One-step forming method for online hot stamping and concave-convex die cutting of web gravure printing

A gravure printing, web-based technology, applied in printing, printing devices, etc., can solve the problems of unstable web force, long processing cycle, speed mismatch, etc., to achieve smooth completion of equipment operations, reduction of raw material costs, accurate The effect of increasing the degree of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

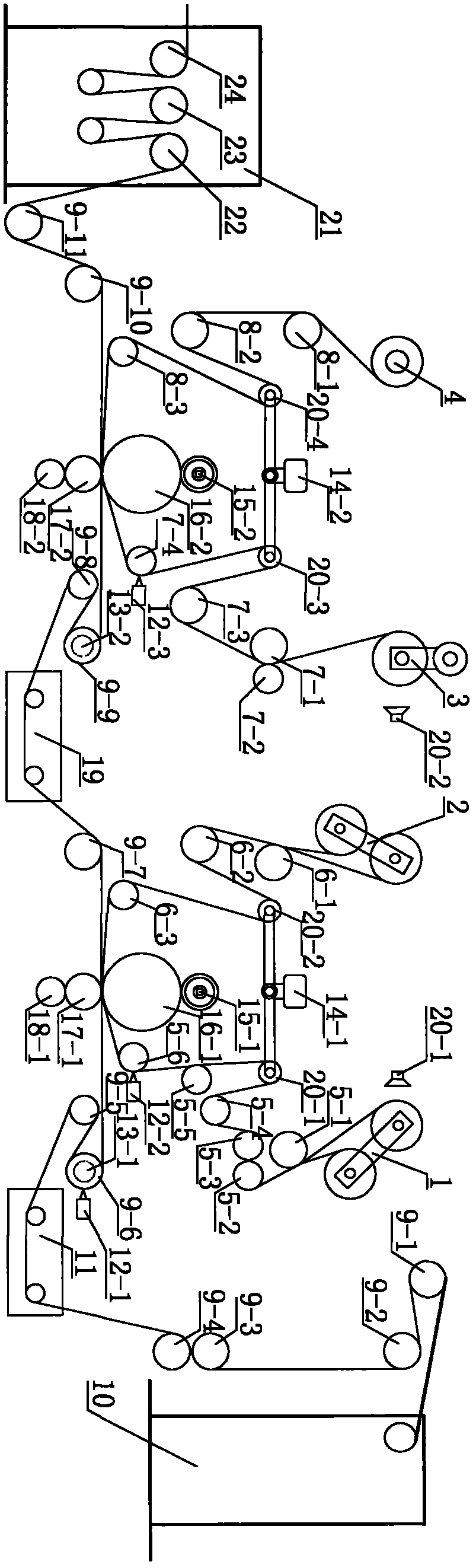

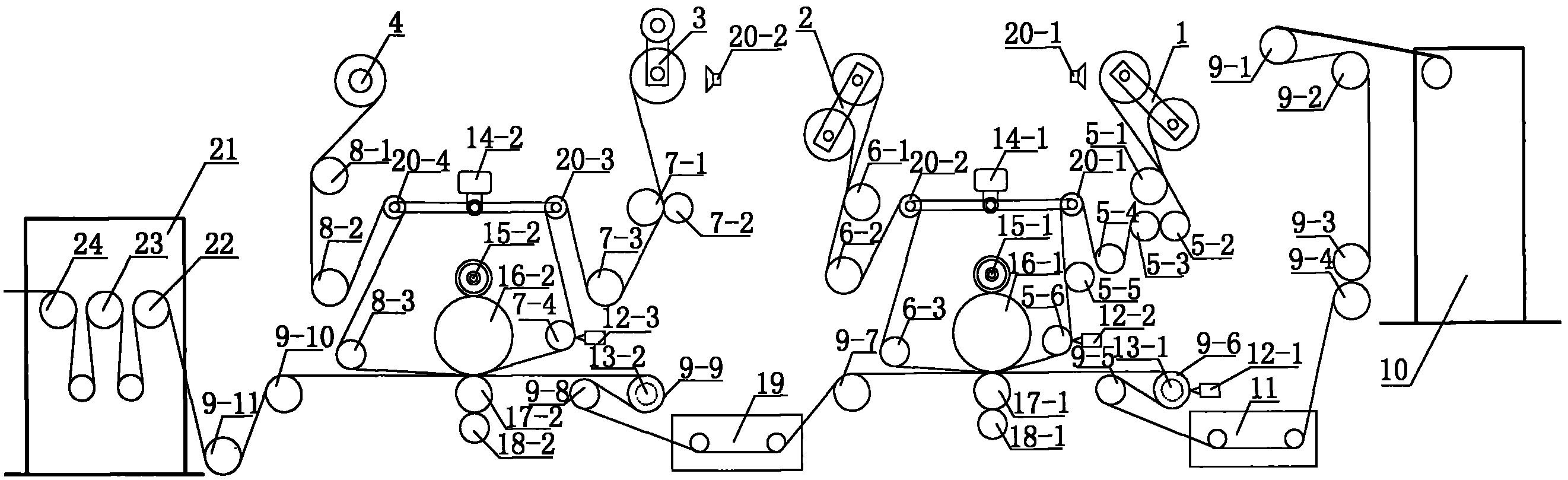

[0013] Such as figure 1 As shown, the web gravure printing online bronzing concave-convex die-cutting one-time forming equipment includes a printing machine 10 , a primary connecting device 11 , a primary bronzing device, a secondary connecting device 19 , a secondary bronzing device, and a processing device 21 .

[0014] The first-level bronzing device includes a first-level feeding device 1, a first-level receiving device 2, and a first-level feeding roller 5-1, 5-2, 5-3, 5-4, 5-4, 5-5, 5- 6. Regulating motor 14-1, serial moving rollers 20-1, 20-2, pressure stabilizing roller 15-1, bronzing roller 16-1, pressure roller 17-1, supporting roller 18-1, primary receiving roller 6 -1, 6-2, 6-3, line cursor tracker 12-1, 12-2, encoder 13-1, alarm system 20-1.

[0015] The secondary bronzing device includes secondary discharging device 3, secondary receiving device 4, secondary discharging rollers 7-1, 7-2, 7-3, 7-4, adjusting motor 14-2, and serial rollers 20 -3, 20-4, pressure stab

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap