Composite flow valve

A circulation valve and composite material technology, applied in sliding valves, valve details, control valves, etc., can solve the problems of high pressure, cost reduction, and low cost, and achieve the effects of no harm to health, cost reduction, and no harm to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

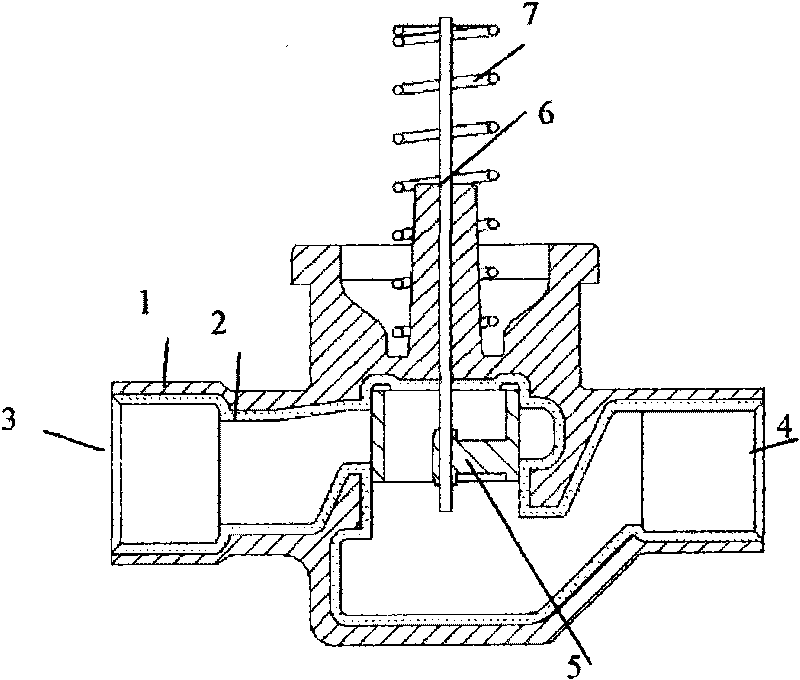

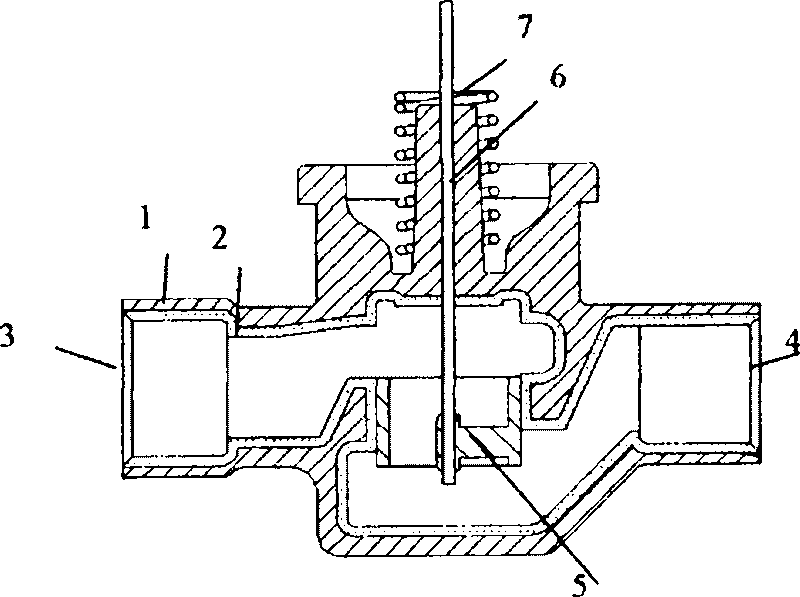

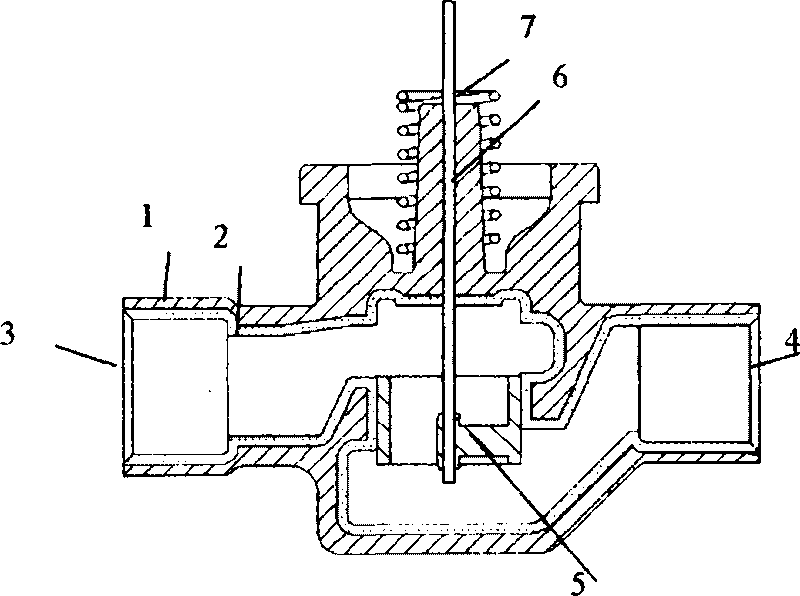

[0010] exist figure 1 , figure 2 Among them, the composite flow valve includes a valve base, a valve core (5), a valve core guide rod (6), a pressure spring (7), a valve inlet (3) of a fluid inlet, and a valve outlet (4) of a flow outlet. The valve base is composed of an outer valve base shell (1) and an inner liner (2), the inner surface of the outer valve base shell (1) is put into the inner liner (2), and the two are closely combined to form a composite material. Again figure 1 , figure 2 In the composite flow valve as a one-way valve, when the fluid pressure at the valve inlet (3) is greater than the fluid pressure at the valve outlet (4), the valve core (5) opens along the valve core guide rod (6), and the fluid passes through. When the fluid pressure at the valve outlet (4) is greater than the valve inlet (3), the valve core (5) closes along the valve core guide rod (6), and the inner liner (2) with a certain thickness acts as the contact surface of the fluid, which ca

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap