Super-hydrophobic conformal coating, and preparation method and application method thereof

A super-hydrophobic and coating technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., to achieve the effects of improving comprehensive performance, good film-forming performance, and controllable film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In this embodiment, the superhydrophobic nano-SiO through alkyl modification 2 The preparation method is as follows:

[0054] Use hexadimethylsilane to treat ordinary nano-SiO 2 Modified by hexadimethylsilazane (HMDS) on SiO 2 A hydrolysis reaction occurs on the surface, and the siloxane group (-O-Si(CH 3 ) 3 ) to replace the surface hydroxyl group (-OH), the specific preparation process is: first nano-SiO 2 placed in N 2 In the atmosphere, pre-activate at a temperature of 390°C to 400°C for 60 minutes, then pass in HMDS liquid at 70-75°C, and after 50 minutes of reaction, use N 2 Purge the reaction product to obtain superhydrophobic nano-SiO with a WCA of 162°-165° 2 Powder.

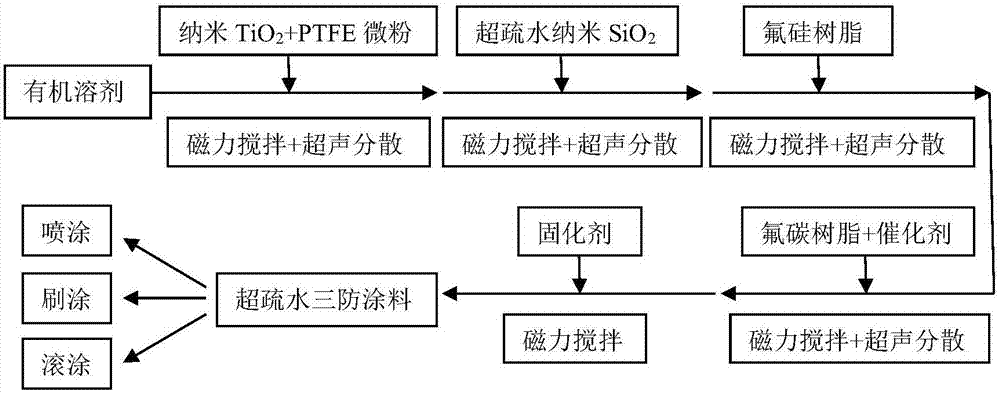

[0055] The preparation method of superhydrophobic three anti-coatings in the present embodiment (as figure 1 ) specifically includes the following steps, wherein the distribution ratio of each group is as shown in the following table 1:

[0056] Table 1: The ratio of each component of the s

Embodiment 2

[0081] In this embodiment, the superhydrophobic nano-SiO through alkyl modification 2 The preparation method is as follows:

[0082] Use hexadimethylsilane to treat ordinary nano-SiO 2 Modified by hexadimethylsilazane (HMDS) on SiO 2 A hydrolysis reaction occurs on the surface, and the siloxane group (-O-Si(CH 3 ) 3 ) to replace the surface hydroxyl group (-OH), the specific preparation process is: first nano-SiO 2 placed in N 2 In the atmosphere, pre-activate at a temperature of 350°C to 360°C for 55 minutes, then pass in HMDS liquid at 60°C to 70°C, and after 45 minutes of reaction, use N 2 Purge the reaction product to obtain superhydrophobic nano-SiO with a WCA of 160°-163° 2 Powder.

[0083] The preparation method of superhydrophobic three anti-coatings in the present embodiment (as figure 1 ) specifically includes the following steps, wherein the distribution ratio of each group is as shown in the following table 4:

[0084] Table 4: The distribution ratio of each

Embodiment 3

[0096] In this embodiment, the superhydrophobic nano-SiO through alkyl modification 2 The preparation method is as follows:

[0097] Use hexadimethylsilane to treat ordinary nano-SiO 2 Modified by hexadimethylsilazane (HMDS) on SiO 2 A hydrolysis reaction occurs on the surface, and the siloxane group (-O-Si(CH 3 ) 3 ) to replace the surface hydroxyl group (-OH), the specific preparation process is: first nano-SiO 2 placed in N 2 In the atmosphere, pre-activate at 300°C to 310°C for 30 minutes, then pass in HMDS liquid at 50°C to 55°C, after 30 minutes of reaction, use N 2 Purge the reaction product to obtain superhydrophobic nano-SiO with a WCA of 160°-163° 2 Powder.

[0098] The preparation method of superhydrophobic three anti-coatings in the present embodiment (as figure 1 ) specifically includes the following steps, wherein the distribution ratio of each group is as shown in the following table 5:

[0099] Table 5: The distribution ratio of each component of the supe

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface dry time | aaaaa | aaaaa |

| Hard work time | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap