High-temperature-resisting knuckle bearing for actuator

A kind of joint bearing, high temperature resistance technology, applied in the field of joint bearing, can solve the problem of overheating adhesion between the shaft core and the rod end bushing, and achieve the effect of avoiding high temperature adhesion, ensuring the force strength and improving the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and examples.

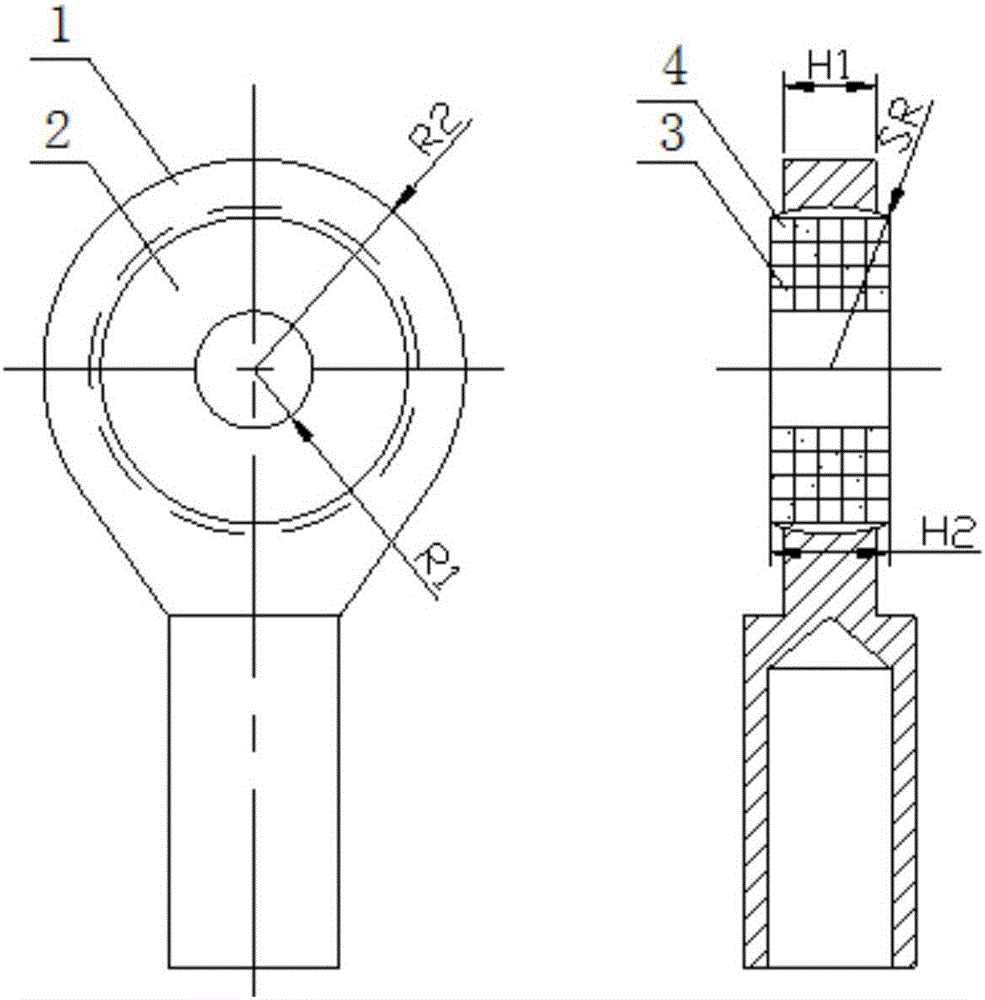

[0017] as attached figure 1 and 2 As shown, the present invention provides a high temperature resistant spherical plain bearing for an actuator, the spherical plain bearing is composed of a rod end bushing 1 and a shaft core 2, and the shaft core is made of a reticular alloy skeleton 3 and ceramic powder through a high temperature sintering process As a result, the shaft core is embedded in the process channel of the arc-shaped bottom surface of the rod end bushing 1 to form a joint bearing as a whole.

[0018] The mesh alloy skeleton 3 is formed by welding high-temperature alloy wires of different diameters or by 3D printing. The space grid of the mesh alloy skeleton 3 adopts tetrahedron or hexahedron; the ceramic powder is hafnium carbide HfC, zirconium carbide ZrC or tantalum carbide TaC , the ceramic powder and the mesh alloy skeleton are uniformly and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap