Heme and pyridyl metalloporphyrin co-assembled nano material as well as preparation method and application thereof

A nano-material and metal-based technology, applied in the field of material chemistry and electrochemical catalysis, can solve the problems of difficult to expose active sites, unable to form a controllable and orderly regulated bimetallic ratio, bimetallic spacing, etc., to meet equipment requirements The effect of low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] Example 1

[0033] A method for preparing Fe / M metal-doped graphitized carbon materials based on heme and pyridyl metalloporphyrin co-assembled nanomaterials, comprising the following steps:

[0034] (1) Prepare the NaOH solution of heme (referred to as Hemin / NaOH solution), the concentration of Hemin in NaOH solution is 0.01mol / L, and the solubility of NaOH solution is 0.02mol / L, and keep stirring at 25°C for 40 -45 min standby;

[0035] (2) Prepare the HCl solution of pyridyl metal cobalt porphyrin (CoTPyP) (denoted as CoTPyP / HCl solution), the concentration of MTPyP in the HCl solution is 0.01 mol / L, and the solubility of the HCl solution is 0.02 mol / L, and Stir continuously at 25°C for 40-45min for later use;

[0036] (3) Prepare a mixed solution of CTAB and NaOH solution, dissolve CTAB in water, add 38 μL of 1 mol / L NaOH solution, so that the volume of the solution is 9.5 mL and the concentration of CTAB in the solution is 0.01 mol / L;

[0037] (4)

Example Embodiment

[0042] Example 2

[0043] A method for preparing Fe / M metal-doped graphitized carbon materials based on heme and pyridyl metalloporphyrin co-assembled nanomaterials, the difference from Example 1 is that: take 200 μL step 1) and 300 μL respectively 2) The solution was quickly injected into the step 3) containing different volumes of 1 mol / L NaOH or 1 mol / L HCl solution, respectively containing 210 μL HCl, 80 μL HCl, 17 μL HCl, 6.90 μL NaOH, 9.05 μL NaOH, 9.92 μL NaOH In the solution, the pH values of the mixed solution were finally measured to be about 1.7, 2.2, 2.7, 3.7, 4.7, and 5.2 respectively. Stirring was continued for 48 hours at 25°C, and centrifuged. Fe / Co co-assembled materials with self-assembly ratio (2:3) at different pH values.

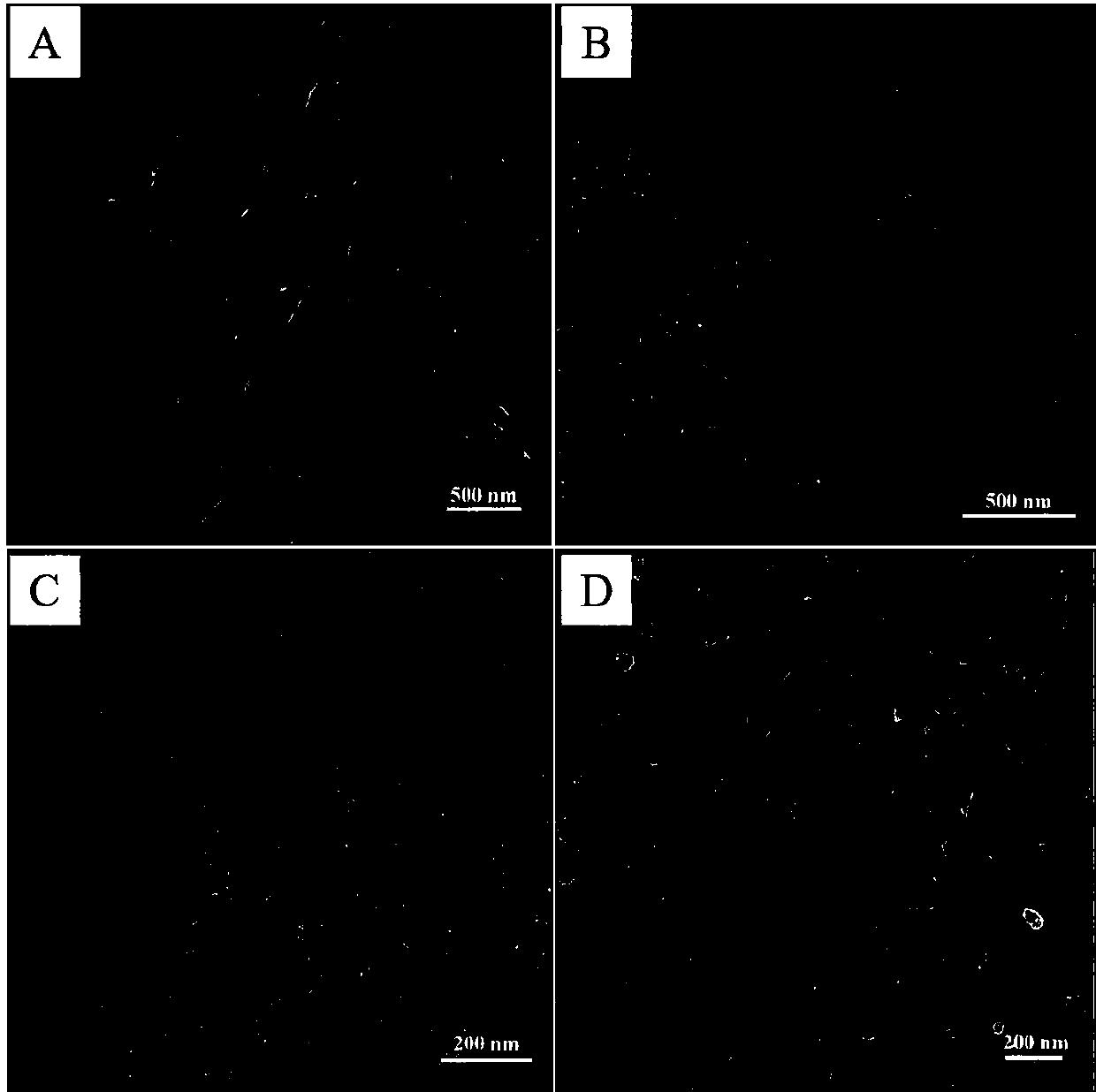

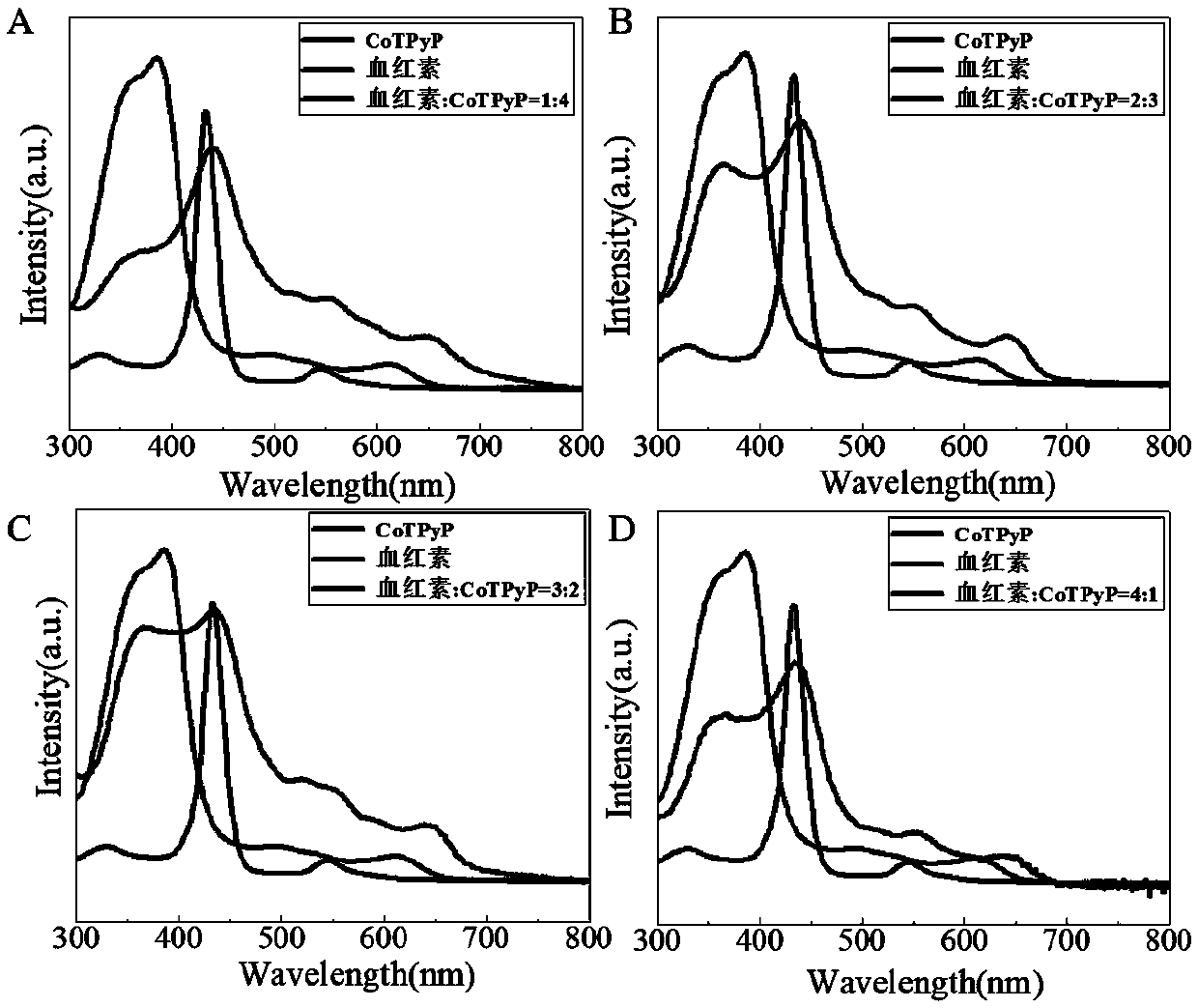

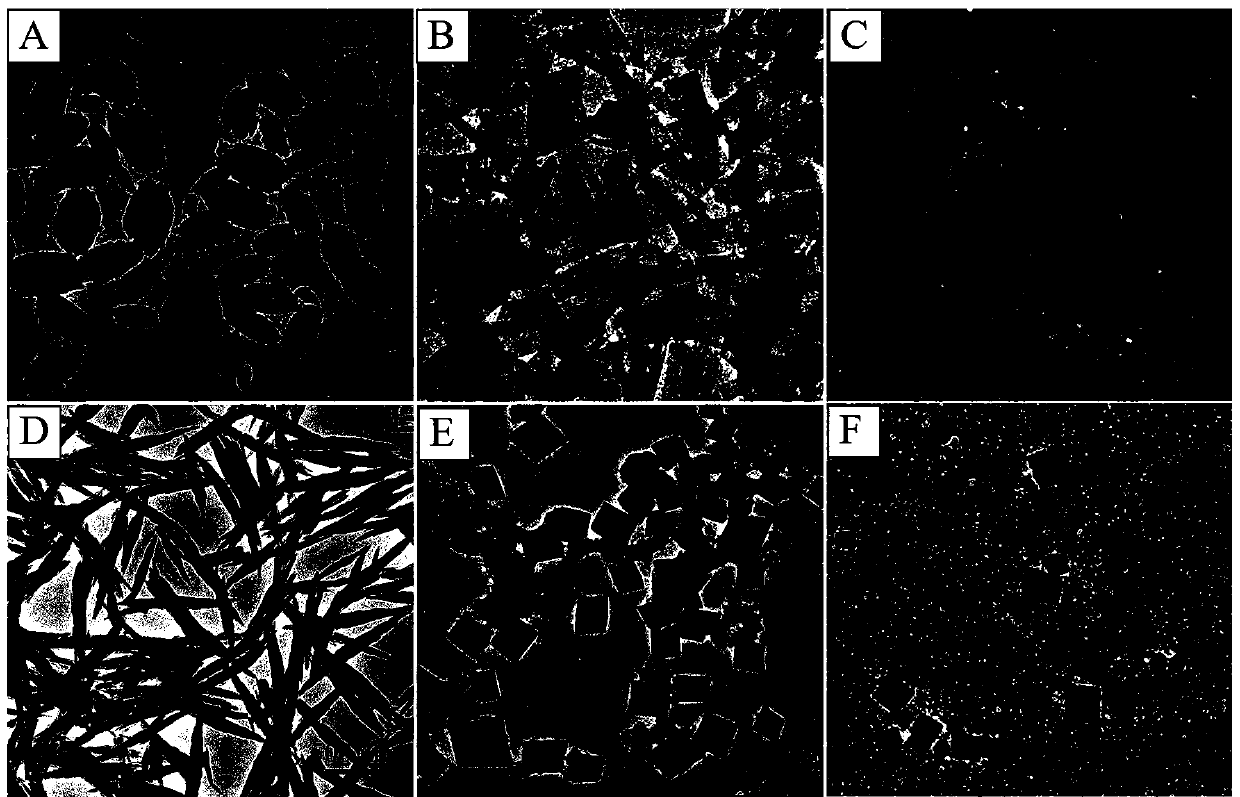

[0044] Different pH 1.7 ( image 3 A), 2.2 ( image 3 B), 2.7 ( image 3 C), 3.7 ( image 3 D), 4.7 ( image 3 E), 5.2 ( image 3 F), the SEM image of the co-assembly obtained under the same raw material ratio (2:3) image

Example Embodiment

[0045] Example 3

[0046] A method for preparing Fe / M metal-doped graphitized carbon materials based on heme and pyridyl metalloporphyrin co-assembled nanomaterials, the difference from Example 1 is that 0.01 mol / L in (2) Replace CoTPyP / HCl solution with 0.01mol / L ZnTPyP / HCl solution, take 250 μL (2) solution and 250 μL (1) solution respectively, and quickly inject them into 9.5 mL step 3) at the same time, and finally measure the pH value of the mixed solution is about 3.6, and a Fe / Zn co-assembled material with a self-assembly ratio of (1:1) is obtained. Then heat treatment according to Example 1, obtain the Fe / Zn double-doped graphitized carbon material with a carbon formation rate of 40%; Single-heterographitized carbon material; CoTPyP powder, the raw material for assembly, was heat-treated according to Example 1 to obtain a Co mono-heterographitized carbon material with a carbonization rate of 24%.

[0047] like Figure 4 as shown, Figure 4 As seen in A,

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap