Control box and informatization printing process

A control box and process technology, applied in the field of electronics and information engineering, can solve the problems of unrealized intelligent production, printing machine stop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

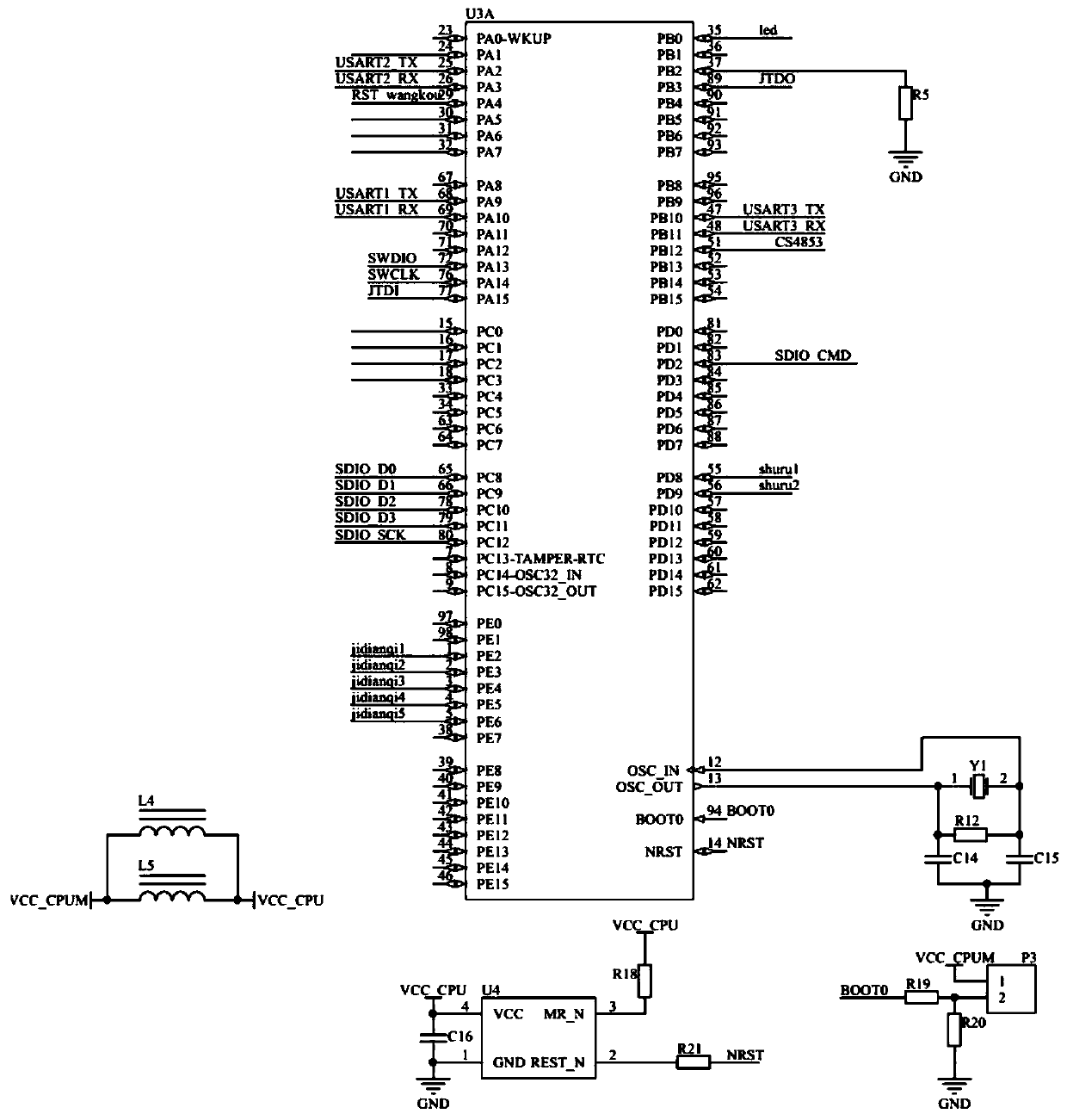

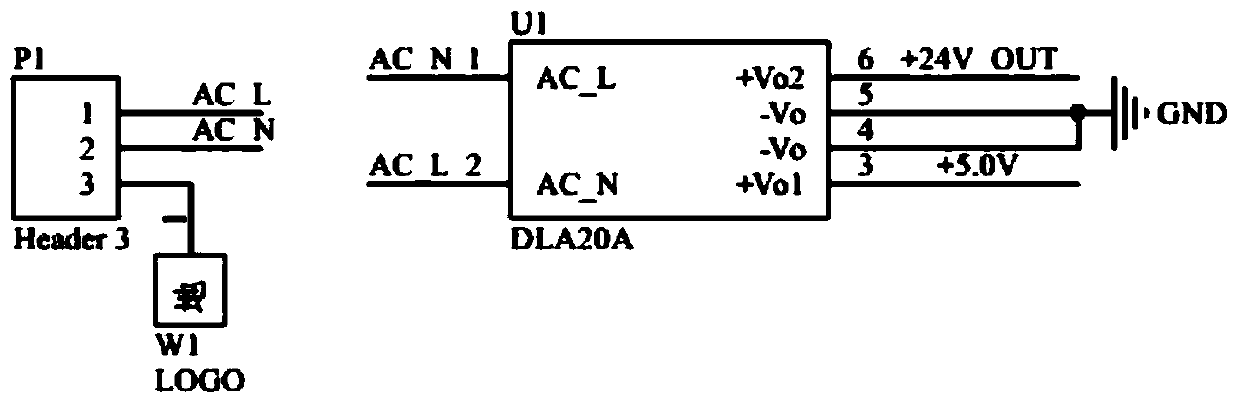

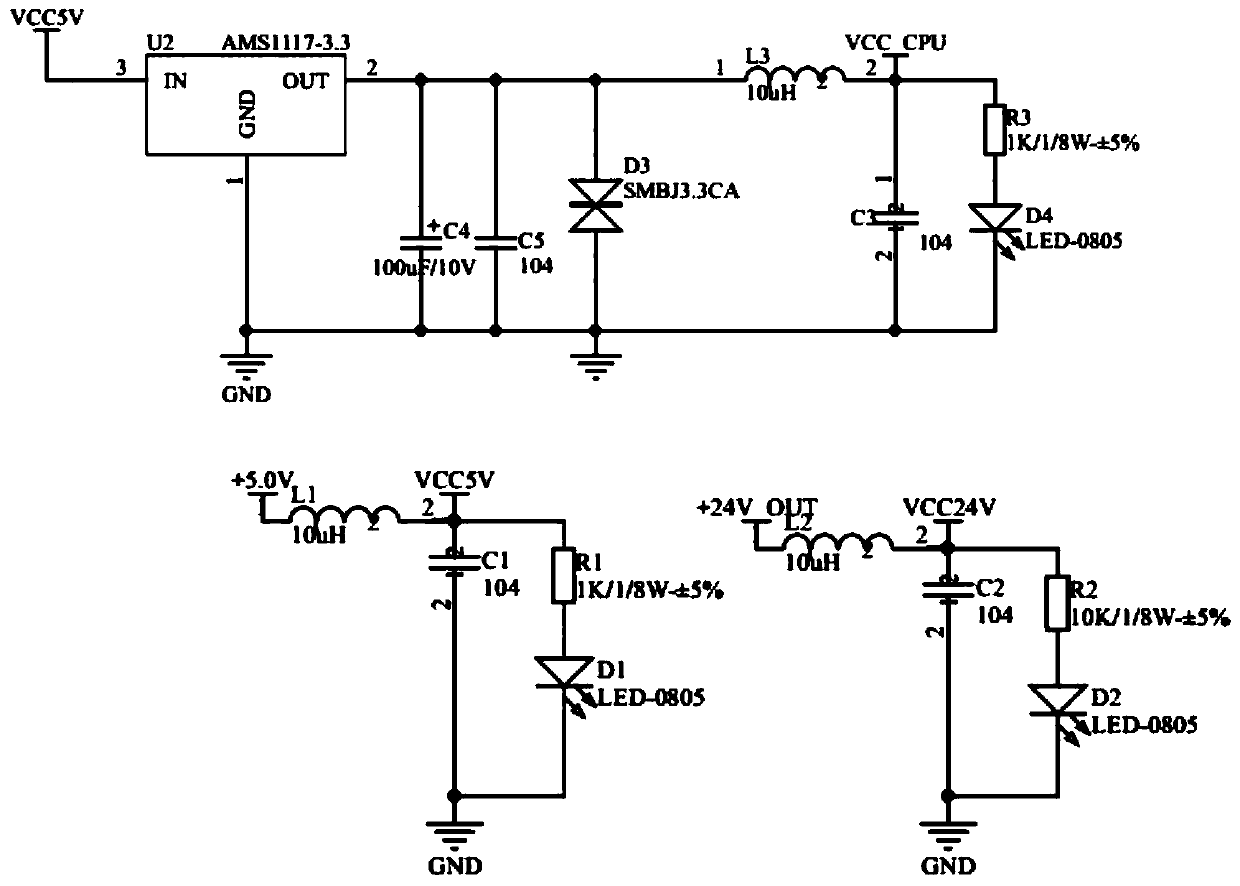

[0043] A control box, comprising: a casing, a circuit board is installed in the casing, and the circuit board includes: an MCU module, an AC-DC module, a power management module, a storage module, an Ethernet interface module, an RS232 interface module, an RS485 interface module, and a relay Interface module, digital interface module, 4-20MA interface module, 0-10V interface module, DI / DO interface, IIC interface and SIP interface.

[0044] AC-DC module, power management module, storage module, Ethernet interface module, RS232 interface module, RS485 interface module, relay interface module, digital interface module, 4-20MA interface module and 0-10V interface module are electrically connected to the MCU module , DI / DO interface, IIC interface and SIP interface are the interfaces that come with the MCU module.

[0045] In this embodiment, the circuit diagram of the MCU module is as follows figure 1 As shown, the circuit diagram of the AC-DC module is shown in figure 2 As s

Embodiment 2

[0047] An information printing process, including a printing machine, a control box and an upper platform, the printing machine includes: a sequentially connected upper paper area, paper separation area, C area, M area, Y area, K area, powder spraying area and lower paper area, the control box communicates with the upper platform, and also includes the electrical connection with the control box:

[0048] The output parameter monitoring module is used to calculate the output parameter of the printing machine;

[0049] Printing machine parameter monitoring module, used to monitor the state of the printing machine;

[0050] A sampling monitoring module for monitoring operations used for operations;

[0051] The process parameter monitoring module is used to monitor the process parameters of the printing machine and to guide the control;

[0052] The environmental parameter monitoring module is used to monitor the environmental parameters of the printing press for guidance and cont

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap