Compressor system

a compressor system and compressor technology, applied in the direction of machines/engines, couplings, liquid fuel engines, etc., can solve the problems of hindering an increase in adversely affecting etc., to improve the rotor dynamics increase the rotation speed of the rotary sha

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011]Hereinafter, an embodiment for carrying out the compressor system according to the present disclosure will be described with reference to the attached drawings. However, the present disclosure is not limited to this embodiment only.

[0012](Compressor System)

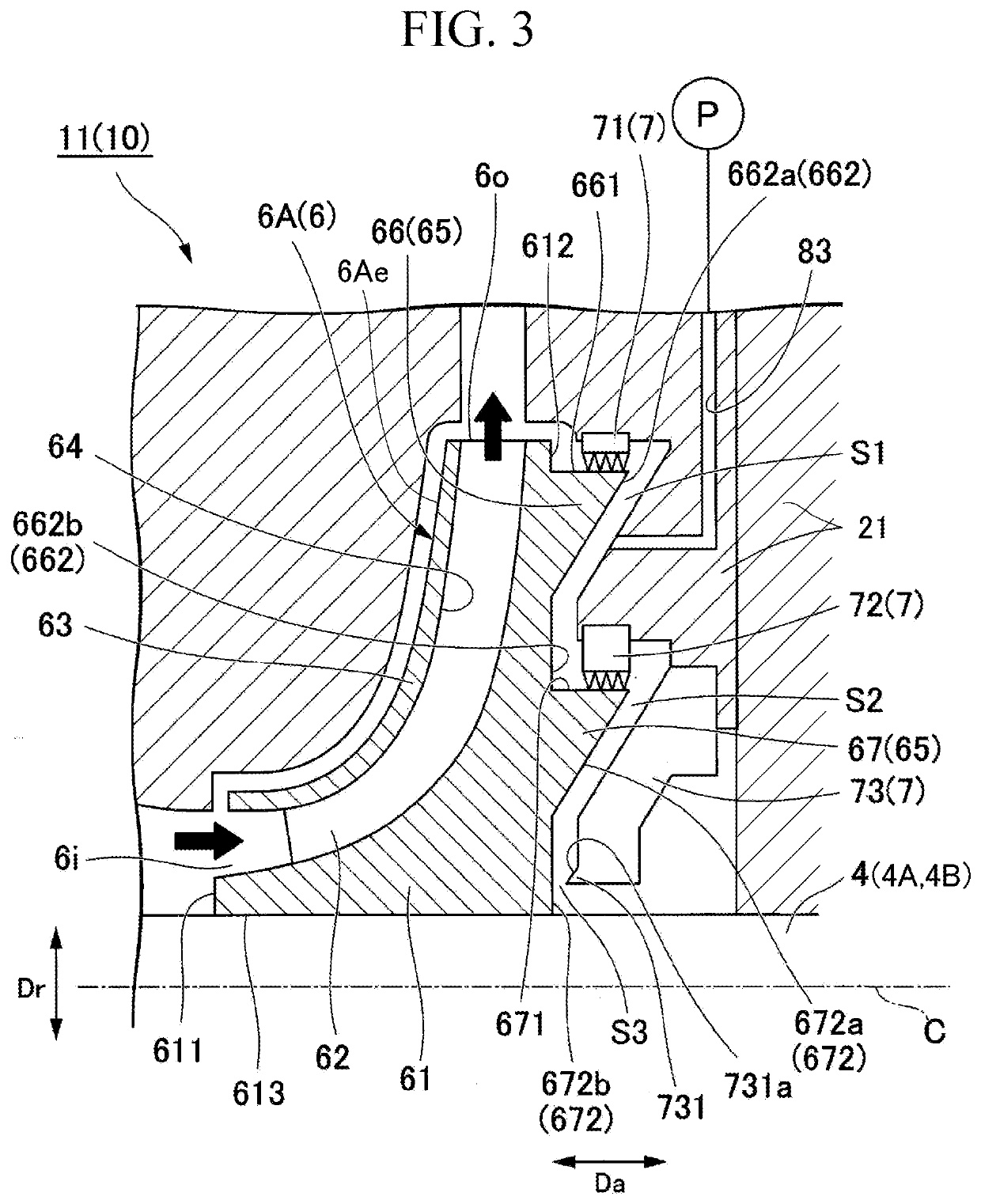

[0013]Hereinafter, the compressor system according to the present embodiment will be described with reference to FIGS. 1 to 3.

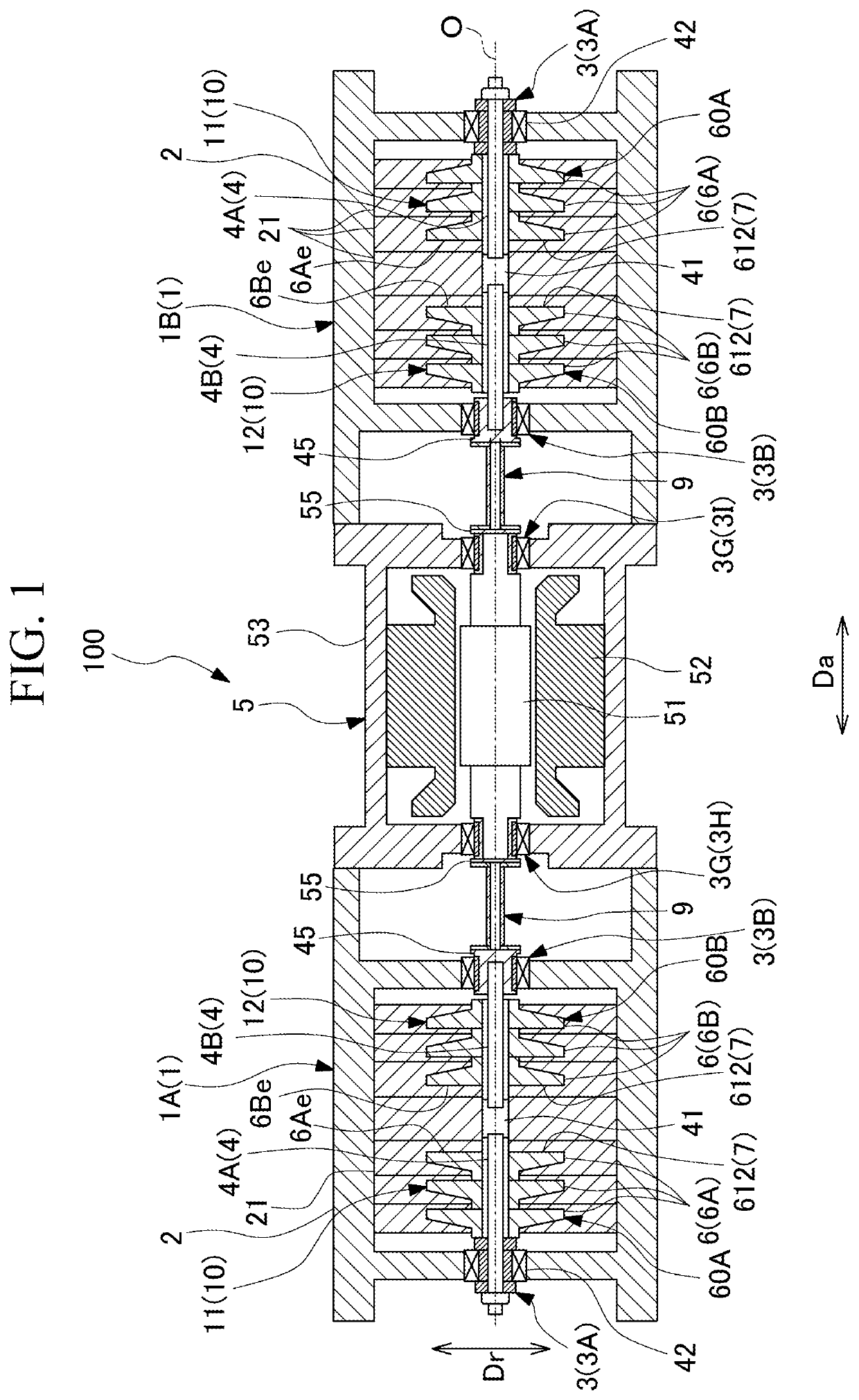

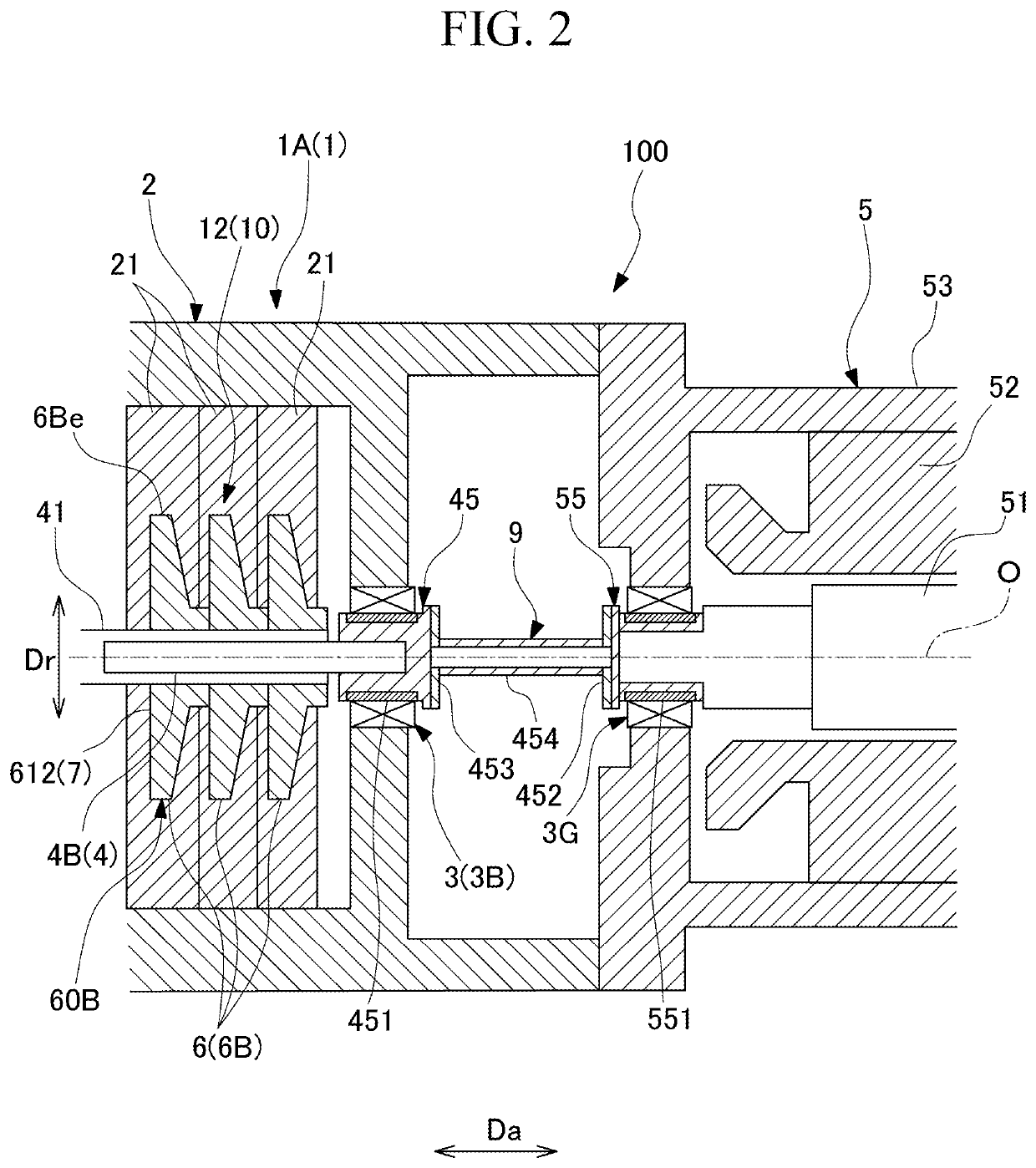

[0014]As illustrated in FIG. 1, the compressor system 100 includes a compressor 1, a motor 5, and a coupling shaft 9. In the present embodiment, the compressor 1 is disposed on both sides of the motor 5 with the motor 5 interposed therebetween. The compressor 1 includes a low-pressure side first compressor 1A disposed on a first side (left side with respect to the motor 5 in FIG. 1) in an axial direction Da described below with the motor 5 interposed between, and a high-pressure side second compressor 1B disposed on a second side (right side with respect to the motor 5 in FIG. 2) in the axial direction D

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap