A high-efficiency ink printing machine

A printing machine, high-efficiency technology, applied in the direction of printing, printing devices, etc., can solve the problems of printing coil folds, adjust the tension, affect the printing quality, etc., and achieve the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

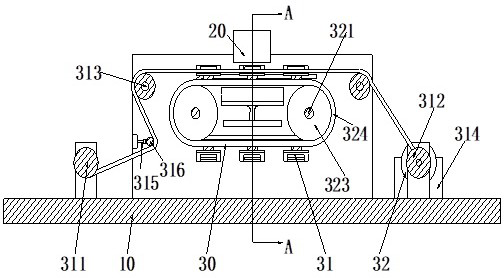

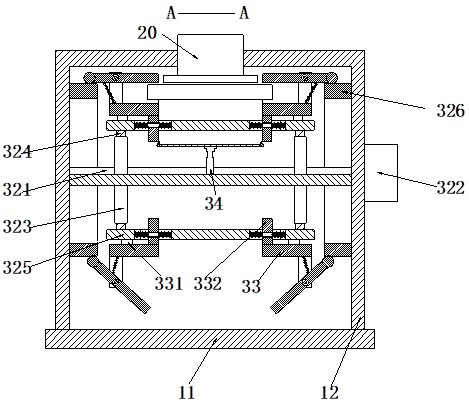

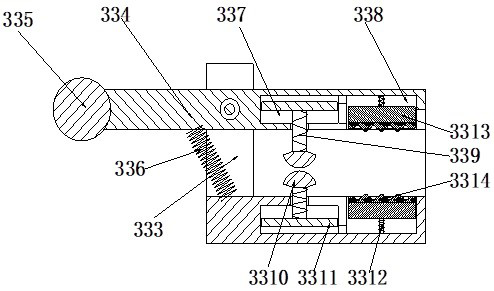

[0027] like Figure 1 to Figure 6 As shown, a high-efficiency ink printing machine includes a frame 10, a printing machine body 20 fixed on the middle part of the upper end of the frame 10, and a conveying tensioning device 30 arranged on the frame 10. The frame 10 includes a bottom plate 11 and The vertical plates 12 are arranged symmetrically on the left and right sides of the bottom plate 11 , and the conveying tensioning device 30 includes a conveying mechanism 31 disposed on the bottom plate 11 and a tensioning mechanism 32 disposed between the two vertical plates 12 .

[0028] The conveying mechanism 31 includes a winding roller 311 arranged at the front end of the bottom plate 11, a winding roller 312 installed at the rear end of the bottom plat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap