Spray device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

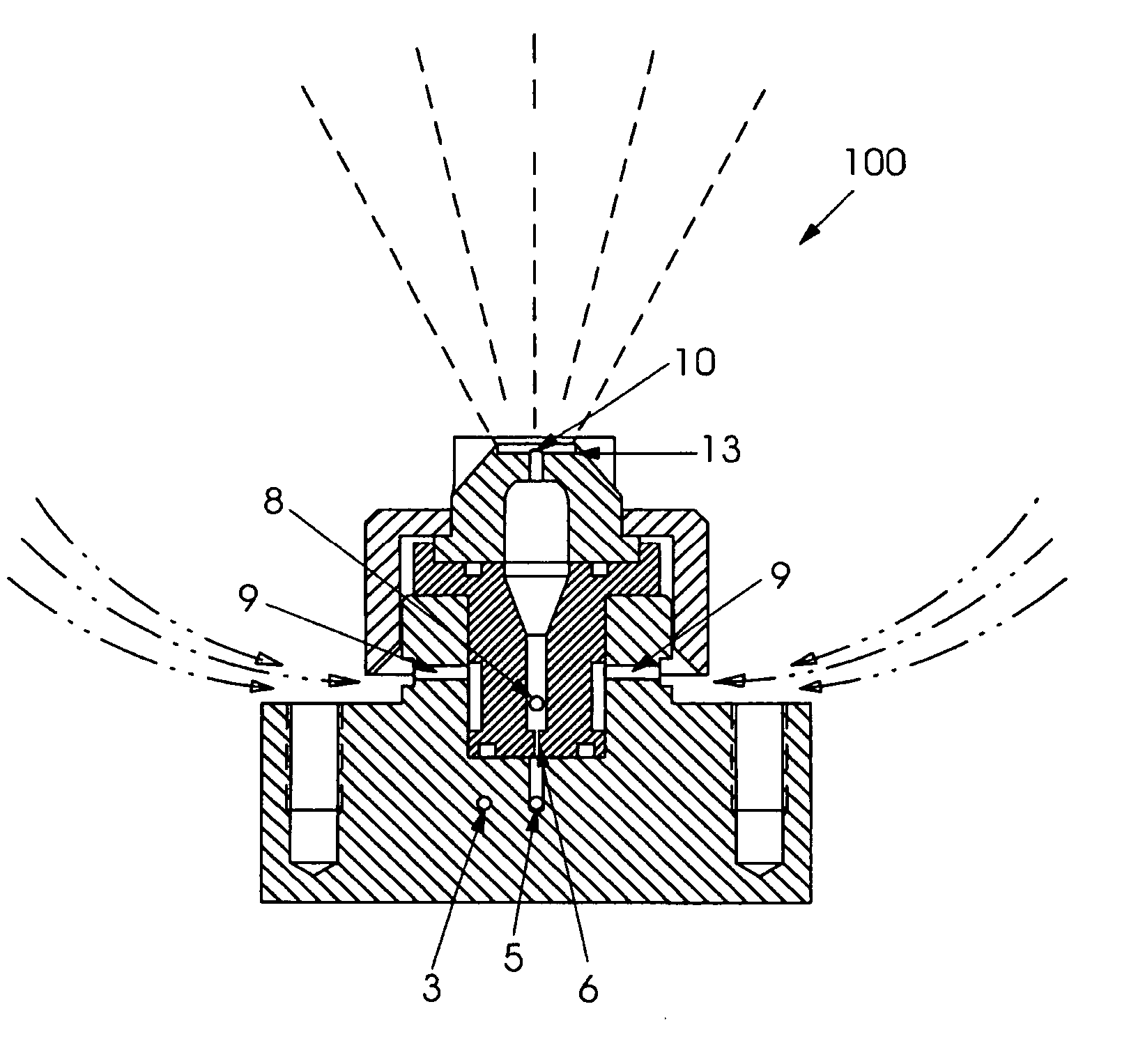

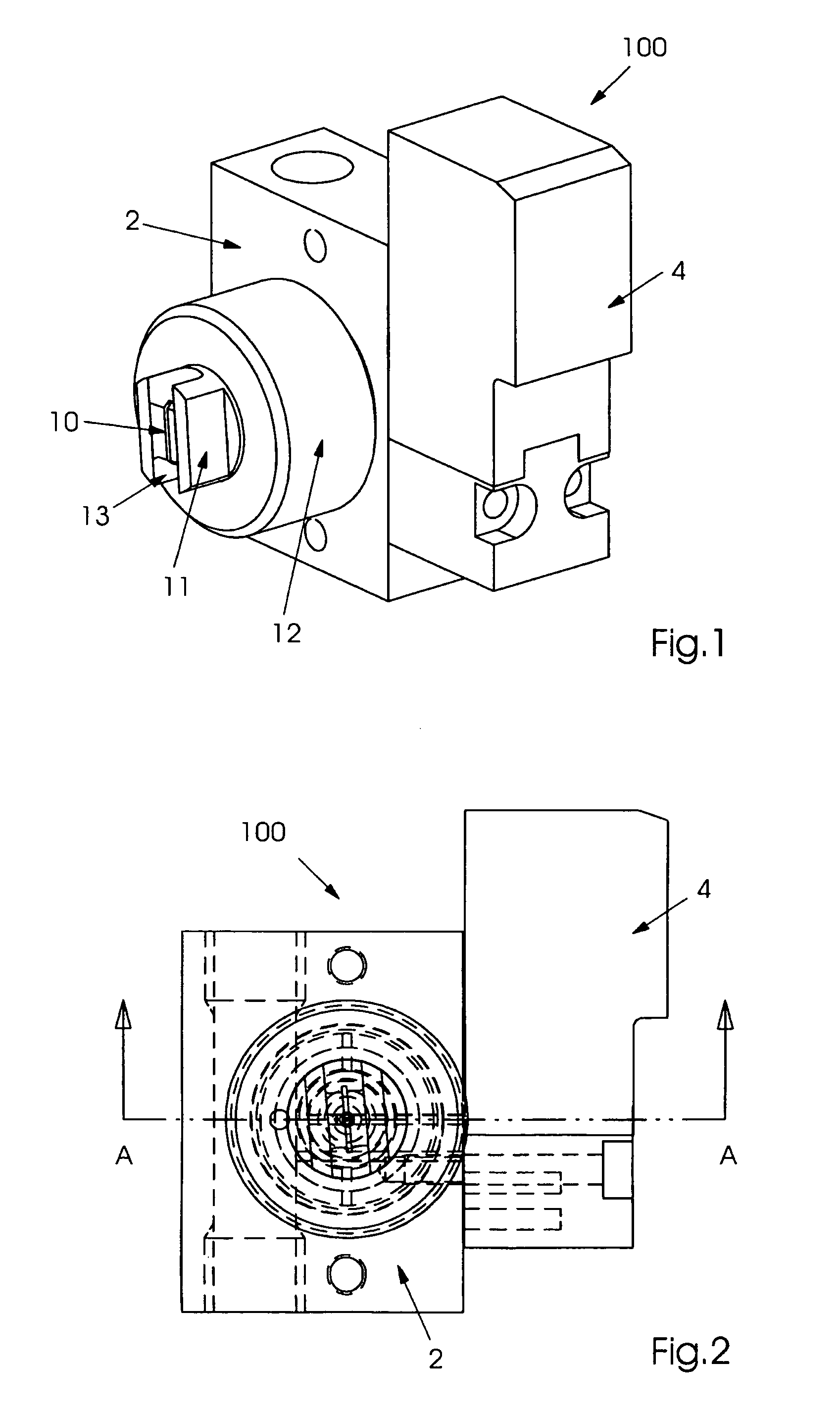

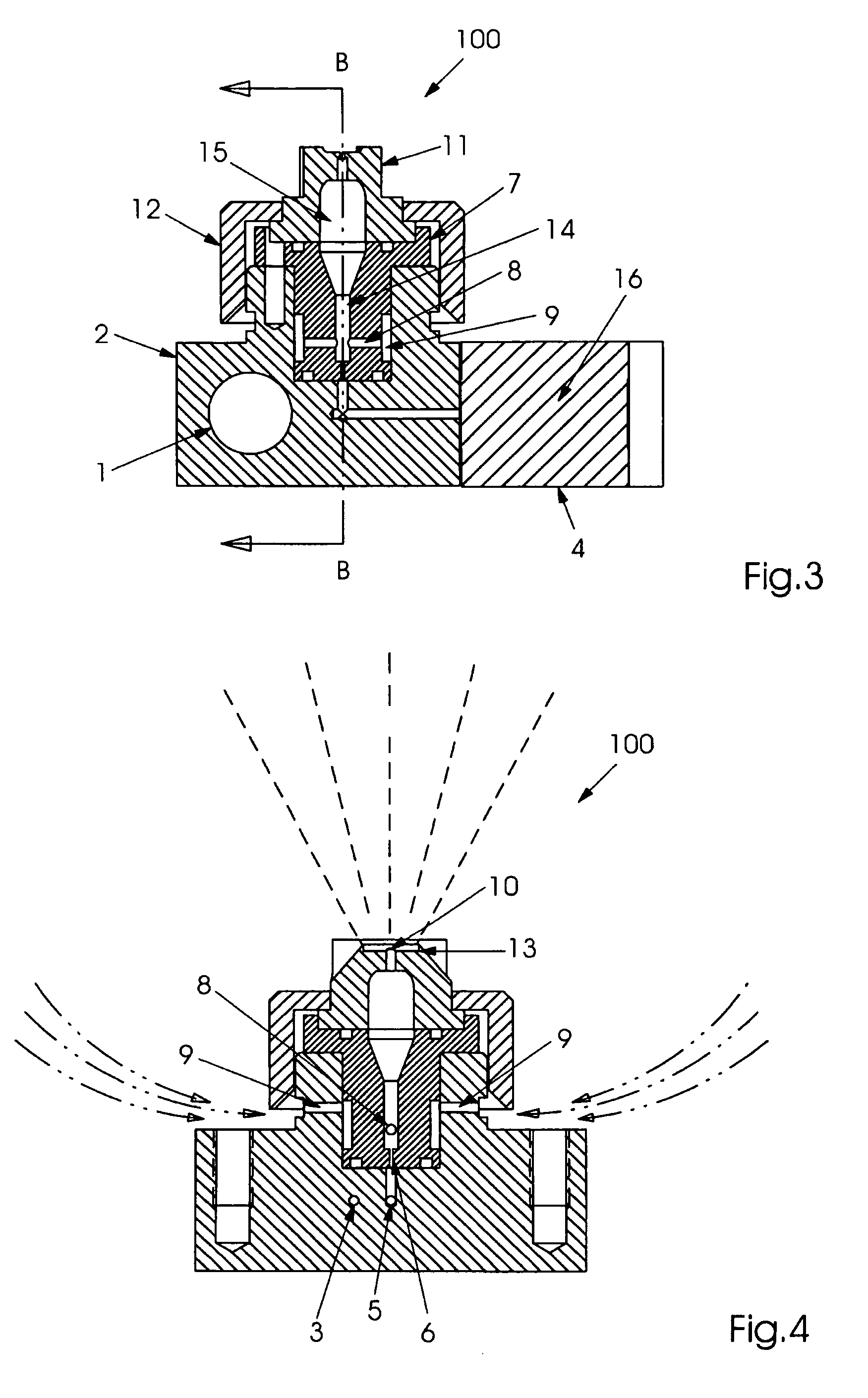

[0028]FIGS. 1 and 2 show an exemplary embodiment of a spray device 100 of the present invention. Screw cap 12 is threaded onto body member 2 and holds nozzle tip 11 in place. Exit orifice 10 is visible on the front on spray device 100 as is flat-bottom slot 13. Solenoid 4 is mounted to the side of body 2 for actuating a valve element 16 inside of solenoid 4, to repeatedly interrupt a flow of liquid through the spray device and cause pulsed spraying.

[0029] The paths of the liquid and gas through the spray device are visible in the sectional views of FIG. 3 (showing a sectional view through line A-A of FIG. 1) and in FIG. 4 (showing a sectional view through line B-B of FIG. 3). A liquid enters the body member 2 through liquid supply conduit 1. Where the spray device is used for dampening a plate cylinder on a printing press, the liquid is typically a fountain solution of water that includes additives to reduce its surface tension. In other applications of the spray device, the liquid ma

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap