Valve

a valve and valve body technology, applied in the field of valves, can solve the problems of compromising the sterility of the valve, affecting the integrity of the second seal, and difficult to meet acceptable standards, so as to easy to separate the first seal, and reduce the risk of loose particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

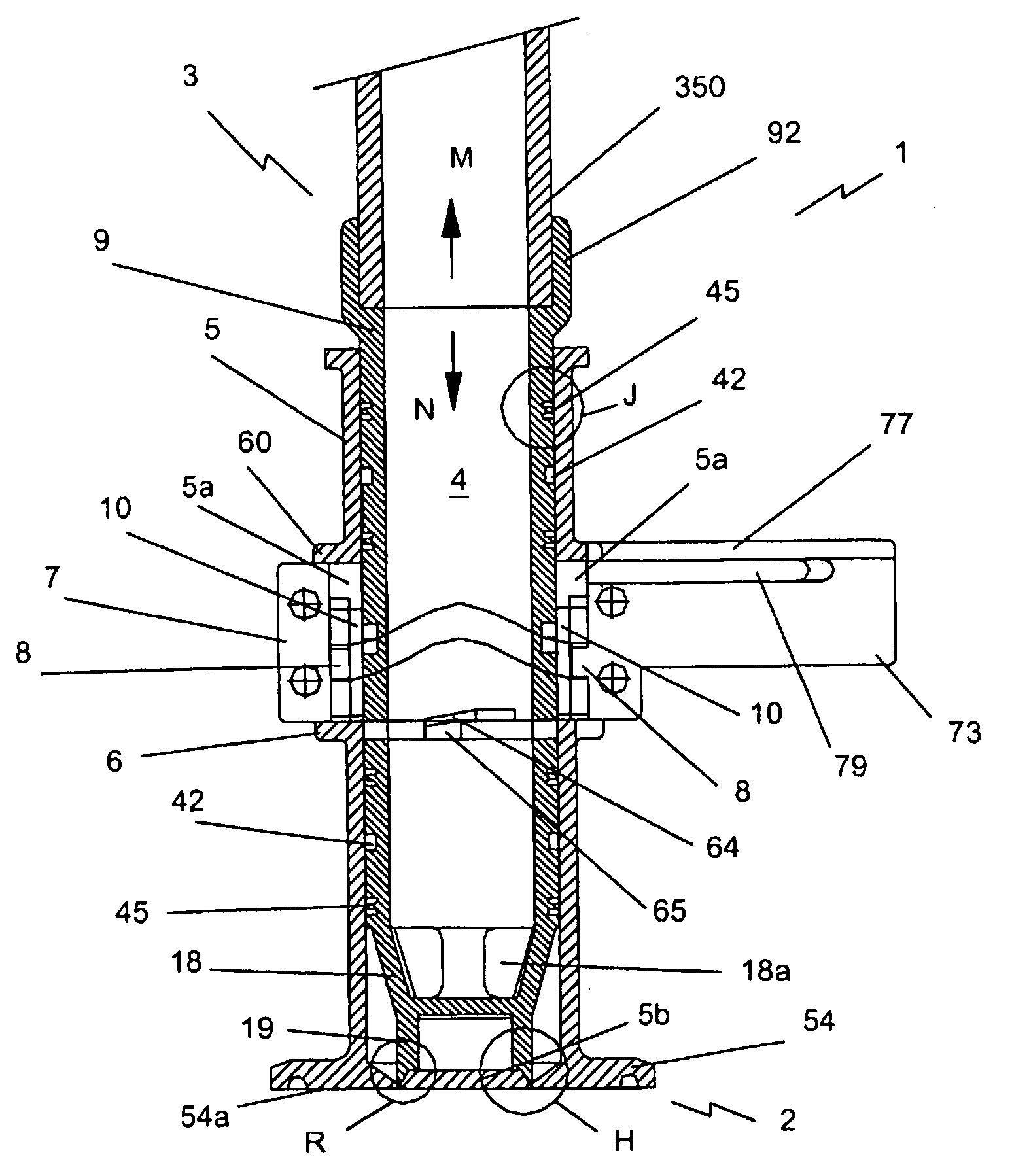

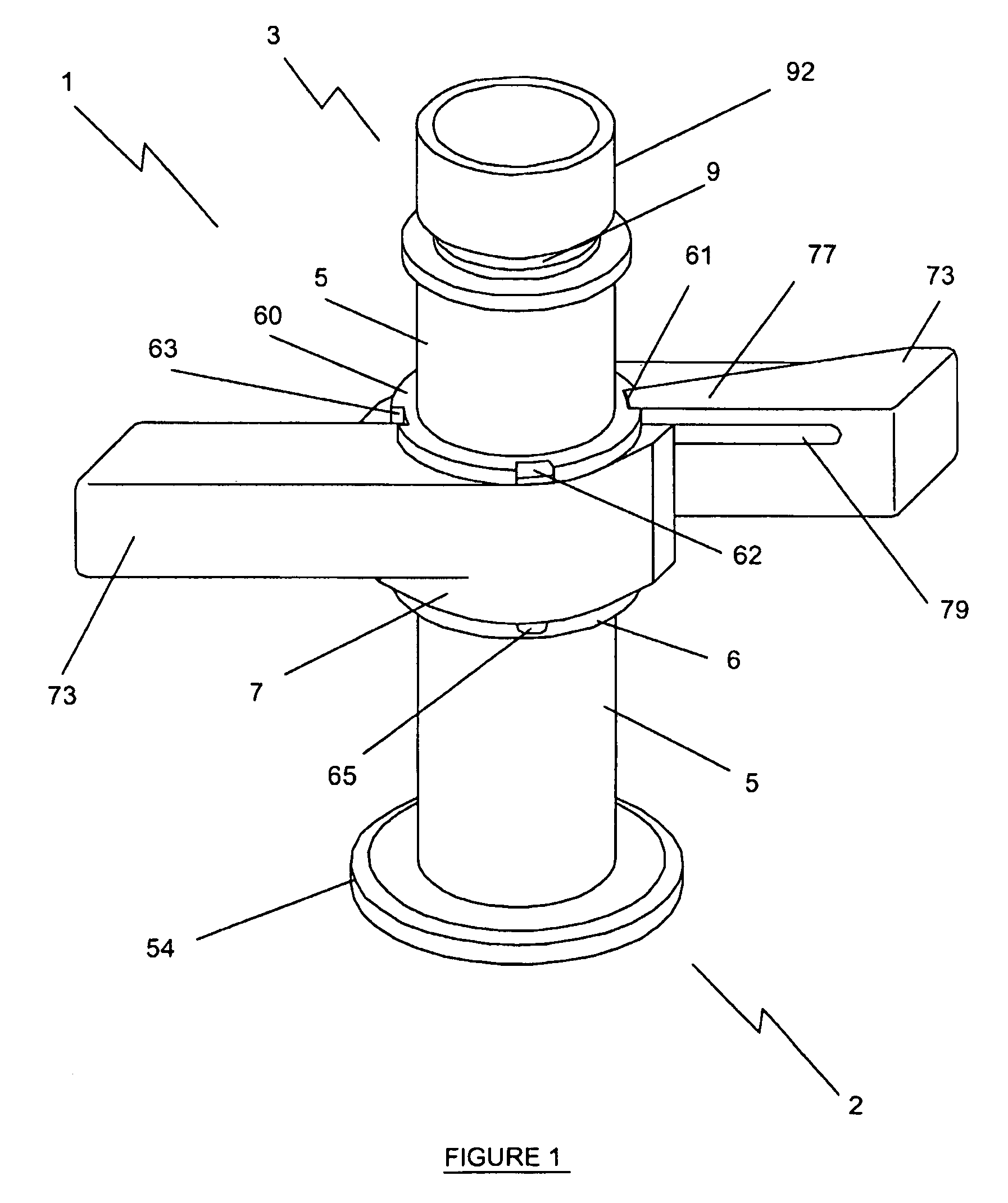

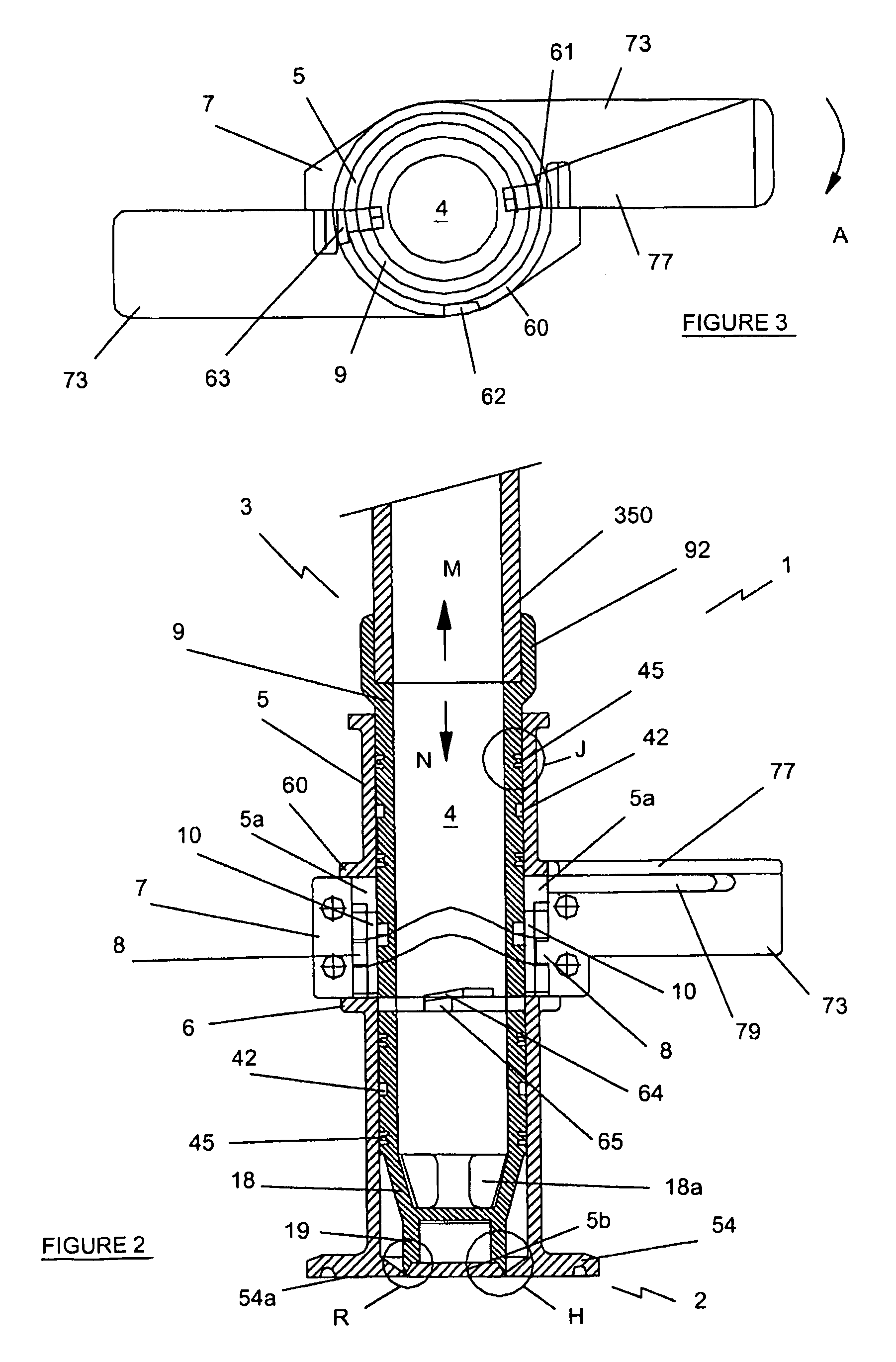

[0115]Referring to the drawings and initially to FIGS. 1 to 3, there is shown a valve indicated generally by the reference numeral 1. The valve 1 has a body having first and second open ends 2, 3 and a passageway 4 extending between the ends 2, 3.

[0116]The body of the valve 1 comprises a hollow tubular housing 5. A hollow tubular piston 9 is disposed within the housing 5. The piston 9 is movable along a longitudinal axis of the housing 5 by an actuator 7 rotatably mounted on the outside of the housing 5 and coupled to the piston 9 via a cam mechanism comprising a cam 8 of the actuator 7 and a pair of cam followers 10 mounted on the exterior of the piston 9. The housing 5, the actuator 7 and the cam mechanism will be described in detail below.

[0117]Referring to FIGS. 4 to 7 the housing 5 is provided by a hollow tube having an internal bore 510. First and second parallel spaced apart guide rails 6 and 60 respectively project laterally from the external surface of the housing 5. The first

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap