Dropping type safety decompression device

A pressure relief device and safety technology, applied in the direction of safety valve, valve device, functional valve type, etc., can solve the problems of high cost, complex manufacturing process, poor sealing performance of rupture disc, etc., and achieve simple manufacturing method and high sealing requirements. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

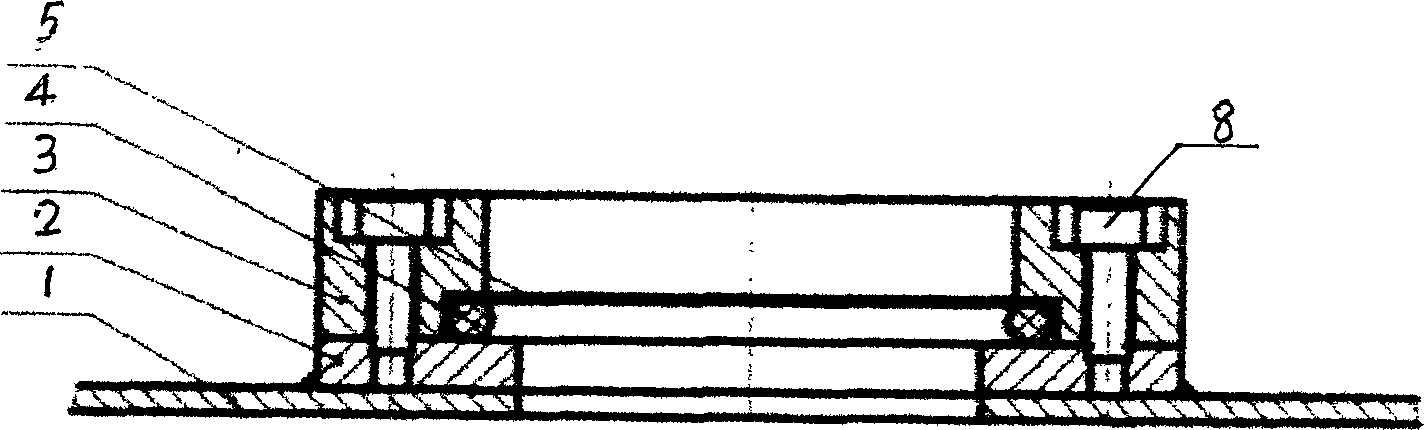

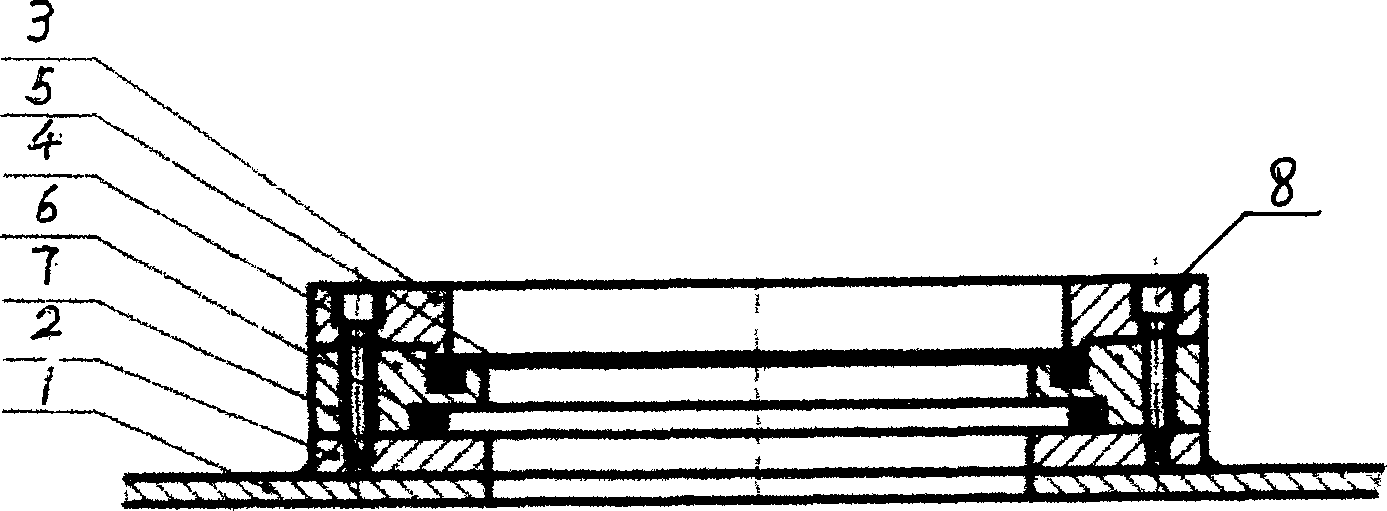

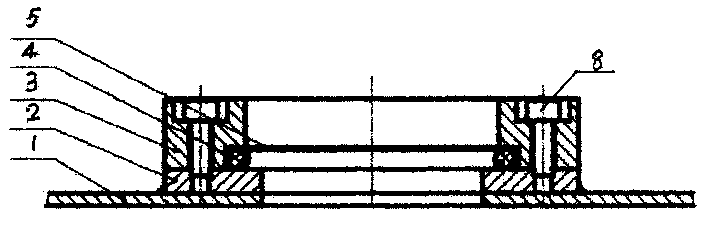

[0010] The present invention will be further described below with reference to the accompanying drawings.

[0011] A detachable safety pressure relief device according to the present invention is installed on the storage tank shell 1 . The operating pressure of the storage tank is 0.04MPa, and the design pressure is 0.25Mpa. Accordingly, the design pressure of the present invention is 0.1Mpa, and the discharge diameter is 240mm. The inner diameter of the upper page 3 of the holder is 255mm, the inner diameter of the container flange and the lower page 2 of the holder is 240mm, the outer diameter of the peeling piece 5 is 260mm, the thickness of the peeling piece 5 is 0.8mm, and the inner diameter of the O-ring 4 is 250mm , the outer diameter of the O-ring 4 is 262mm, and the deformation of the O-ring 4 after clamping is 3mm. After assembly, it is correctly installed on the tank shell 1, and it can work normally.

[0012] When the storage tank is overpressured, under the set bu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap