A jumping device for on-line cold ironing of a printing machine

A printing press, skipping technology, applied in printing presses, rotary presses, printing and other directions, can solve problems such as waste, and achieve the effect of protecting the environment, improving the utilization rate, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

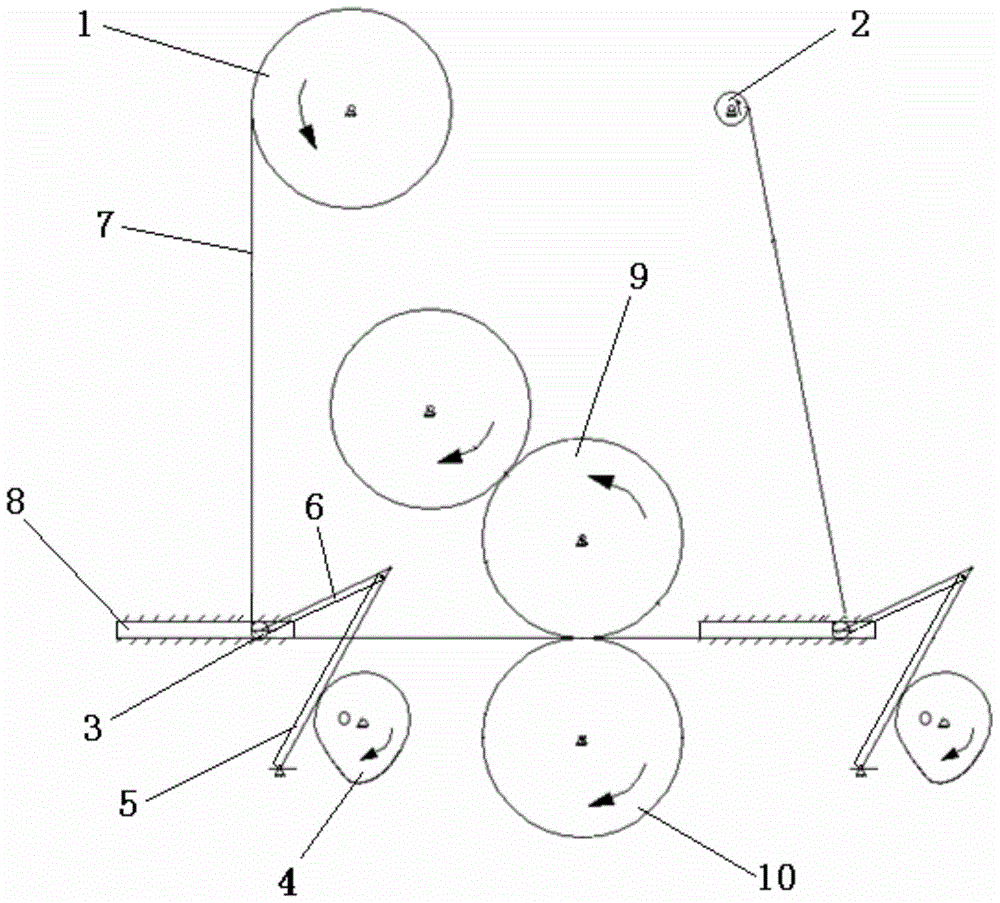

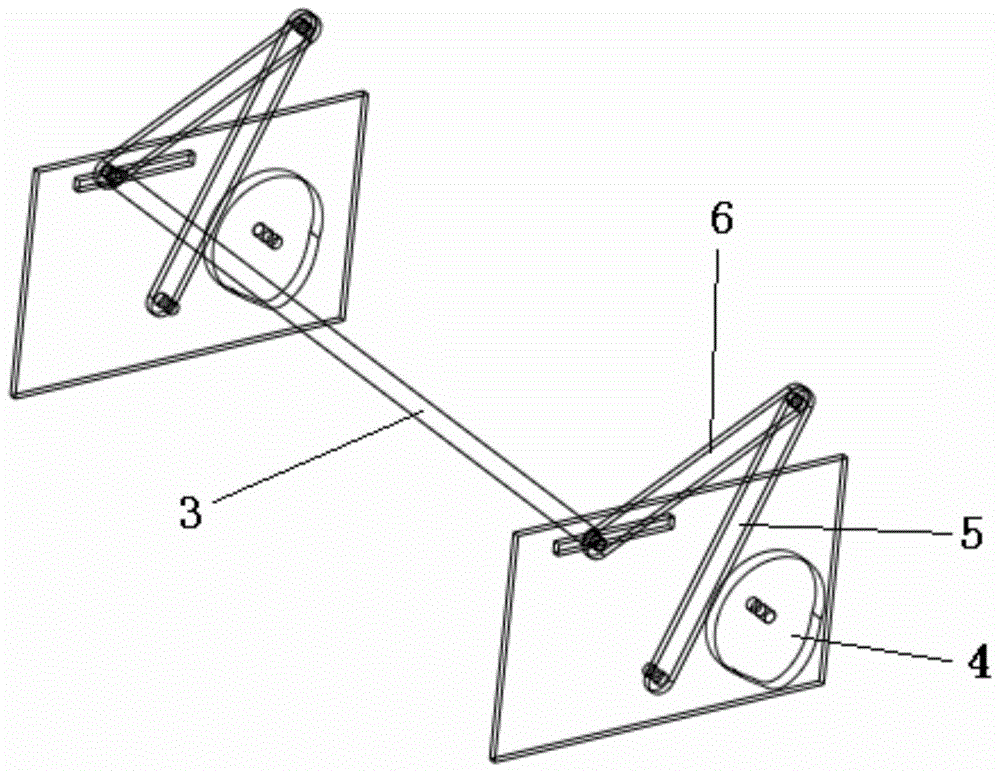

[0012] An embodiment of the present invention provides a skipping device for on-line cold ironing of a printing machine, comprising: an unwinding device, a winding device, two anilox rollers and four sets of driving mechanisms; wherein the unwinding device and the winding device are respectively It is used to put and collect electrified aluminum foil; one said anilox roller is respectively arranged on the path of anodized aluminum foil entering and leaving the printing unit; said anilox roller is arranged between the wall panels on both sides of the printing machine, and its two ends are respectively A set of driving mechanisms is connected, and the anilox roller can slide along the guide grooves on the wall panels on both si

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap