Laminating device for LCM and screen

A bonding device and screen technology, applied in packaging, transportation and packaging, unsealing of objects, etc., can solve the problems of low degree of automation, achieve high degree of automation, and improve the effect of bonding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

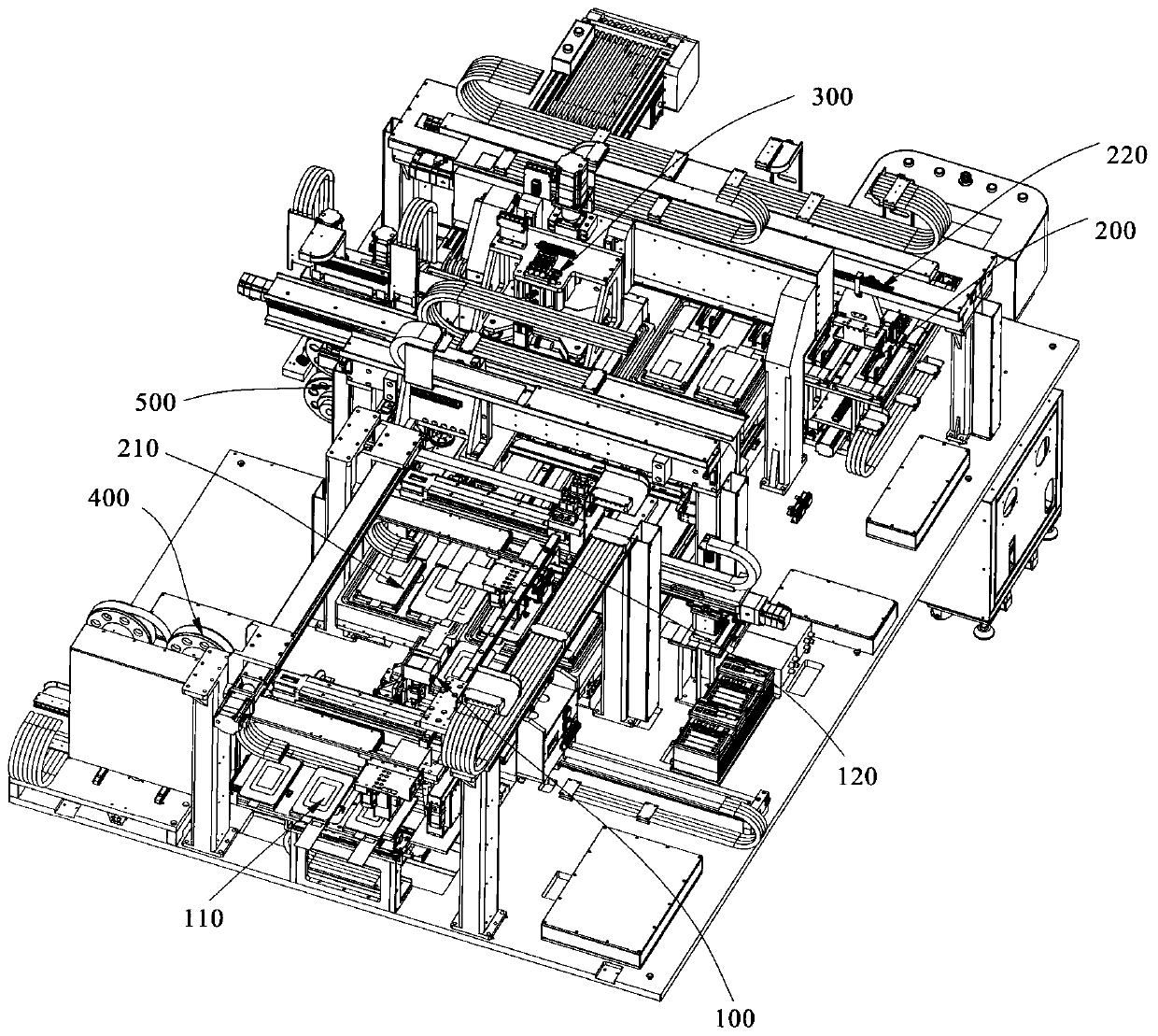

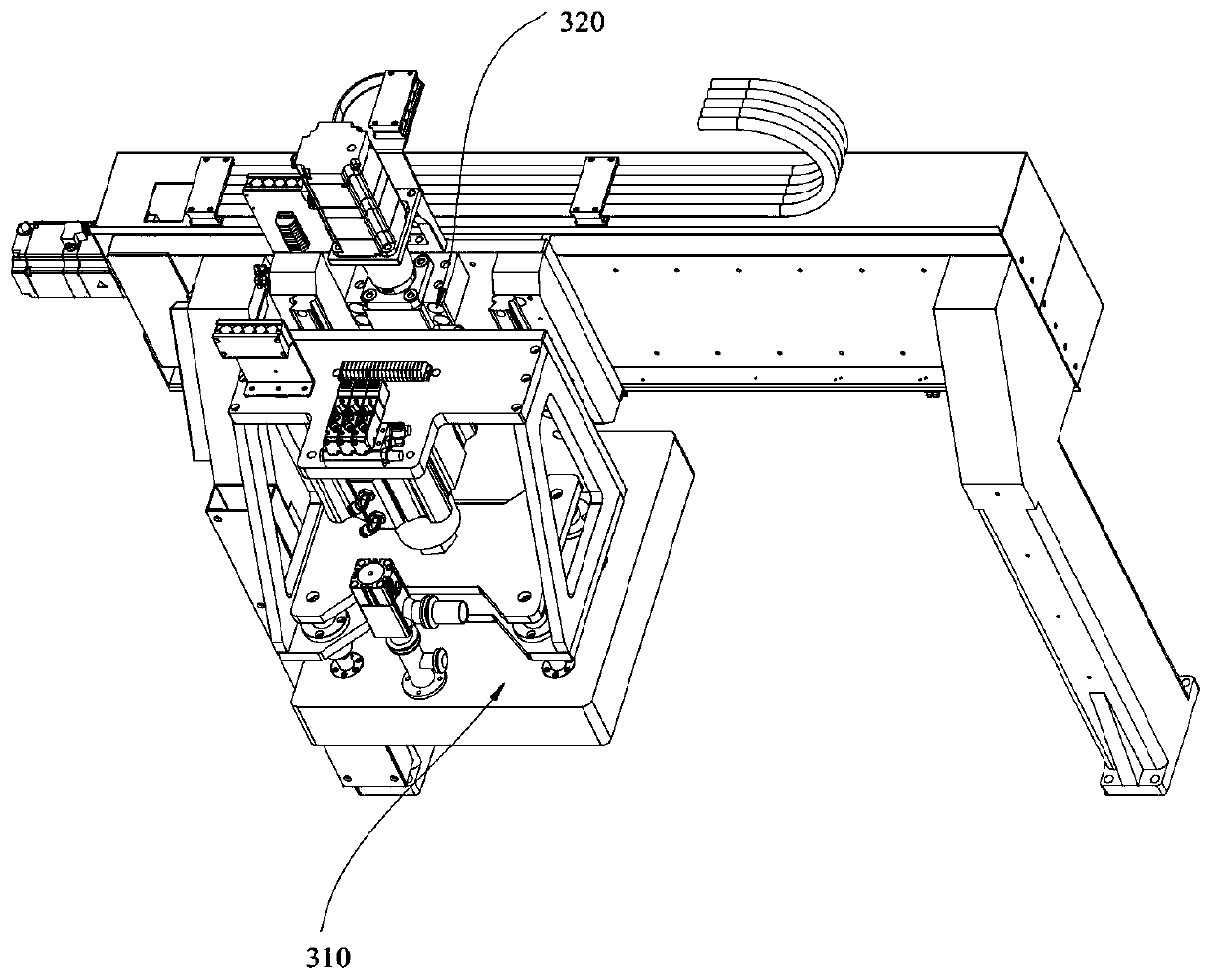

[0034] Such as Figure 1-9 The laminating device for an LCM and a screen shown includes a body, an LCM feeding mechanism 200 , a screen feeding mechanism 100 , an LCM tearing mechanism 500 , a screen tearing mechanism 400 and a pressing mechanism 300 . The LCM feeding mechanism 200, the screen feeding mechanism 100, the LCM tearing film mechanism 500, the screen tearing film mechanism 400 and the pressing mechanism 300 are all installed on the body, and the first tearing film station and the second tearing film station are arranged on the body. Station, alignment station, pressing station.

[0035] Specifically, the LCM loading mechanism 200 includes an LCM carrier 210 and an LCM carrier 210 conveying component. The LCM carrier 210 conveying component is used to convey the LCM carrier 210. The above-mentioned alignment station and pressing station are loc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap