Apparatus for feeding foil of printing machine with tension

a technology of printing machine and foil, applied in printing presses, embossing decorations, printing, etc., can solve the problems of waste of processing material f, achieve the effect of preventing foil damage, high speed, and easy adjustment of tension applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

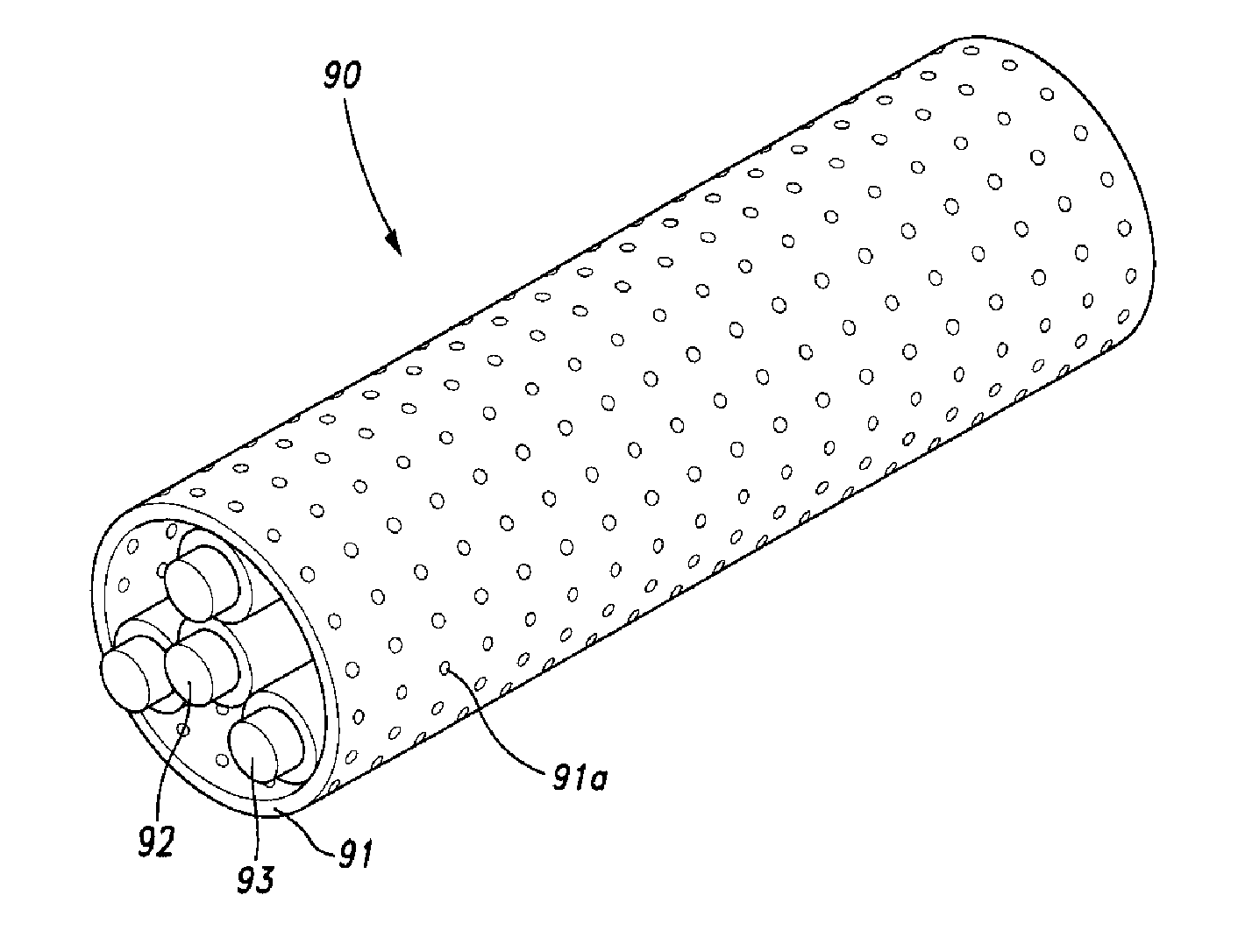

Image

Examples

Embodiment Construction

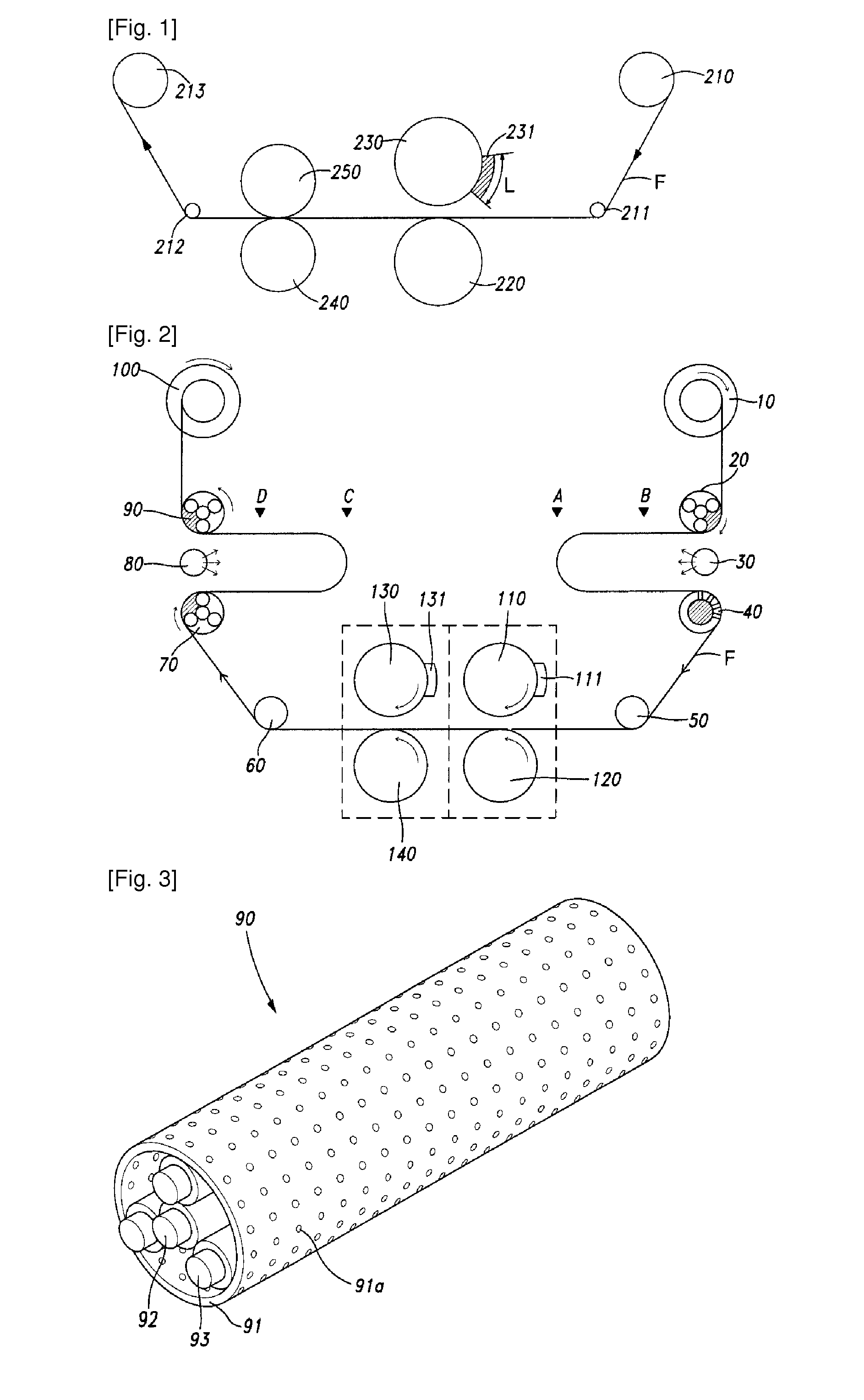

[0022]FIG. 2 is a schematic view illustrating a printing machine according to the present invention. As shown, a foil F wound in a storage reel 10 is unwound as a storage reel 10 is rotated. The unwound foil F moves to a blower 30 in accordance with guide of a tension adjustment shaft 20. The foil F, which has passed through the tension adjustment shaft 20, is blown by compressed air of the blower 30 at a given length. The foil, which has passed through the blower 30, passes through a suction shaft 40 and then reaches a printing part marked with a dotted line. In the printing part, a die 111 of an impression roller 110 performs printing while the impression roller 110 is rotated in a state that it is engaged with a lower roller 120. Feed rollers 130 and 140 at the rear of the printing part are rotated by being synchronized with the impression roller 110. A die 131 of the feed roller 130 has an arc greater than that of a die 111 of the impression roller 110, and moves the foil F without

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap