Gas extinguishing agent container valve

A gas fire extinguishing agent and container valve technology, applied in valve details, safety valves, balance valves, etc., can solve the problems of not being able to replace the pressure gauge in time and affecting the normal spraying of the gas fire extinguishing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

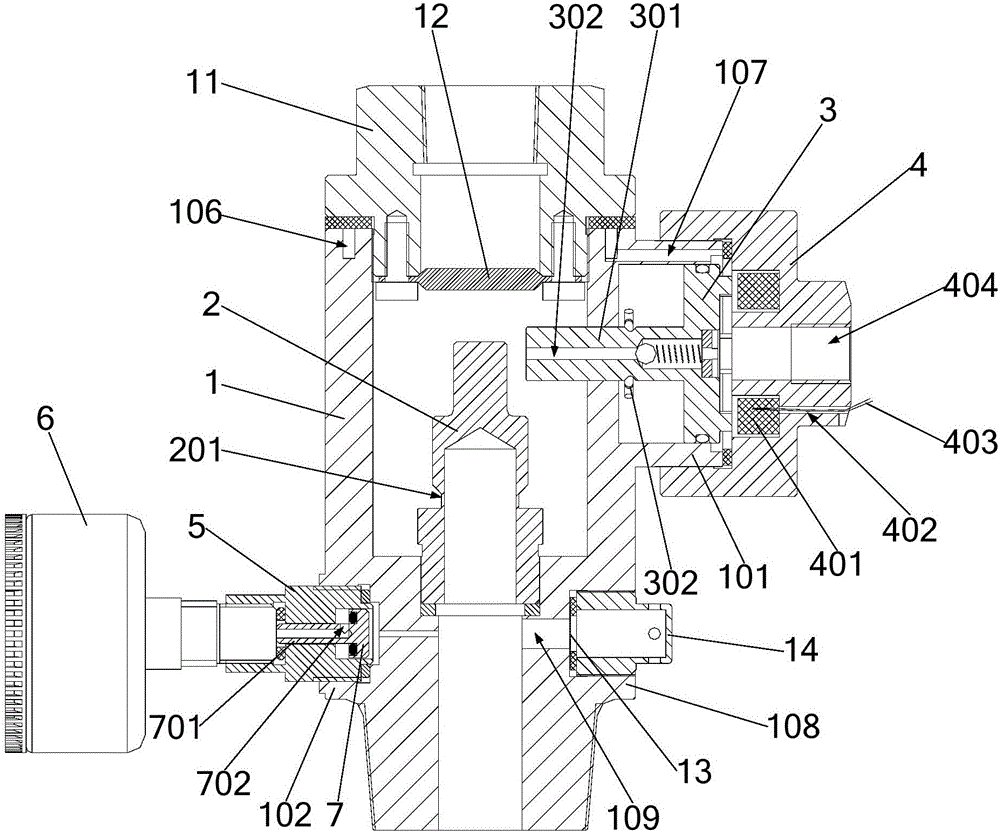

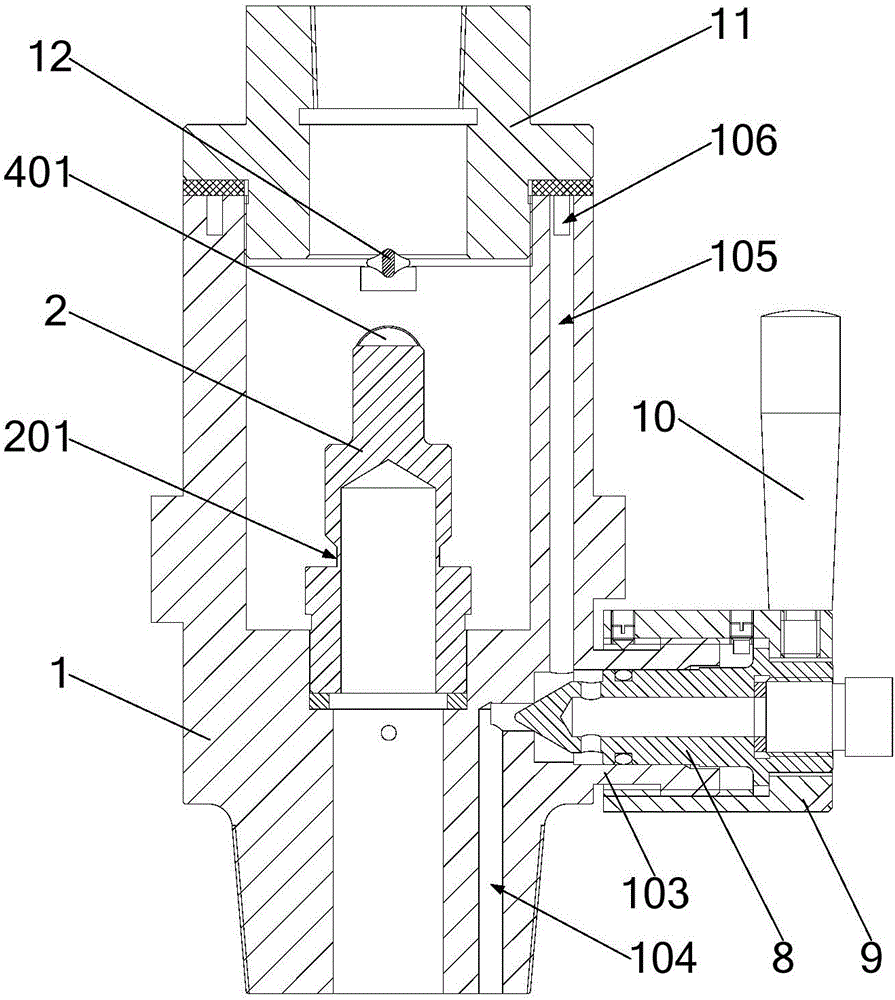

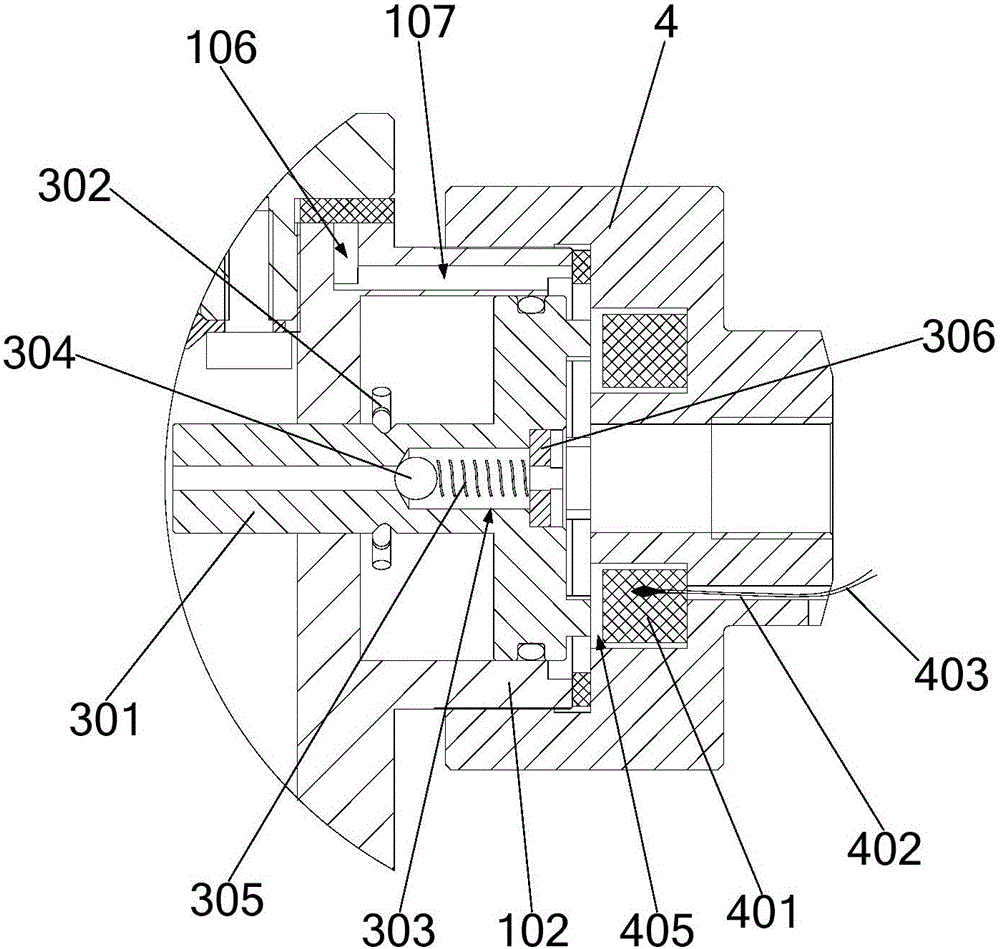

[0034] Such as figure 1 with figure 2 As shown, the embodiment of the present invention provides a gas fire extinguishing agent container valve, including a valve body 1, the valve body 1 is hollow, the upper port of the valve body 1 communicates with the gas collector, and the lower port of the valve body 1 Connected with the fire extinguishing agent cylinder, it also includes: an inner sealing cap 2, a starting interface 101, a pressure cap 4 and a pressure gauge seat 6; the inner sealing cap 2 is arranged in the valve body 1 and is isolated from the Between the upper port and the lower port, the inner sealing cap 2 is barrel-shaped, its open end is connected to the inside of the valve body 1, and its blind end extends toward the upper port of the valve body 1; the starting interface 101 is set on the outer wall of the valve body 1, and the bottom

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap