Self-shearing packaging decoration printing machine

A printing machine and self-shearing technology, which is applied to printing machines, rotary printing machines, printing, etc., can solve the problems of different tightness, affecting printing quality, and shaking of substrates, so as to improve printing quality, protect normal operation, Avoid the effect of slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

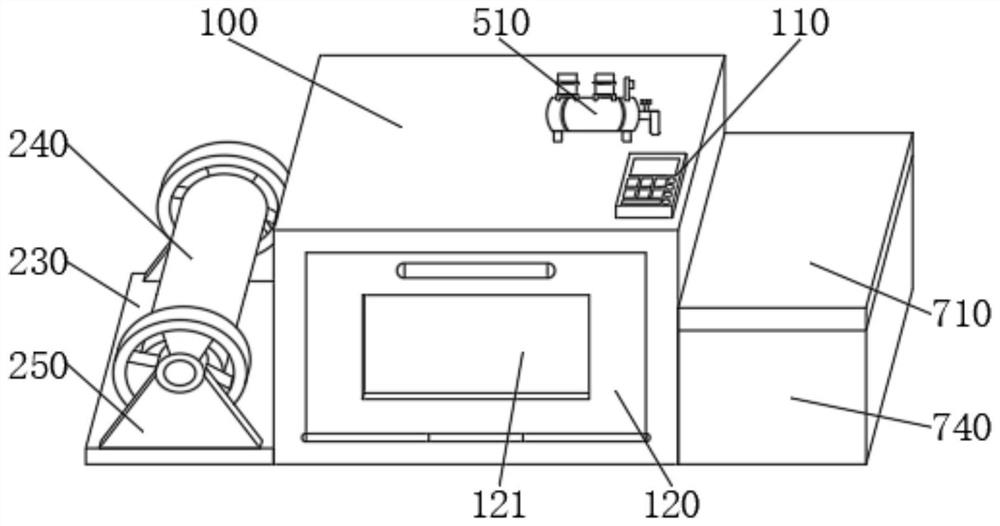

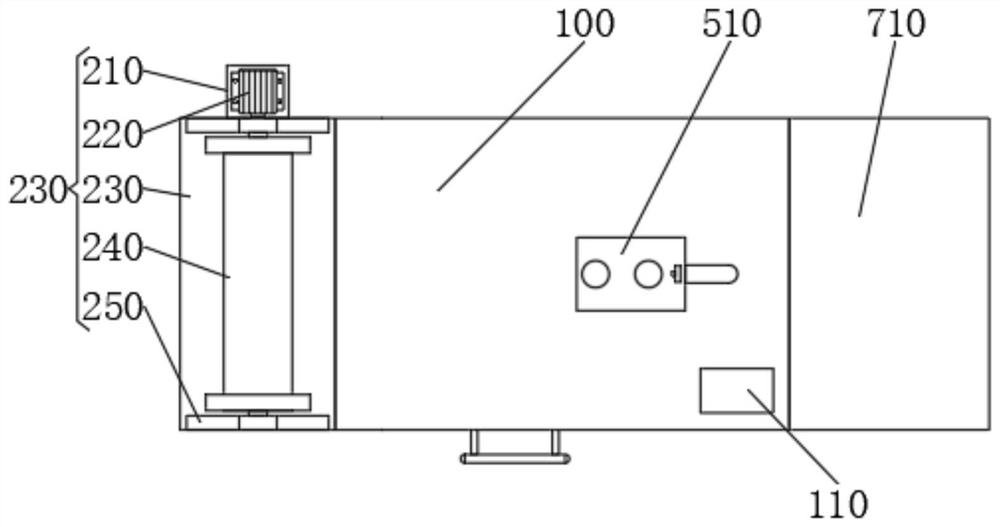

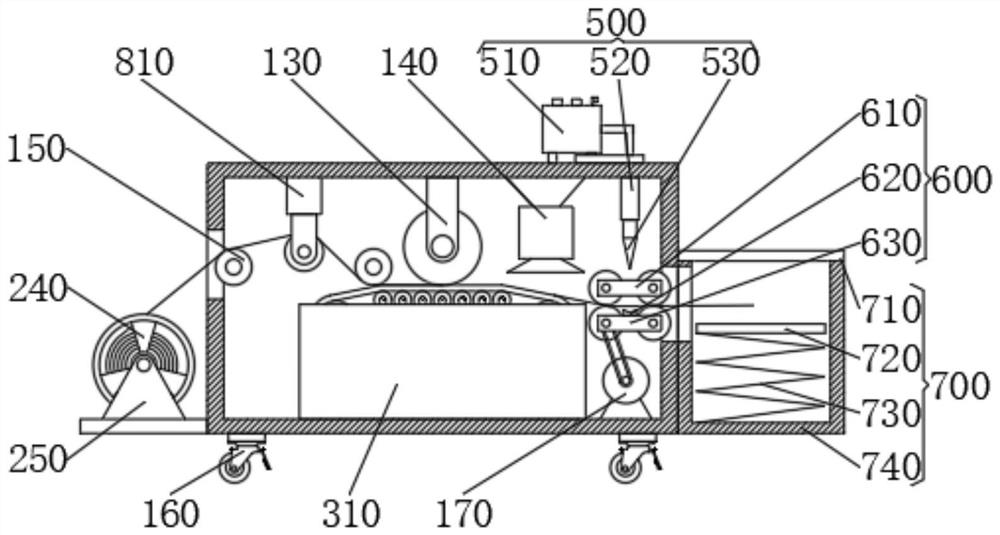

[0026] see Figure 1-3 and Figure 5-6, the present invention provides a technical solution: a drying device for textiles, including a main body 100, an unwinding mechanism 200, a supporting mechanism 300, a transmission mechanism 400, a shearing mechanism 500, a fixing mechanism 600, a collecting mechanism 700 and a tensioning mechanism 800, the unwinding mechanism 200 is fixedly connected to the lower side of the left side wall of the main body 100, the support mechanism 300 is fixedly connected to the middle of the inner cavity bottom of the main body 100, the transmission mechanism 400 is rotatably connected to the inner cavity of the supporting mechanism 300, and the shearing mechanism 500 runs through Fixedly connected to the top right side of the body 100, the fixing mechanism 600 is rotatably connected to the middle of the right side of the rear side wall of the body 100, the collection mechanism 700 is fixedly connected to the lower side of the right side wall of the bod

Embodiment 2

[0028] see figure 1 and Figure 3-4 , the present invention provides a technical solution: a drying device for textiles, including a main body 100, an unwinding mechanism 200, a supporting mechanism 300, a transmission mechanism 400, a shearing mechanism 500, a fixing mechanism 600, a collecting mechanism 700 and a tensioning mechanism 800, the unwinding mechanism 200 is fixedly connected to the lower side of the left side wall of the main body 100, the support mechanism 300 is fixedly connected to the middle of the inner cavity bottom of the main body 100, the transmission mechanism 400 is rotatably connected to the inner cavity of the supporting mechanism 300, and the shearing mechanism 500 runs through Fixedly connected to the top right side of the body 100, the fixing mechanism 600 is rotatably connected to the middle of the right side of the rear side wall of the body 100, the collection mechanism 700 is fixedly connected to the lower side of the right side wall of the body

Embodiment 3

[0030] see Figure 1-3 and Figure 5 , the present invention provides a technical solution: a drying device for textiles, including a main body 100, an unwinding mechanism 200, a supporting mechanism 300, a transmission mechanism 400, a shearing mechanism 500, a fixing mechanism 600, a collecting mechanism 700 and a tensioning mechanism 800, the unwinding mechanism 200 is fixedly connected to the lower side of the left side wall of the main body 100, the support mechanism 300 is fixedly connected to the middle of the inner cavity bottom of the main body 100, the transmission mechanism 400 is rotatably connected to the inner cavity of the supporting mechanism 300, and the shearing mechanism 500 runs through Fixedly connected to the top right side of the body 100, the fixing mechanism 600 is rotatably connected to the middle of the right side of the rear side wall of the body 100, the collection mechanism 700 is fixedly connected to the lower side of the right side wall of the body

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap