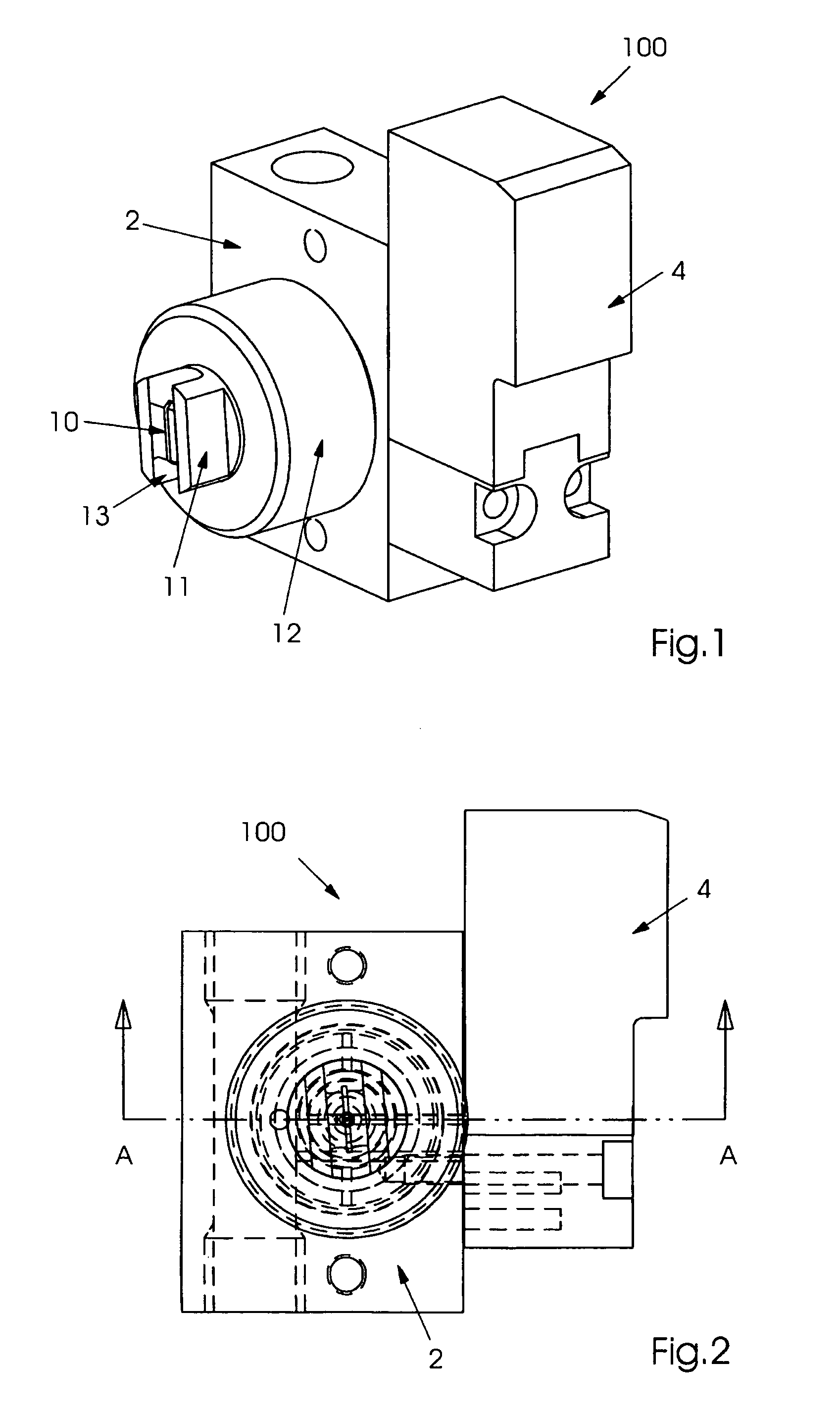

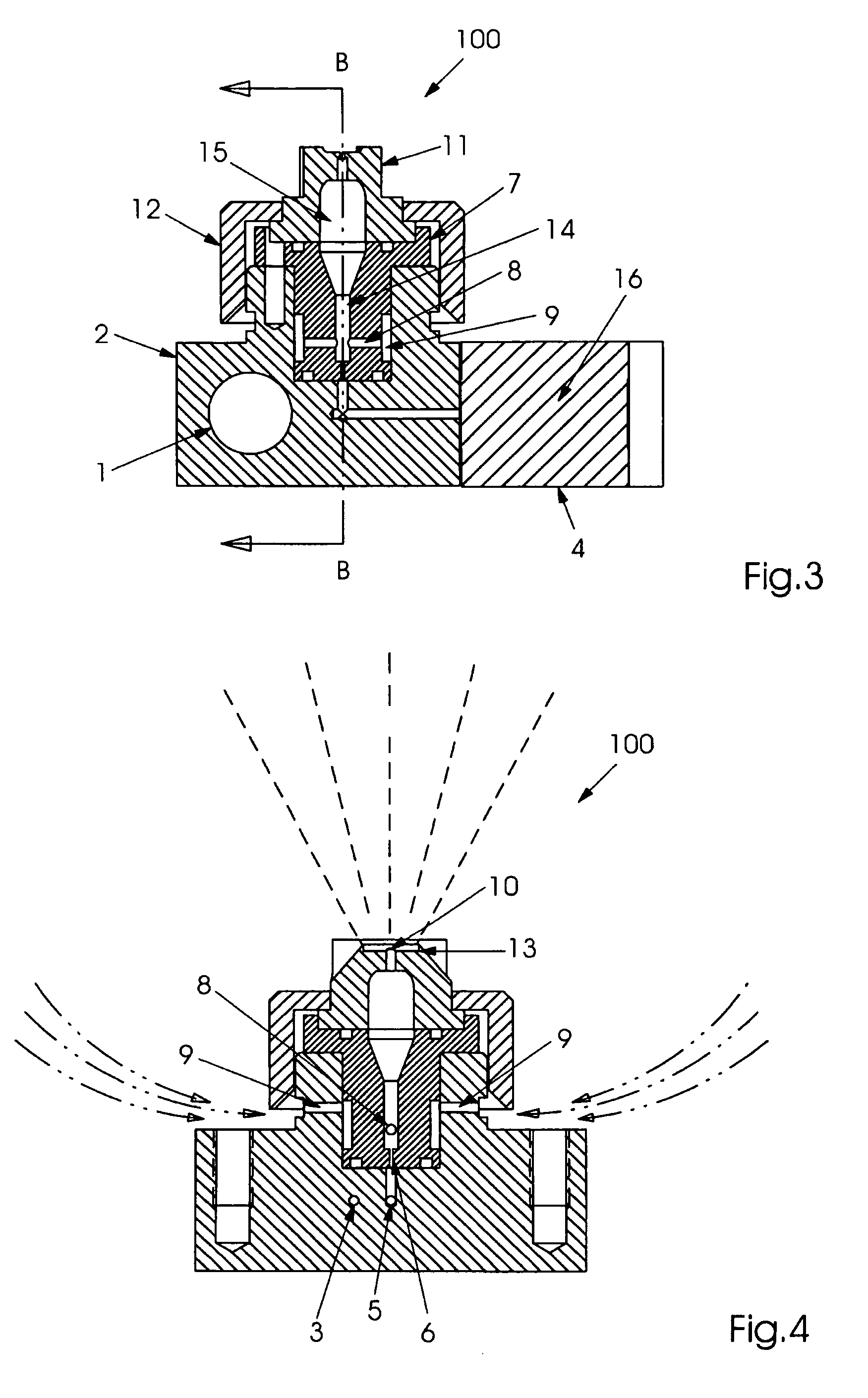

Process and printing machine for the use of liquid print colors

InactiveUS20050231582A1Easy to handleAvoid adversely affecting transferenceDevelopersMicrowave heatingEngineeringPrinting press

Owner:EASTMAN KODAK CO

Apparatus for feeding foil of printing machine with tension

InactiveUS20100294145A1Easy tension adjustmentAvoid damageMechanical working/deformationRotary pressesVacuum pressurePrinting press

Owner:SONG BYUNG JUN

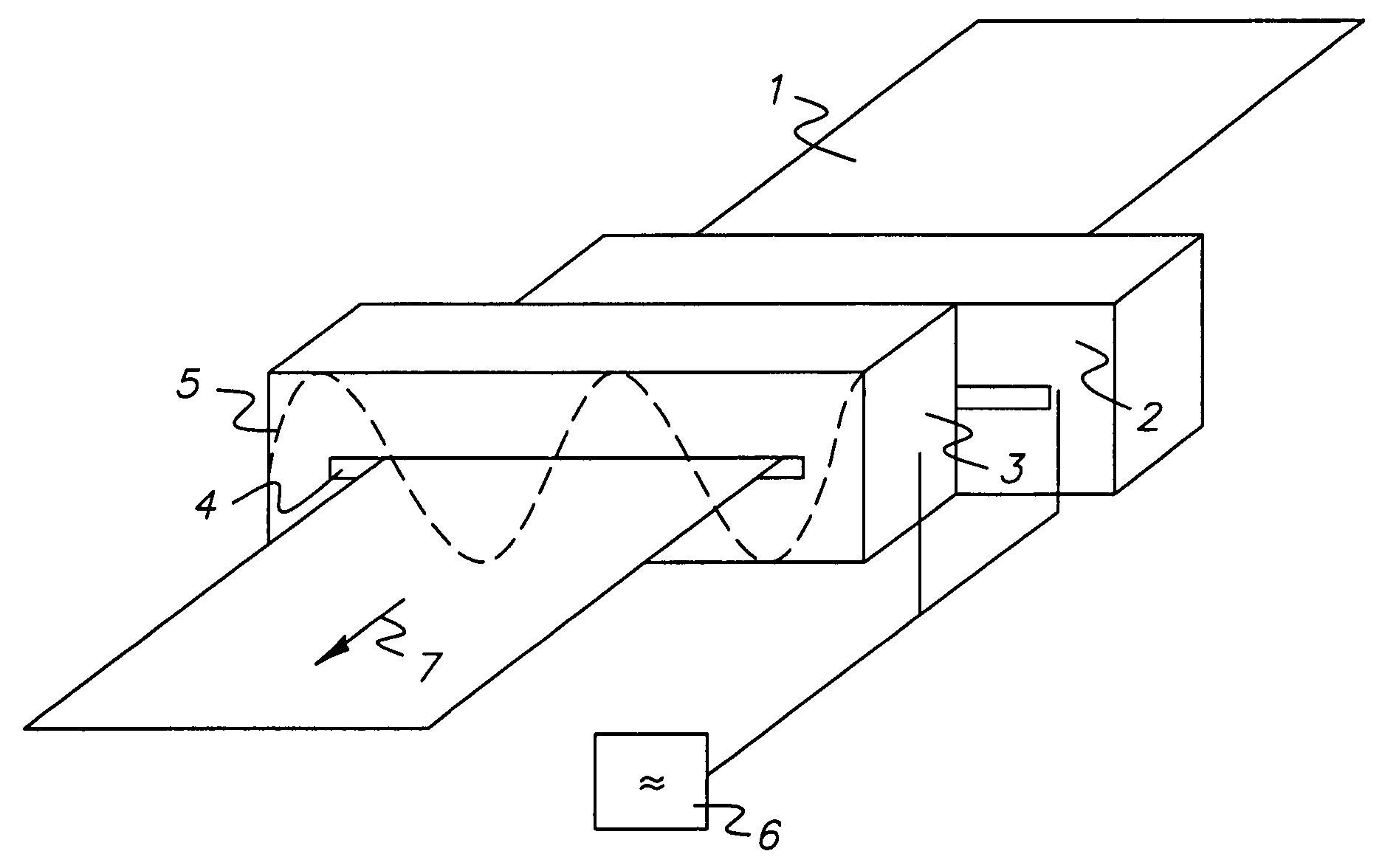

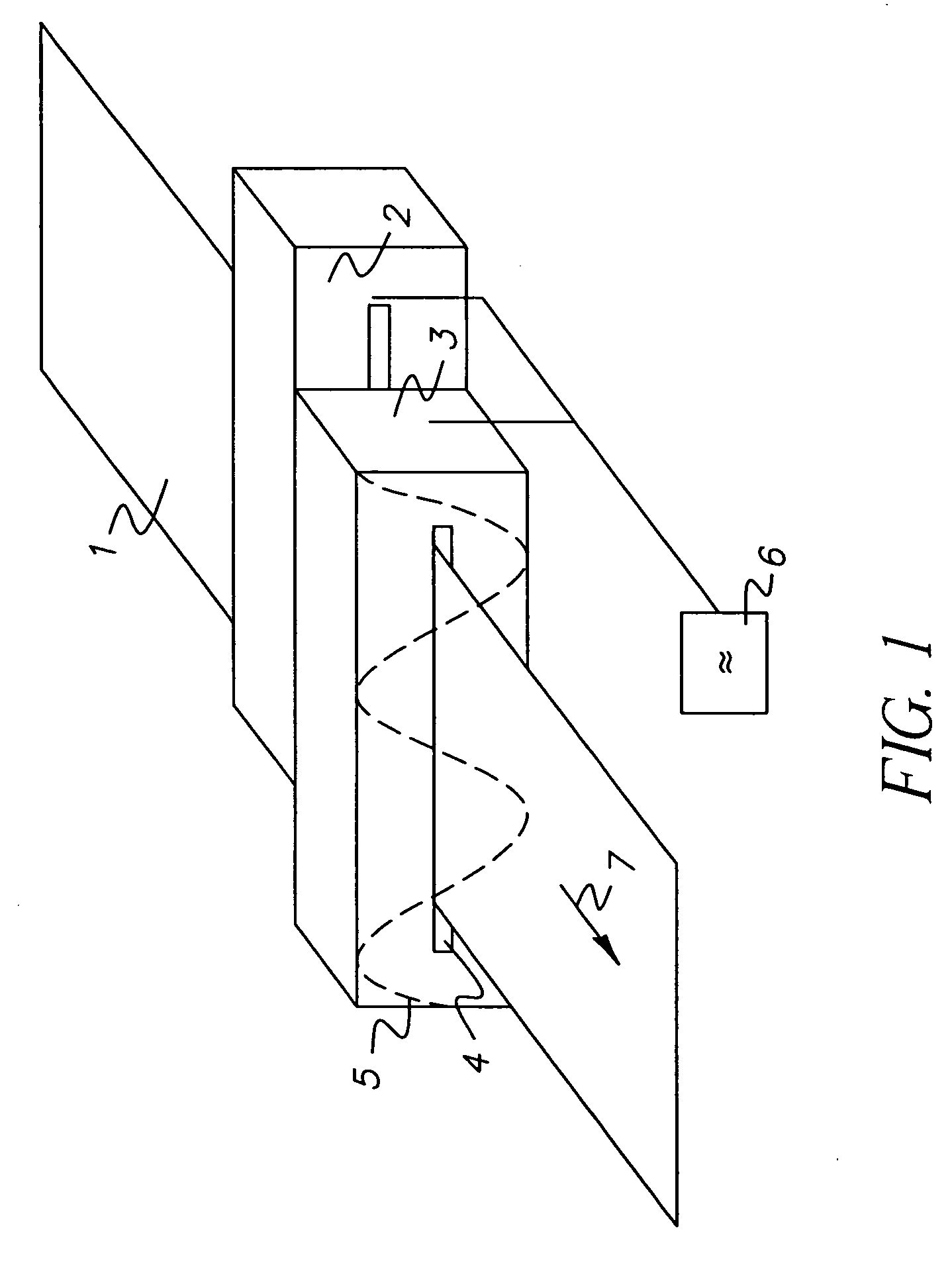

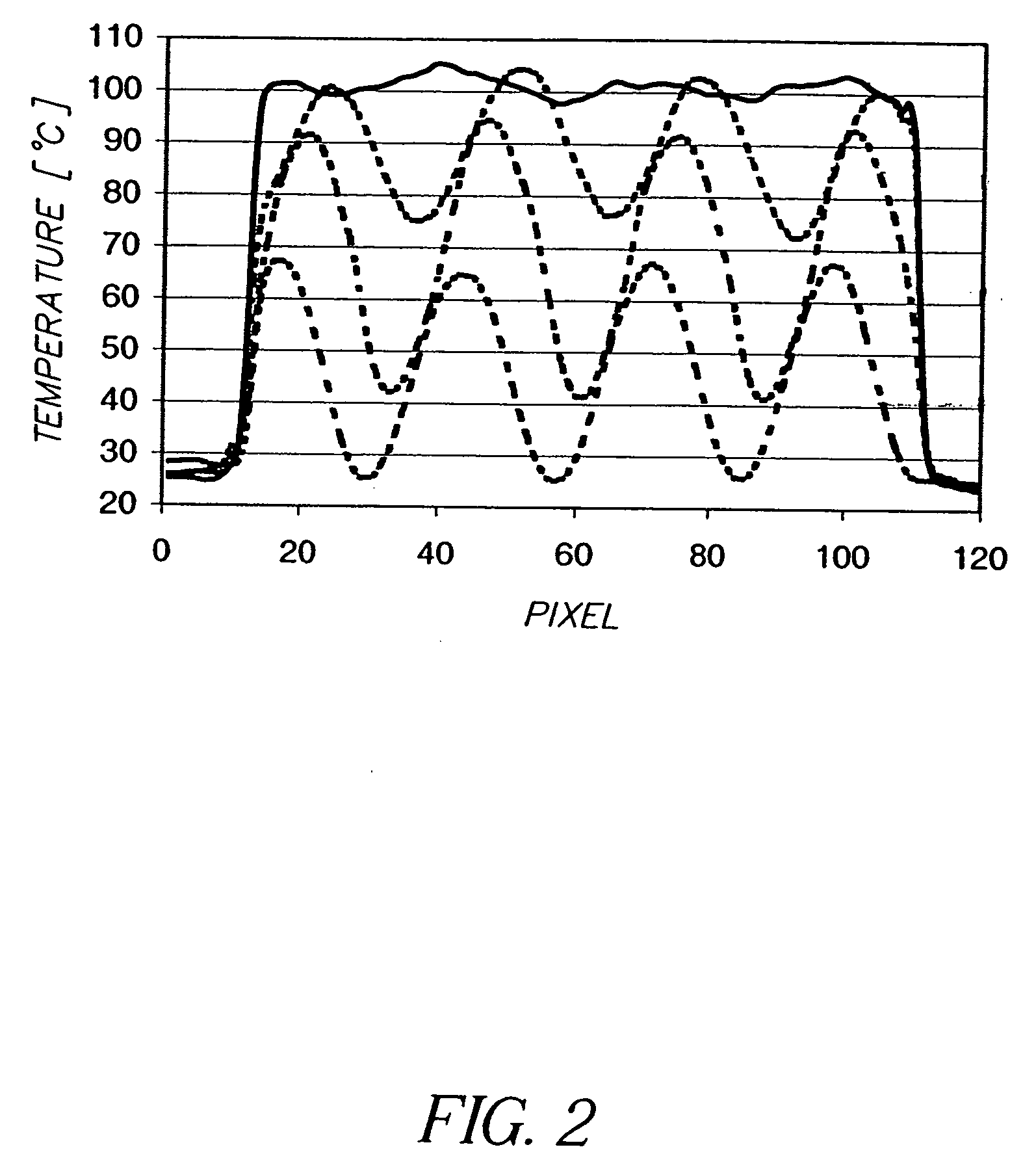

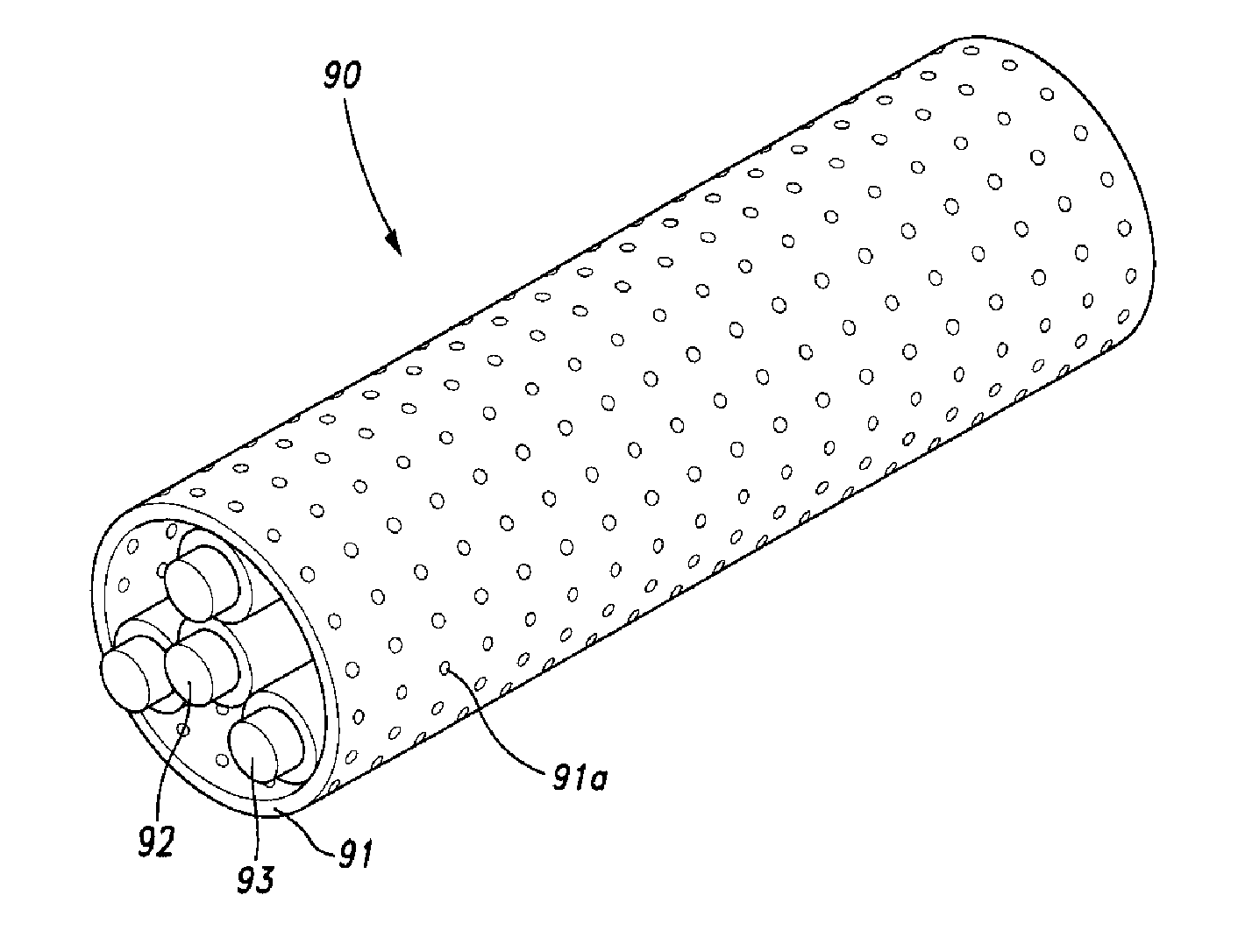

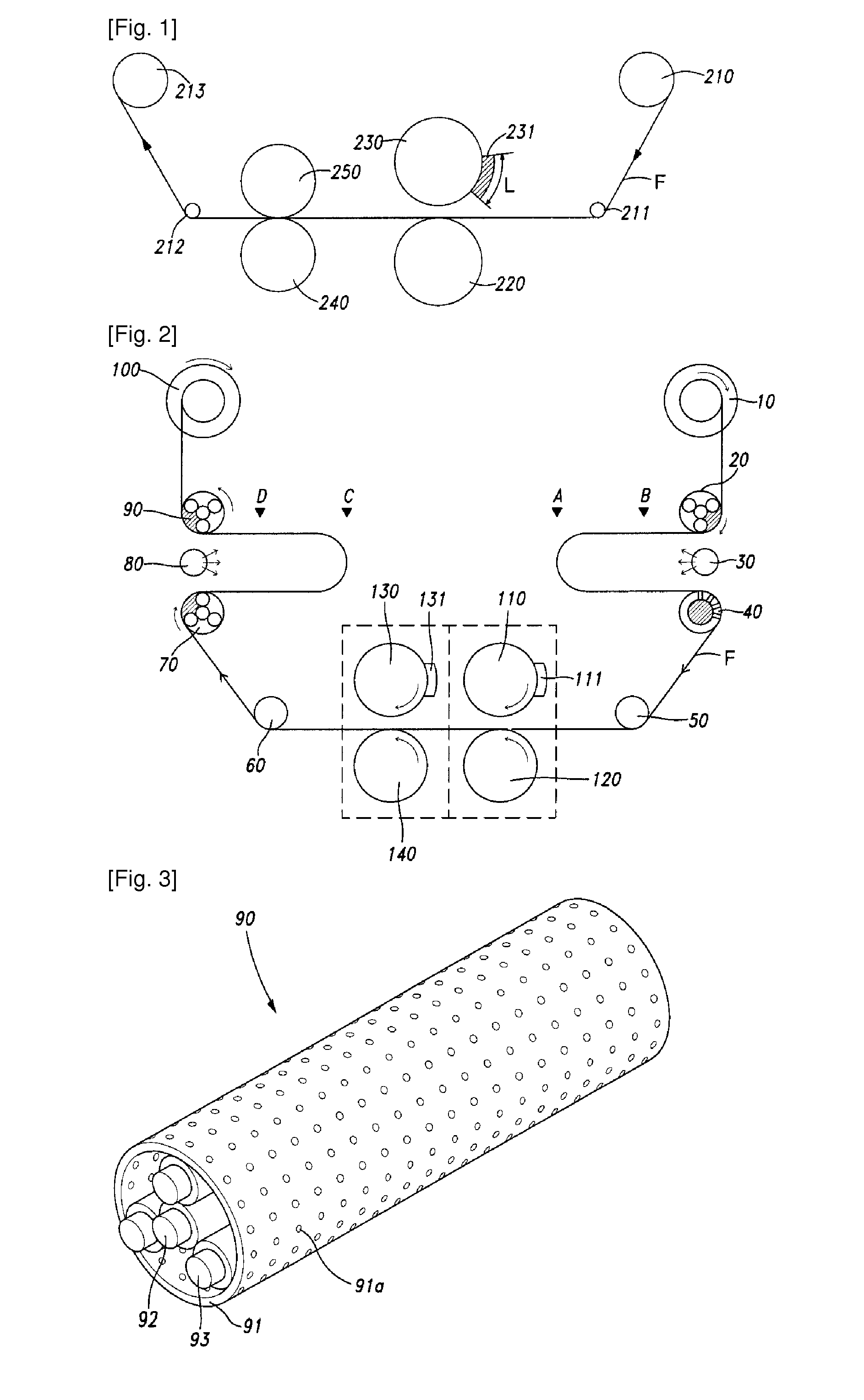

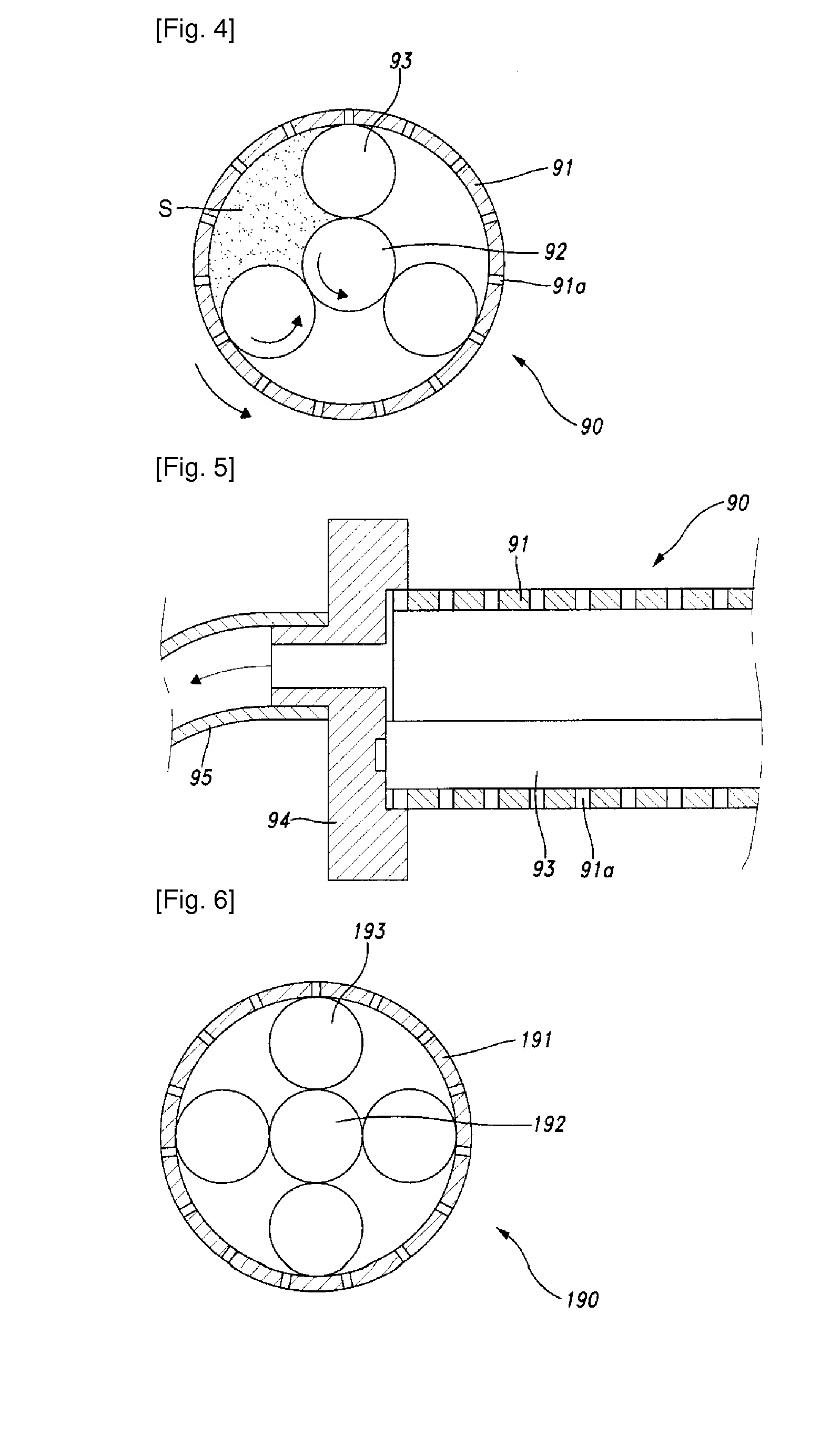

Device and method for controlling the temperature of a rotating body

A cylinder of a printing press is provided with an axial bore in which a fluid supply line is supported by spacers forming a return duct having an annular cross section, so that the inlet and the outlet of the fluid are at the same end of the cylinder.

Owner:MANROLANAD AG

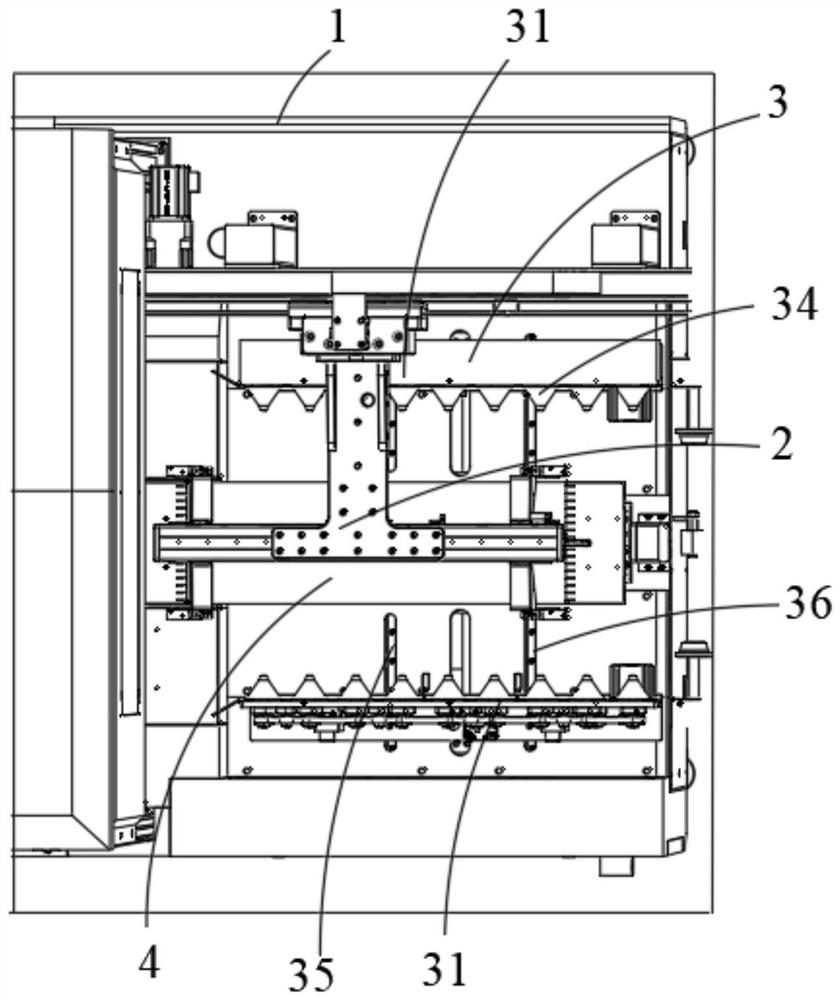

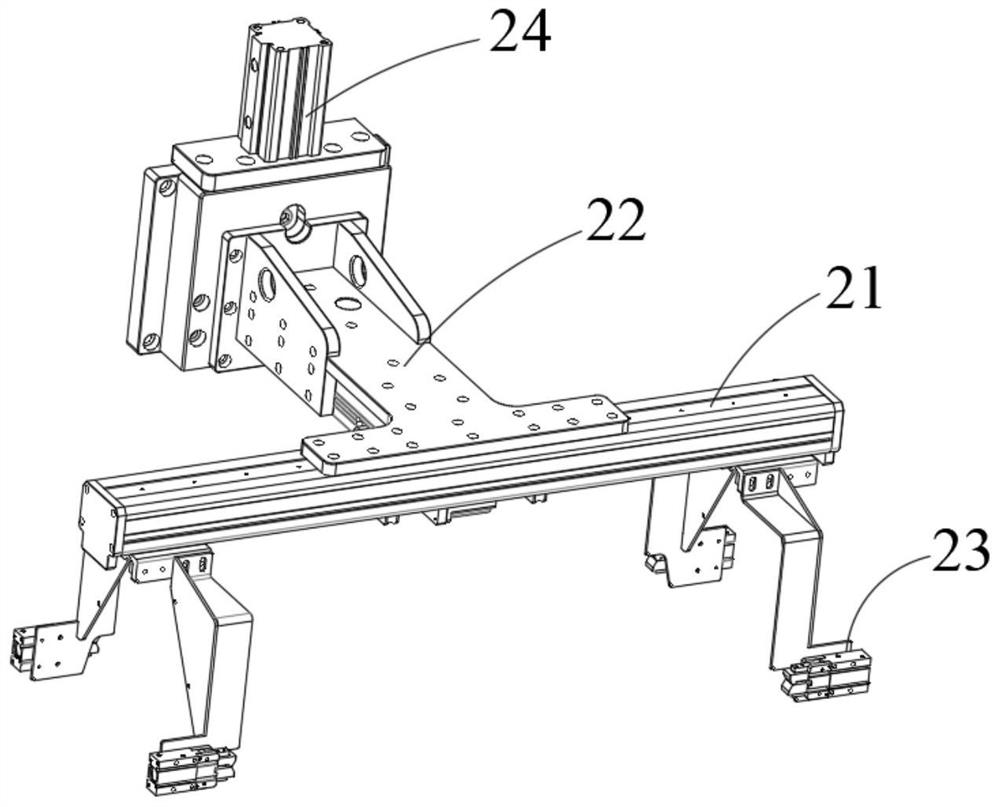

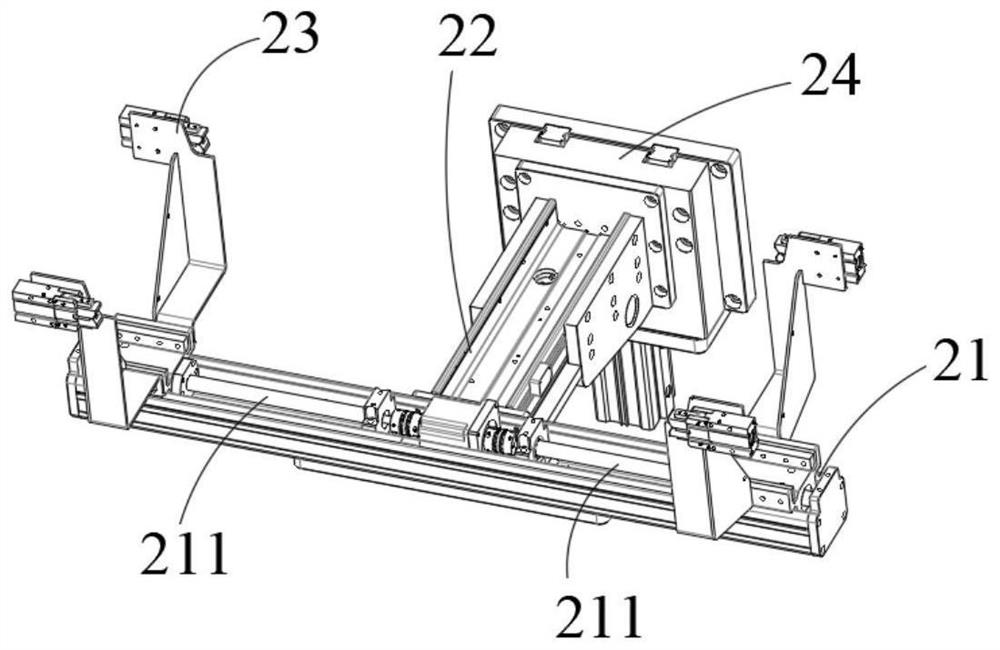

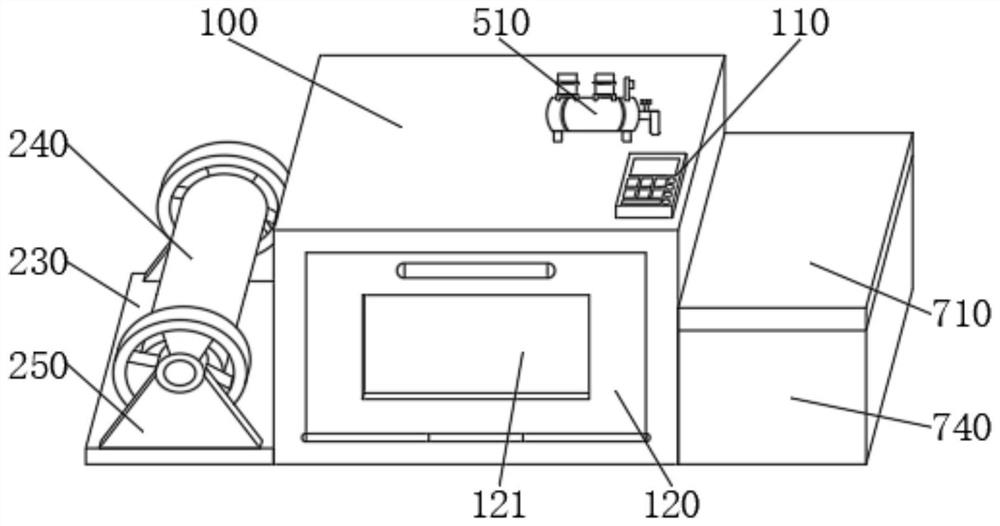

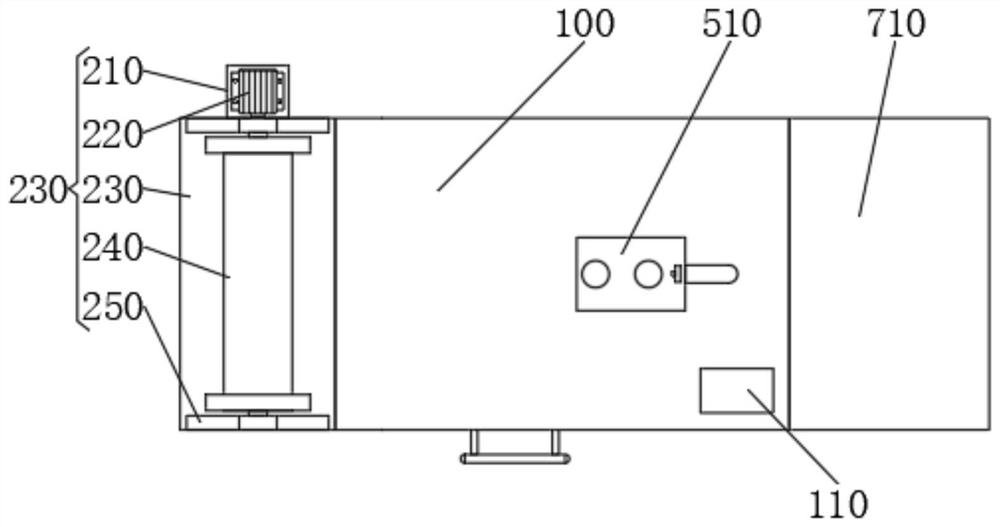

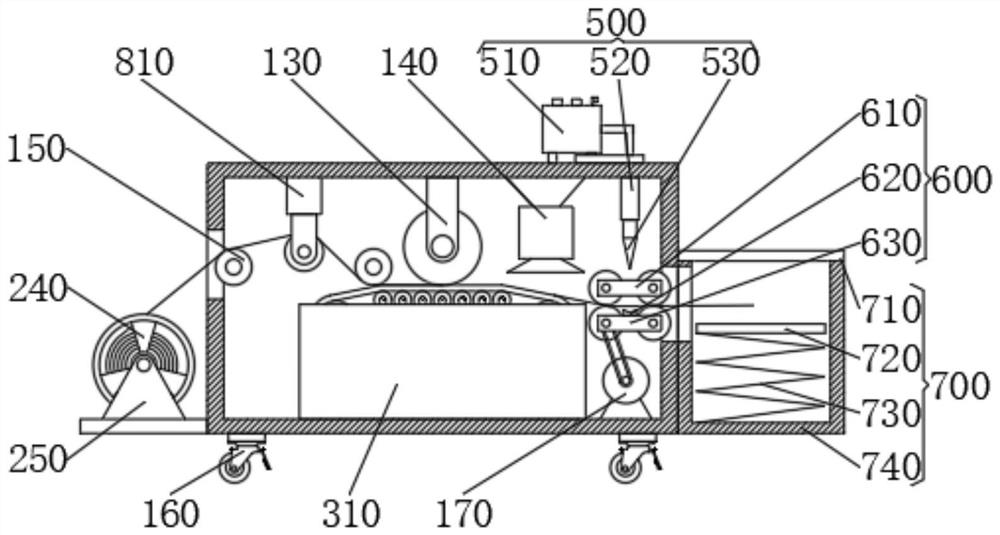

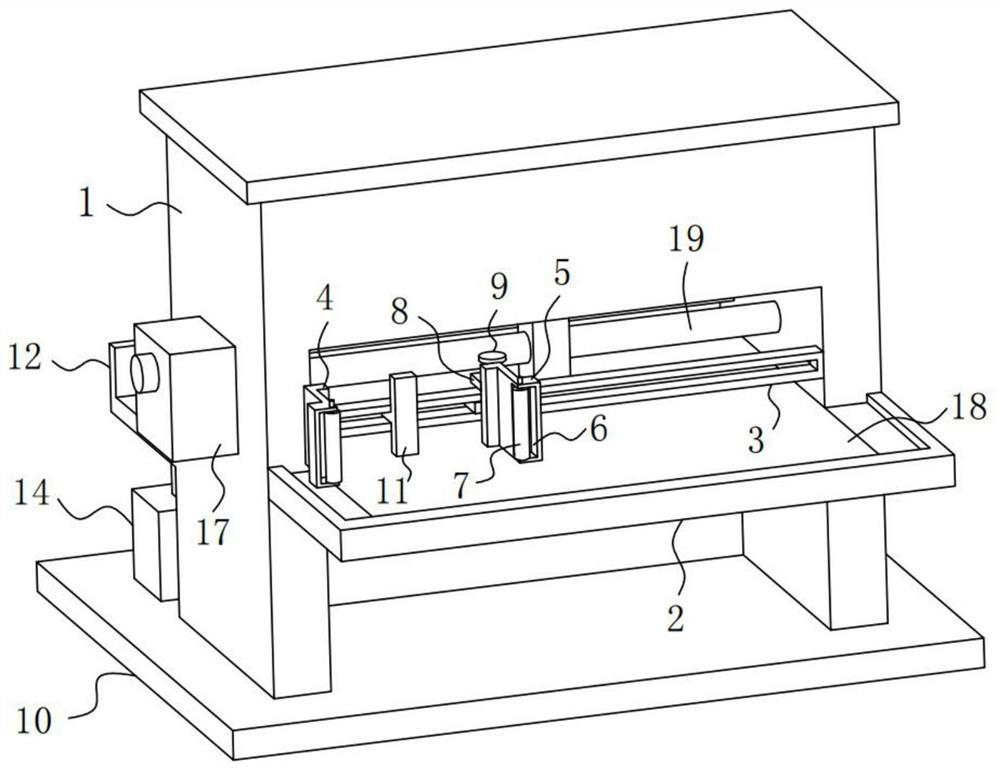

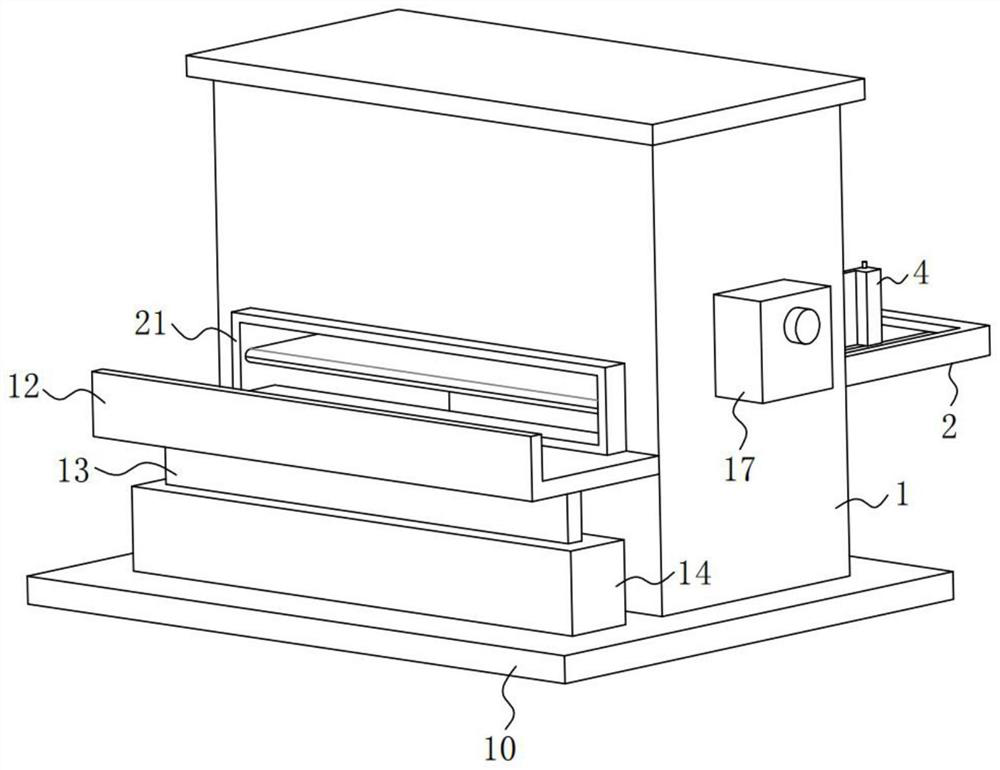

Automatic printing production device for thin plates

ActiveCN112848664AAddressing transfer adaptability issuesRealize fully automatic integrated processing processScreen printersOther printing apparatusPrinting pressMachining process

Owner:广东金玛印刷机械有限公司

Printing machine anti-sticking mechanism

InactiveCN104773589APrevent the problem of sticking to each otherStable structurePile receiversPulp and paper industryEngineering

The invention discloses a printing machine anti-sticking mechanism, which comprises a paper discharge opening of a printing machine body, a paper collecting table and a control panel, wherein the control panel is positioned on an outer panel arranged beside the paper discharging opening of the printing machine body, a first magnet is respectively embedded in four corner parts of the paper collecting table, in addition, the four first magnets are in a rectangular shape, four support frames are vertically placed on the paper collecting table, the four support frames are respectively positioned above the four first magnets, one second magnet is respectively embedded in the upper part and the lower part of each support frame, a bottom plate is horizontally placed above the four support frames, a third magnet is respectively embedded in the four corner parts of the bottom plate, the third magnets and the second magnets are in one-to-one corresponding arrangement, the first magnets and the third magnets have the same magnetisms, and the first magnets and the second magnets have the opposite magnetisms. The printing machine anti-sticking mechanism has the advantages that the support frames and the bottom plate are arranged by using the magnetism, the structure is firm, the problem of mutual adhesion between paper positioned at the lower side is effectively prevented, the printing quality is improved, the labor is saved, in addition, the structure is simple, the manufacturing is convenient, the manufacturing cost is low, and the printing machine anti-sticking mechanism is suitable for practical use.

Owner:ANHUI XINYAN PRINTING CO LTD

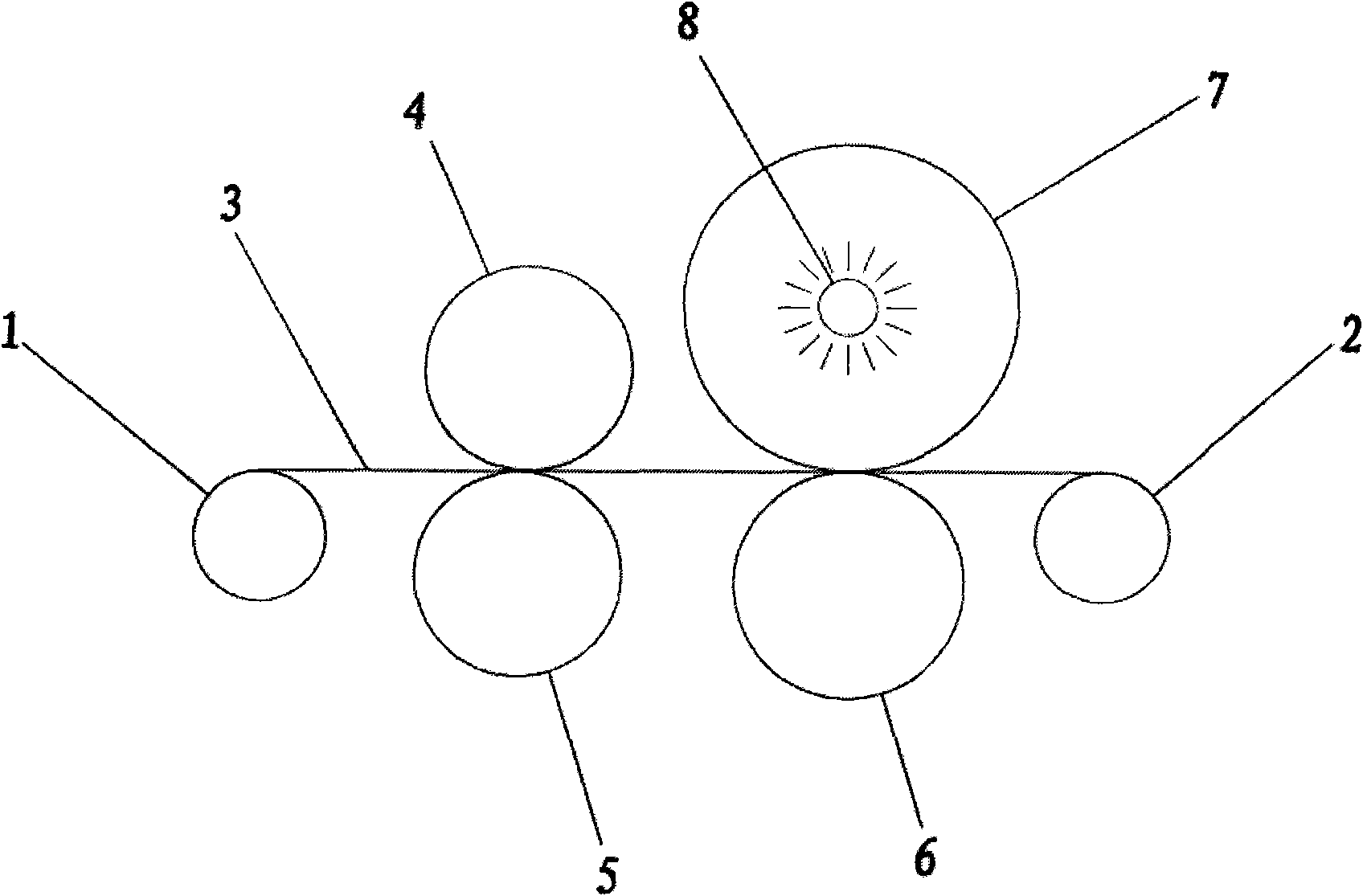

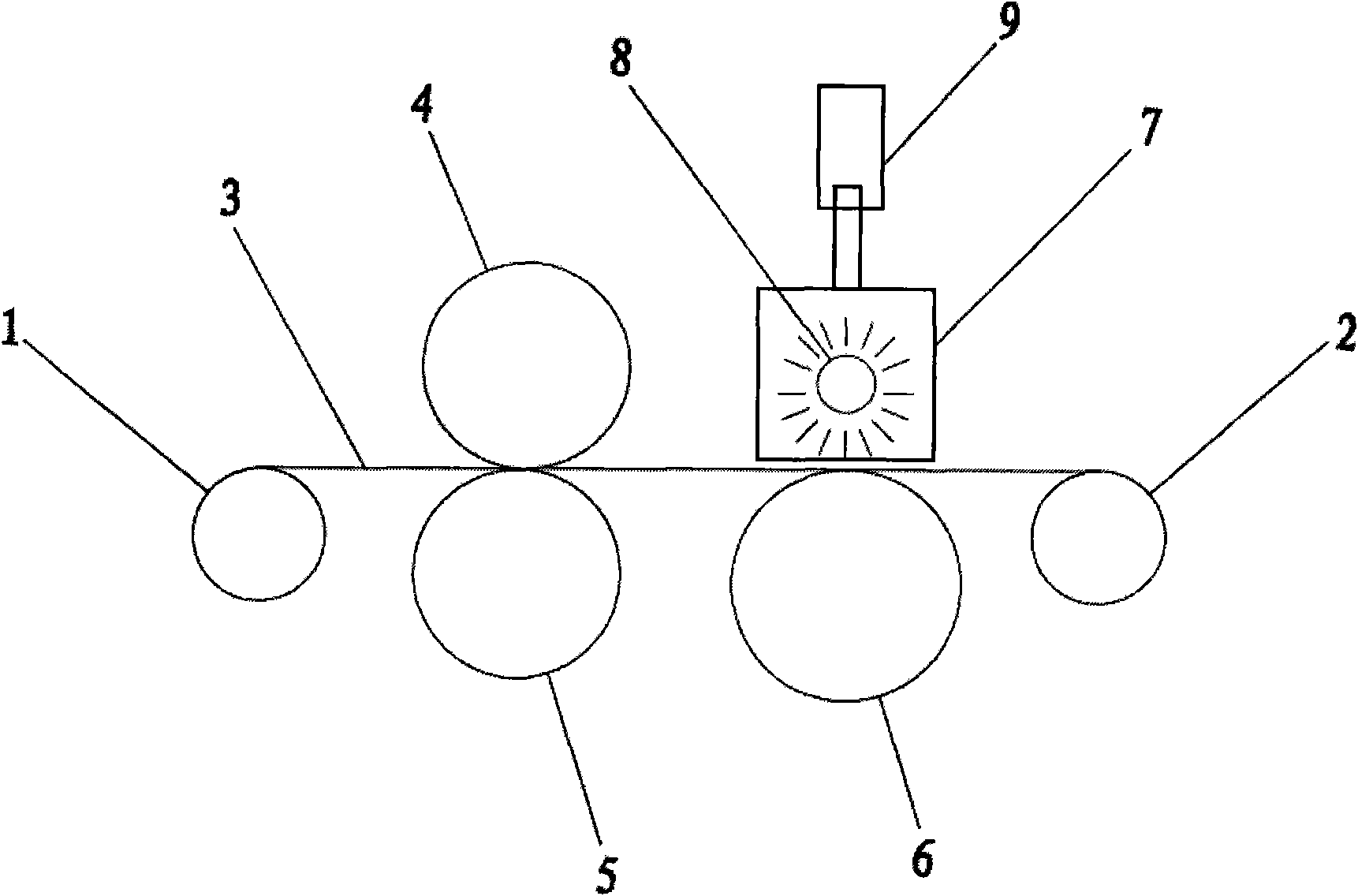

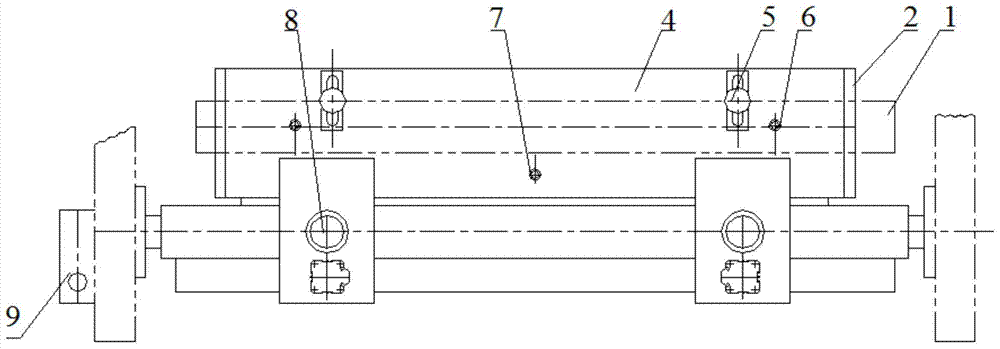

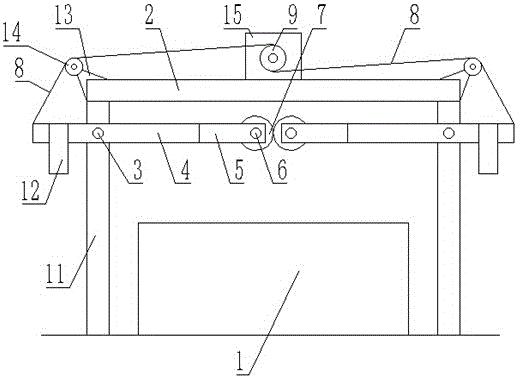

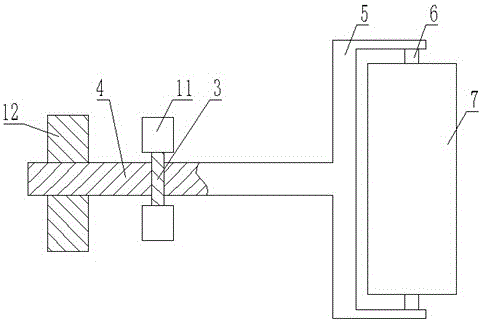

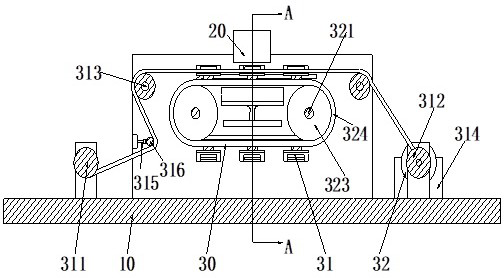

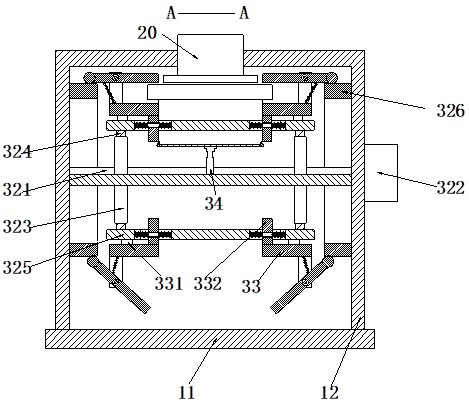

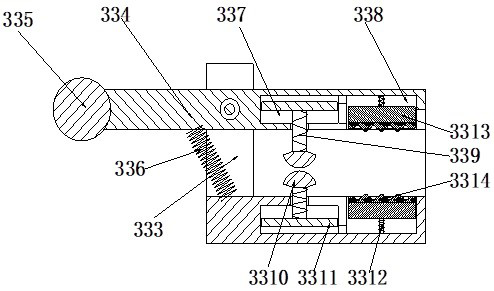

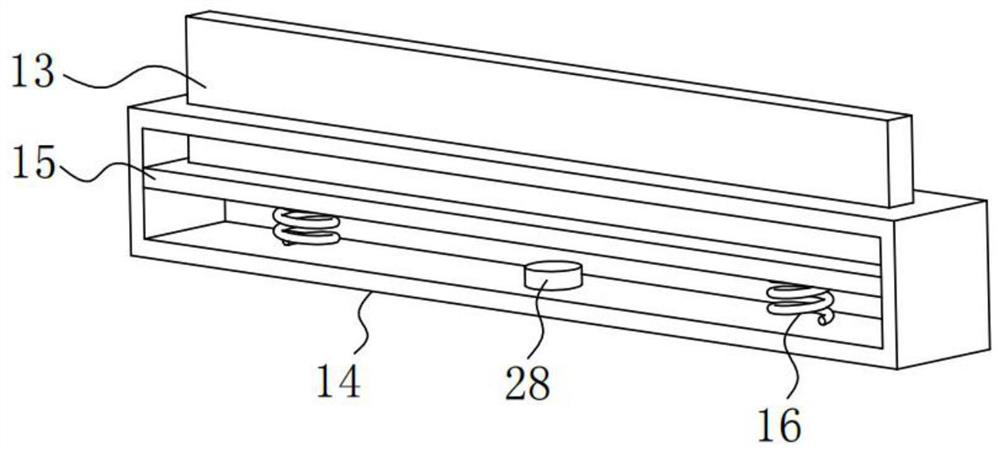

Tension control device of flexographic printing press

The invention provides a tension control device of a flexographic printing press. The tension control device comprises a first supporting roller and a second supporting roller, and also comprises a shaft base, an adjusting roller, a sliding base, a compression spring, an anti-breaking mechanism and a fixed base, wherein the shaft base is slidably arranged on a main frame; the adjusting roller is rotationally arranged on the shaft base; a printing substrate is sequentially wound on the first supporting roller, the adjusting roller and the second supporting roller; the sliding base is slidably arranged on the main frame; the compression spring is arranged between the sliding base and the shaft base; the anti-breaking mechanism is used for preventing the printing substrate from breaking due to excessive instantaneous tension; the anti-breaking mechanism comprises a moving base, a propping block, an impact rod and a linkage assembly; the moving base is slidably arranged on the main frame;the impact rod is telescopically arranged on the moving base; the propping block is movably arranged on the front side of the moving base through the linkage assembly; the propping block abuts againstthe tail end of the sliding base; the fixed base is fixedly arranged on the main frame; the fixed base is connected with an adjusting knob; and a screw rod of the adjusting knob abuts against the moving base. The tension control device of the flexographic printing press provided by the invention can effectively avoid the breakage of the printing substrate due to excessive instantaneous tension.

Owner:HENAN HUAGANG PRINTING

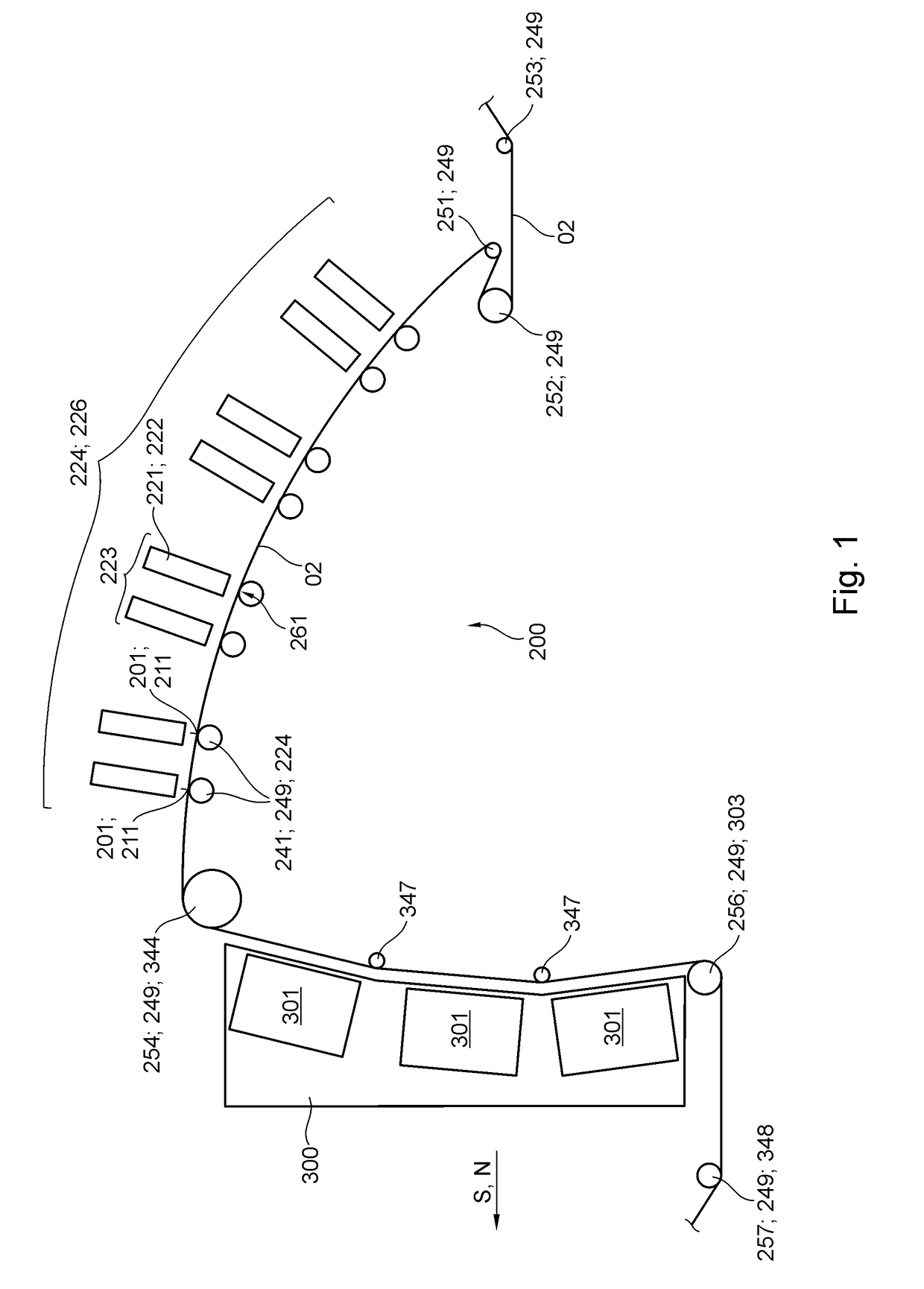

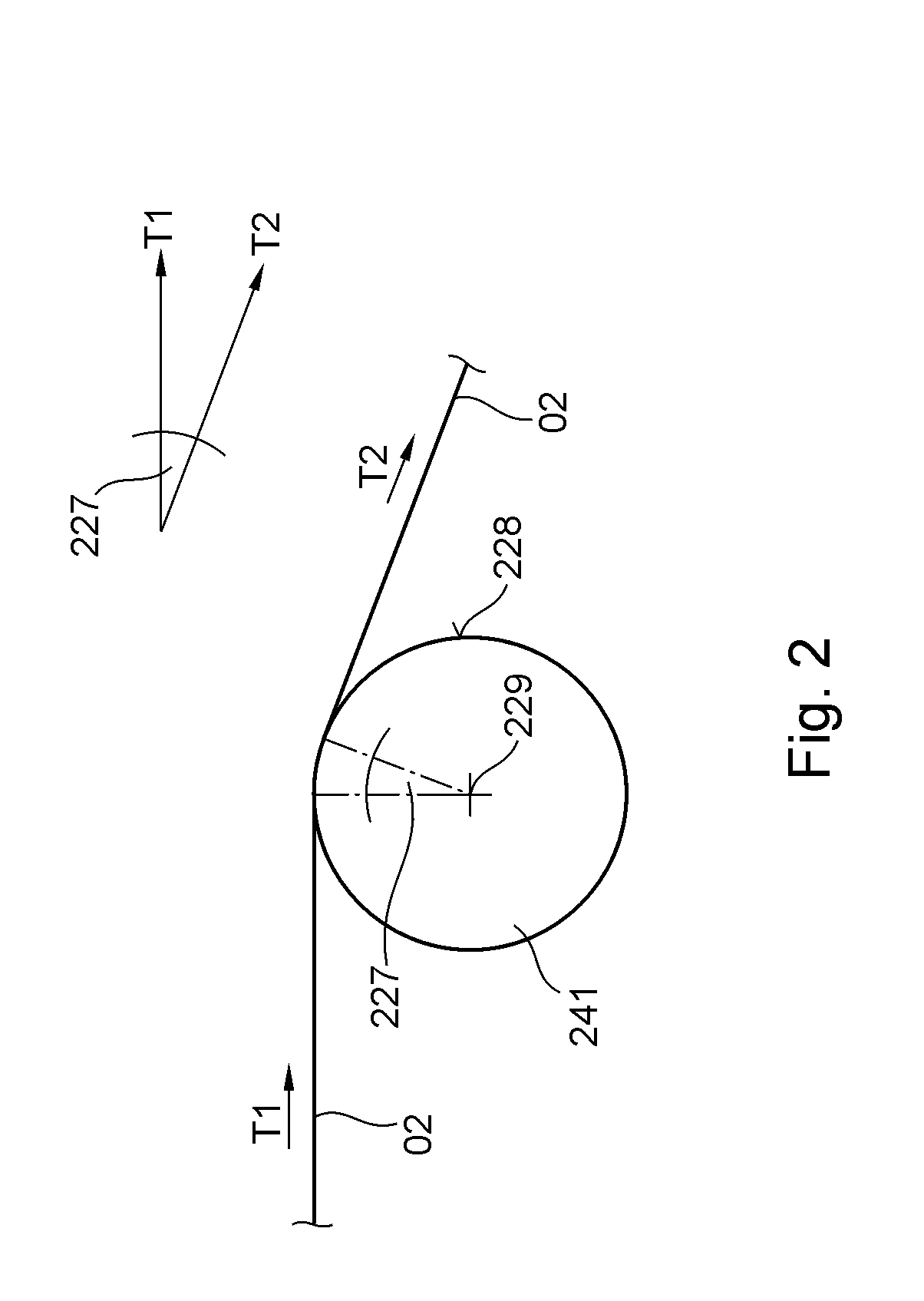

Printing machine having at least one printing assembly and at least one dryer unit and a method for operating a printing machine

ActiveUS20180229511A1Large maintenance spaceLarge widthOther printing apparatusPrinting after-treatmentEngineeringOutput device

Owner:KOENIG & BAUER AG

Paper pressing device for printer

Owner:HUZHOU JIANING PRINTING

Self-shearing packaging decoration printing machine

InactiveCN113400790AAvoid shakingAvoid jammingRotary pressesOther printing apparatusStructural engineeringPrinting press

Owner:安徽省三环康乐包装材料有限公司

A high-efficiency ink printing machine

ActiveCN111660669BValid print jobQuality improvementOther printing apparatusPrinting pressMechanical engineering

Owner:湖南鹤祥包装有限公司

Printing machine with code spraying and up-and-down printing functions for cartons

Owner:浙江中包派克包装有限公司

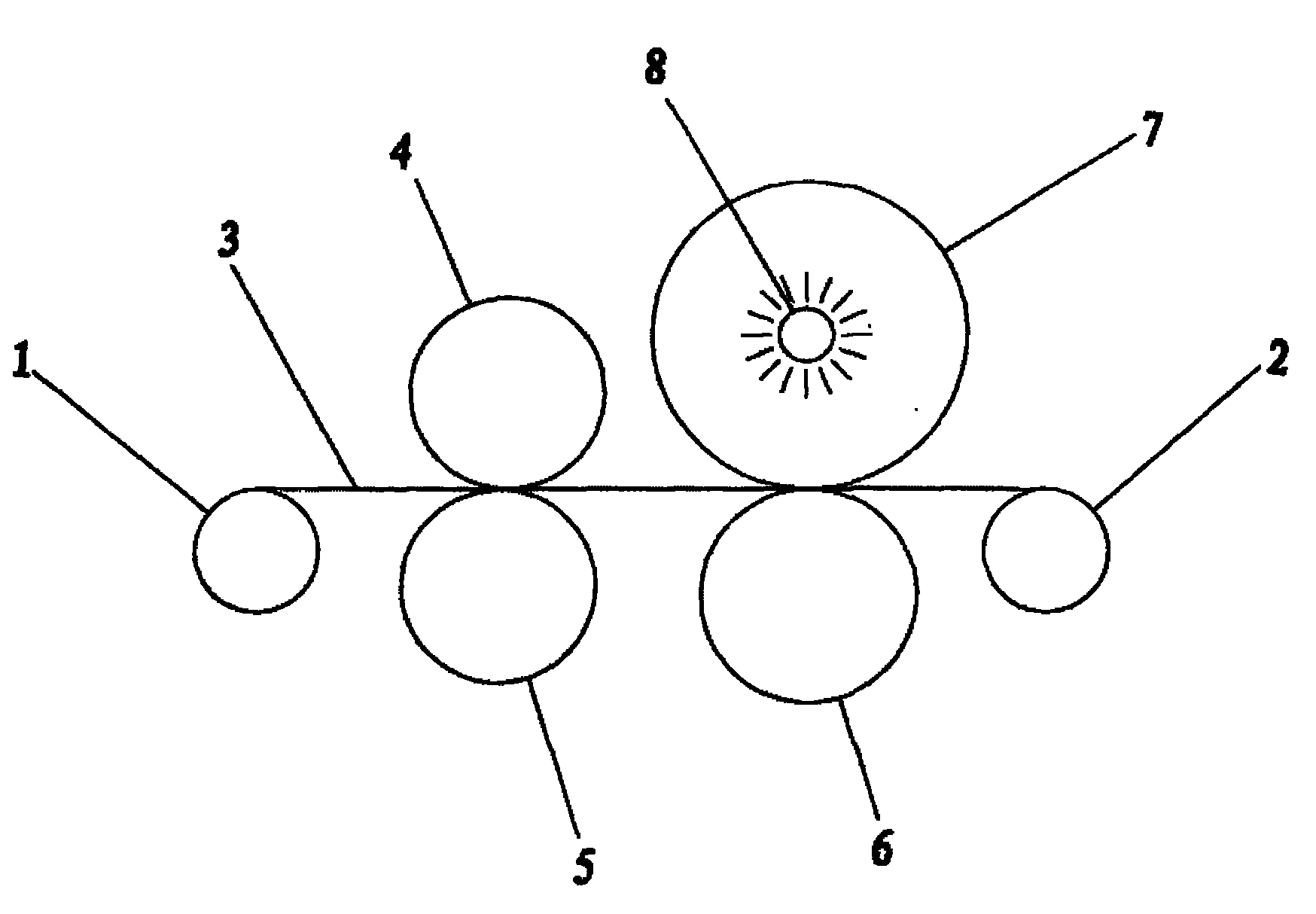

Disposable printing roller

InactiveUS20050061187A1High cost and maintenanceSame durabilityRotary pressesForme preparationPrinting pressComputer engineering

The invention relates to printing rollers that are used in the dry offset printing industry. Presently there are no effective disposable printing rollers designed for use in printing presses used in the dry offset printing industry. The invention comes in different designs depending on the particular press involved. The invention can be manufactured and sold at a cost similar to the resurfacing costs of the present non-disposable printing rollers but is as structurally sound as a non-disposable printing roller. The invention provides the convenience of being disposable saving time and cost to the printer. The high administrative and logistic costs associated with resurfacing printing rollers are eliminated with the present invention. One need only use the disposable printing roller once and simply dispose of it once the roller is no longer useful.

Owner:ENGINEERED PLASTIC SOLUTIONS GRP

Producing partially translucent packaging materials

Owner:EASTMAN KODAK CO

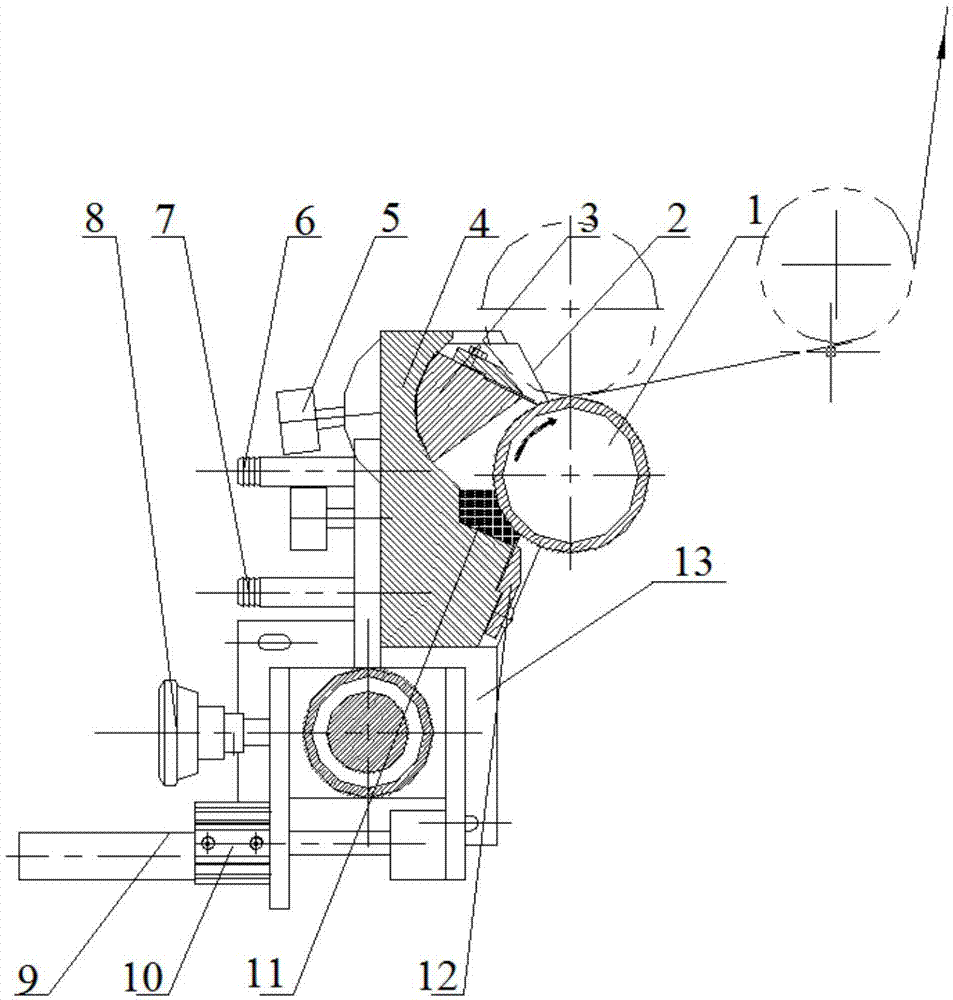

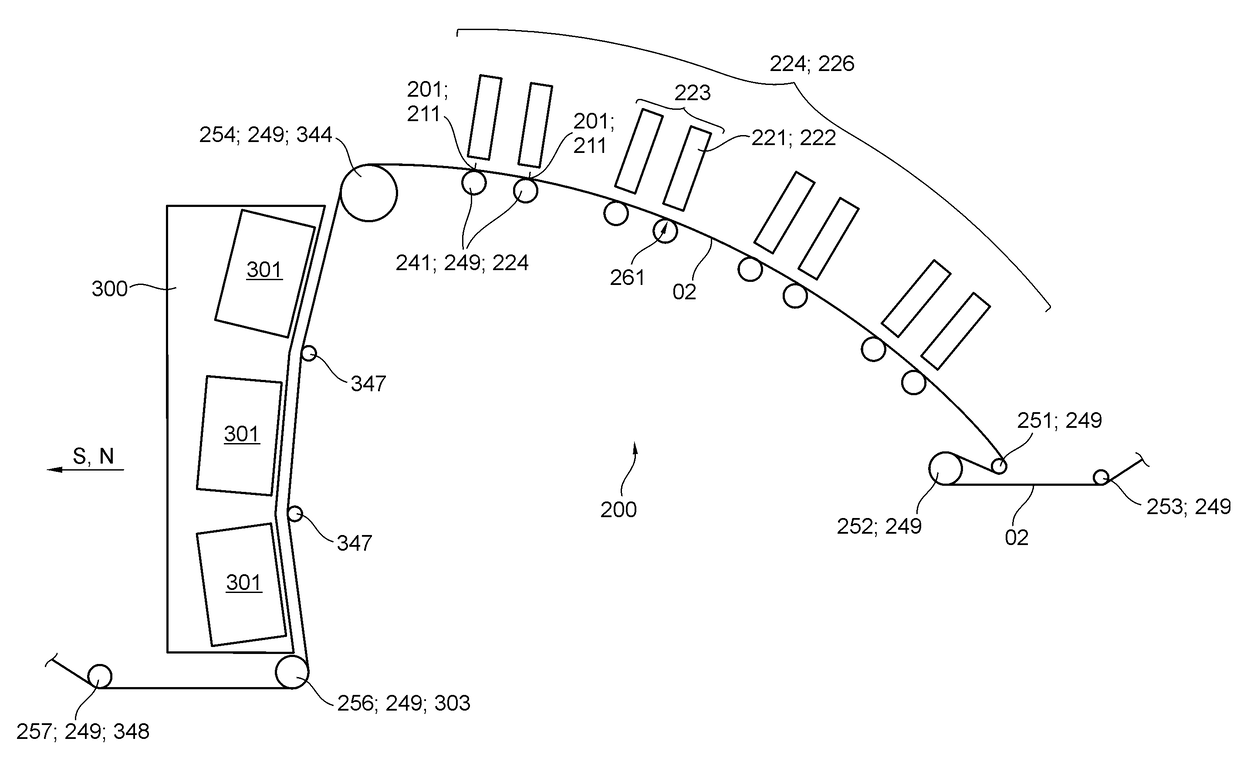

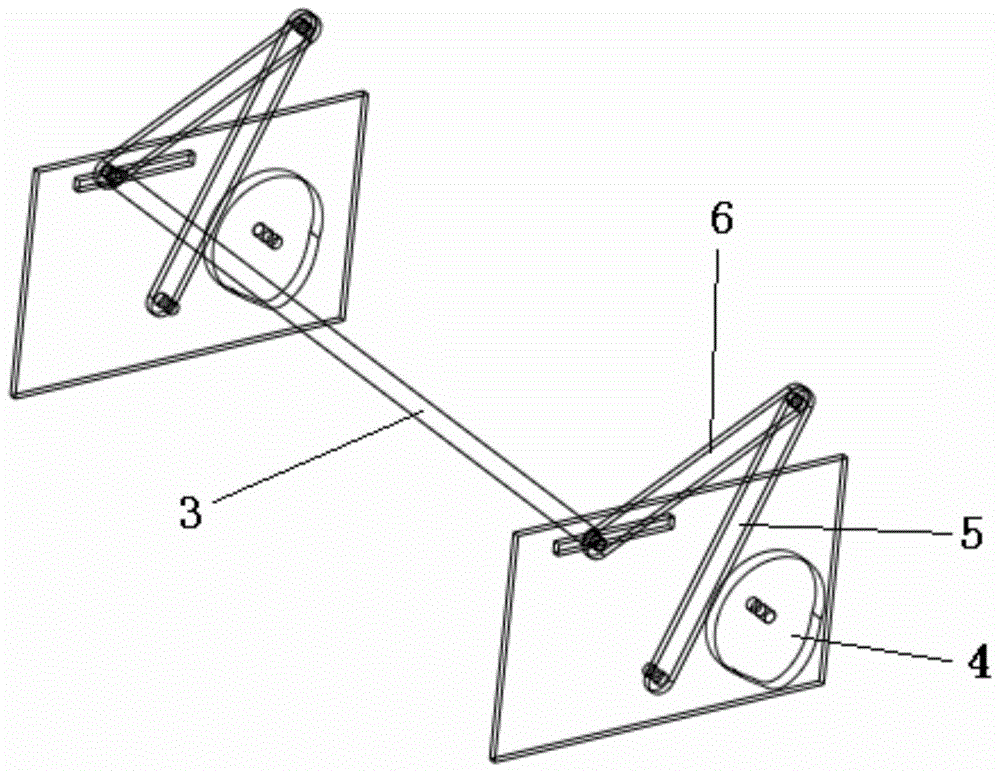

A jumping device for on-line cold ironing of a printing machine

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

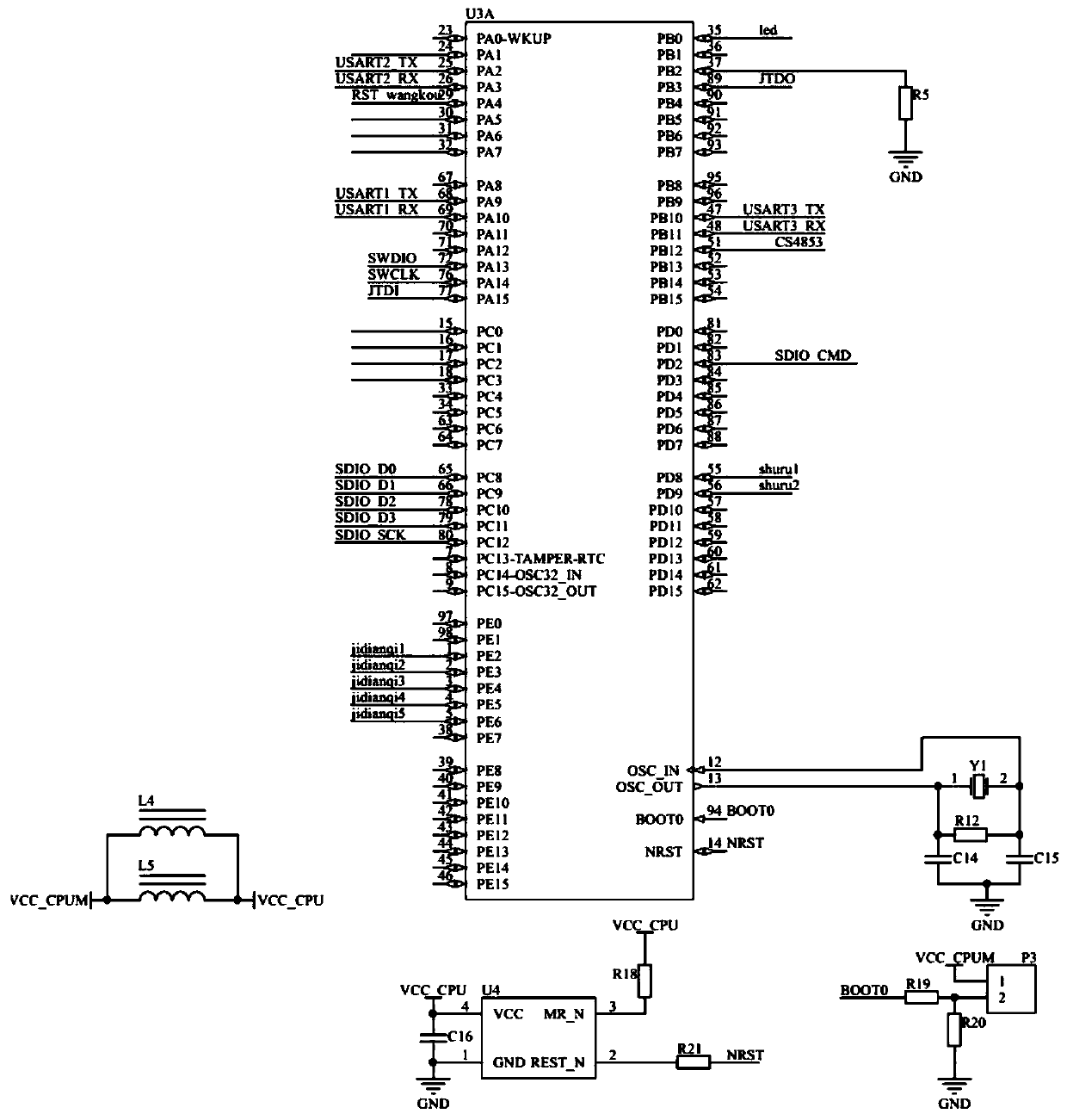

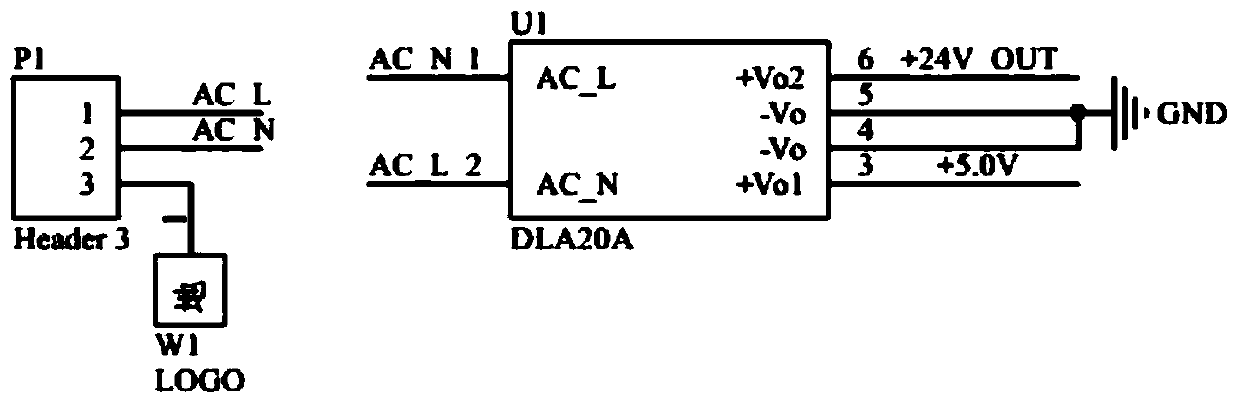

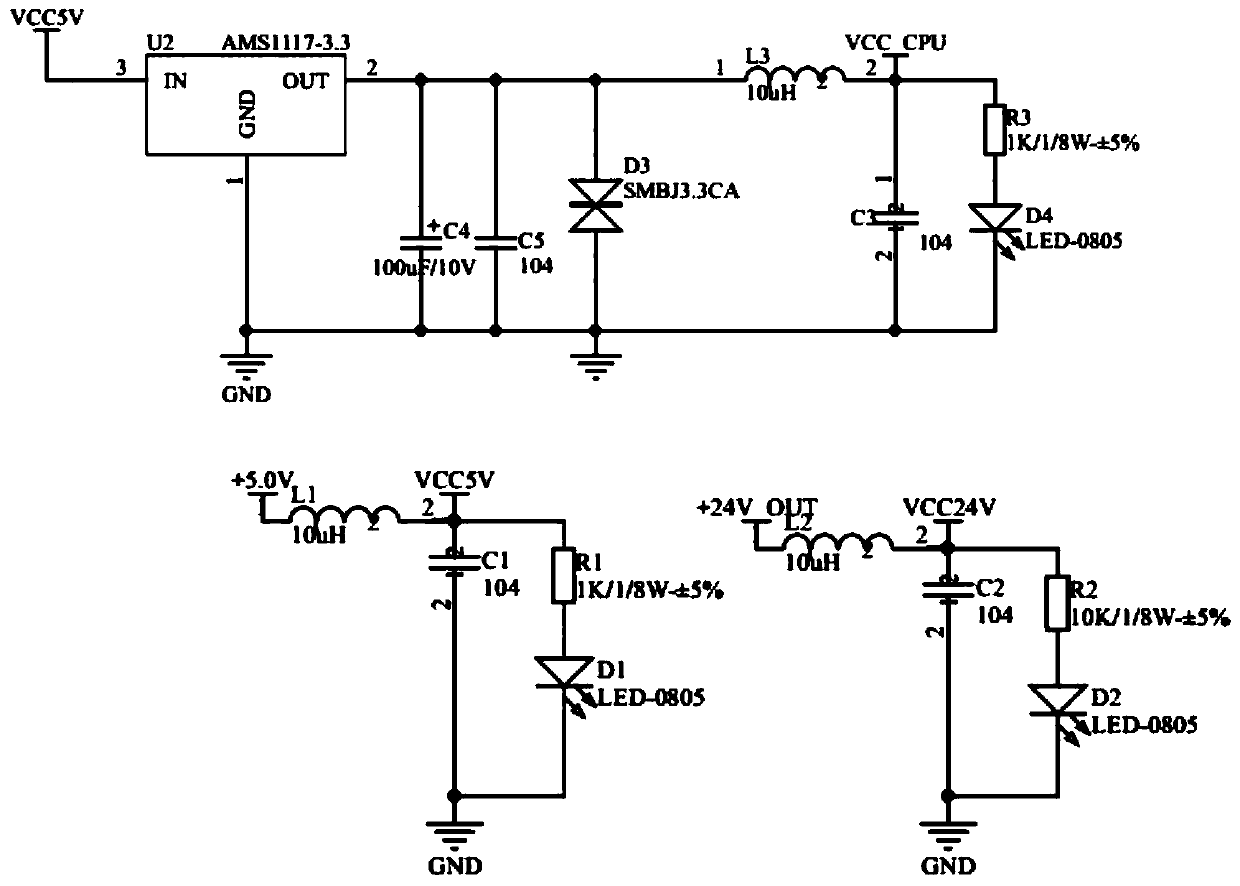

Control box and informatization printing process

Owner:中科数扬(青岛)智能科技有限公司

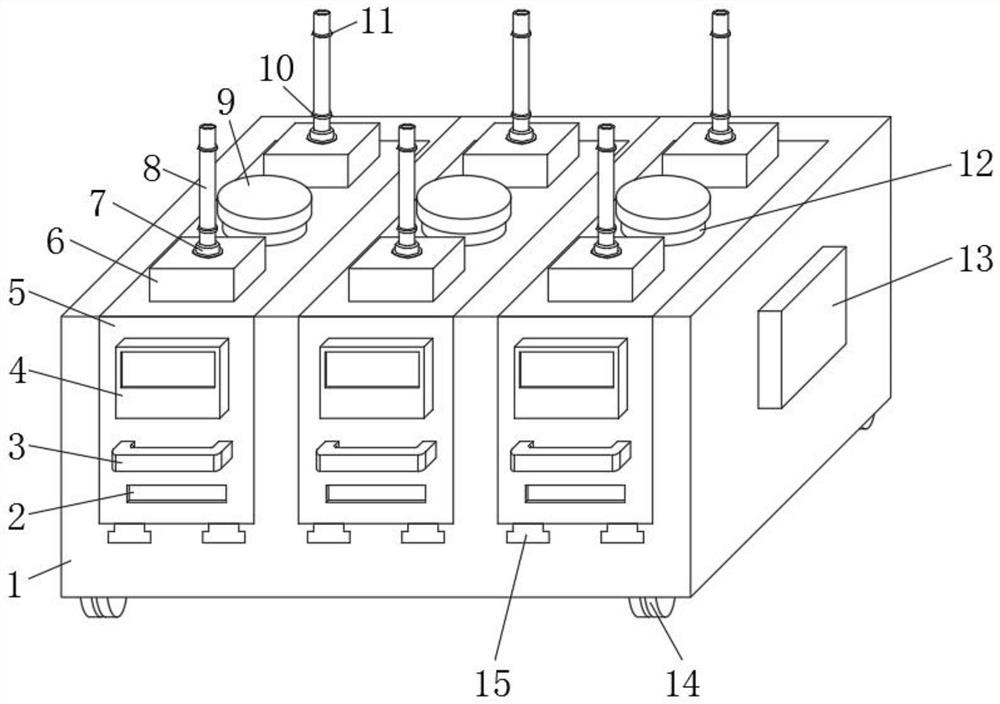

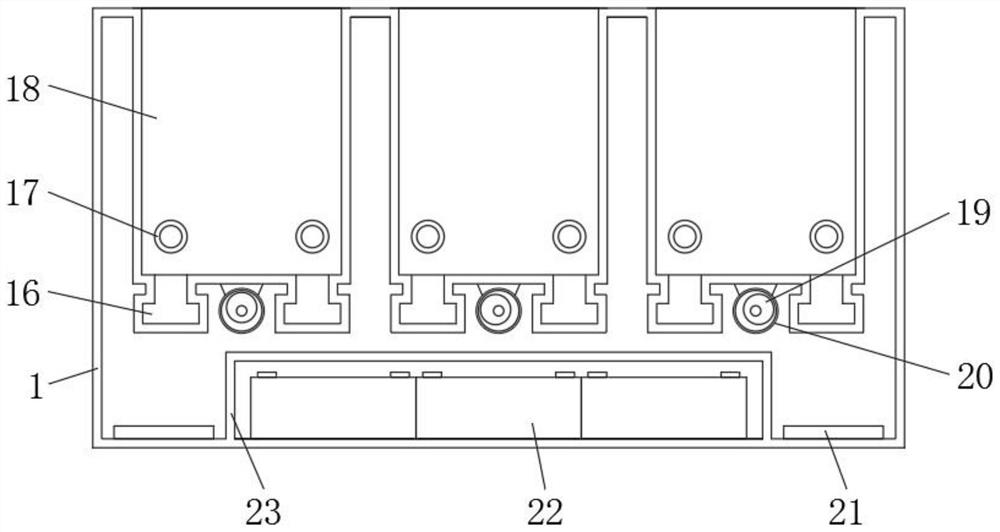

Continuous production device of carbon powder for printing machine

InactiveCN111550995AStir wellFast dryingDrying gas arrangementsDrying chambers/containersAgitatorPrinting press

The invention discloses a continuous production device of carbon powder for a printing machine. The continuous production device of the carbon powder for the printing machine structurally comprises amachine body, a feeding opening, a discharging opening, a stirrer and a conveyor, wherein the feeding opening is formed in the upper portion of the machine body, the discharging opening is formed in the front portion of the machine body, and the upper portion of the interior of the machine body is in sliding connection with the stirrer. According to the device, in the stirring process, air guns start to work, stop blocks around the air guns can surround and rotate, under the condition of rapid rotation, no gap exists around the air guns, objects to be treated such as wood chips cannot make contact with air openings of the air guns, the phenomenon of air opening blockage is avoided, at the moment, the air guns facing upwards can blow off to-be-treated objects attached to a stirring body anda rotating body through small holes in the front ends of the stop blocks, the air guns perpendicular to a connecting body can blow away the to-be-treated objects, gaps among the blown-away to-be-treated objects can be enlarged, and the drying speed of the to-be-treated objects can be increased through cooperation of wind power.

Owner:刘洋

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap