Universal battery structure adopting lithium battery material

A lithium battery material and battery technology, applied in secondary battery charging/discharging, secondary battery repair/maintenance, etc., can solve the problems of high development cost and inability to take into account different electrical appliances, so as to prolong life and prevent overcharging and over-discharge, to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

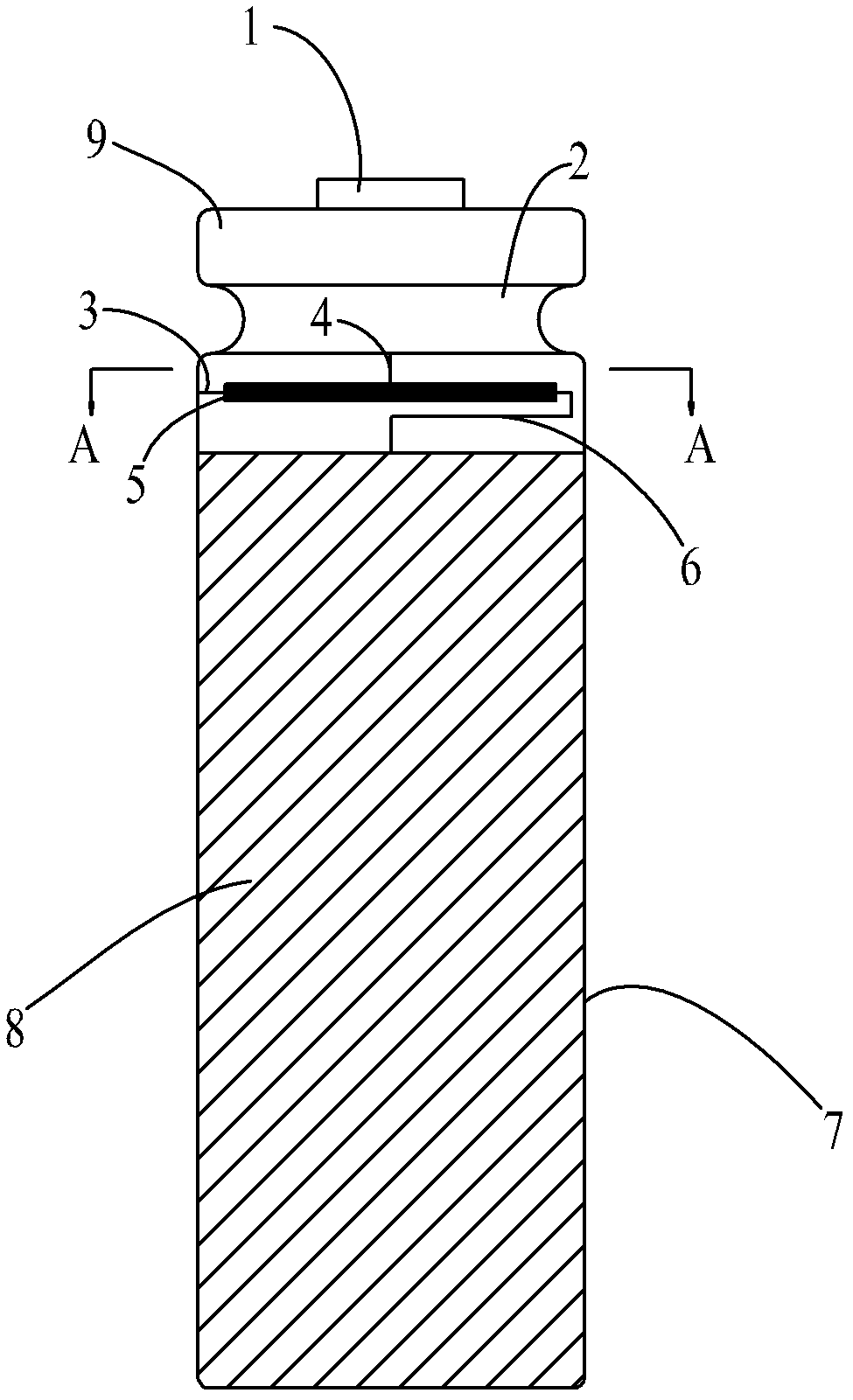

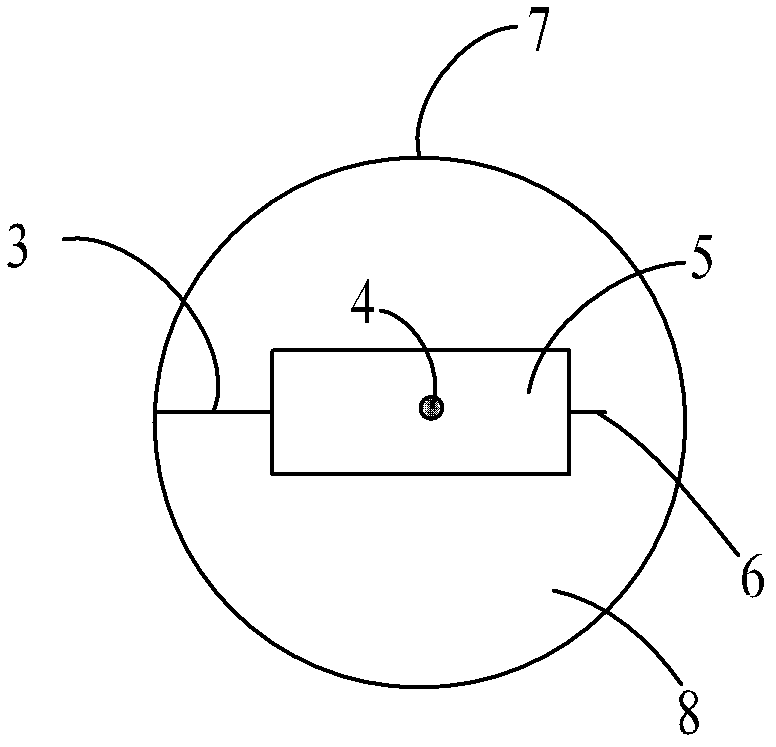

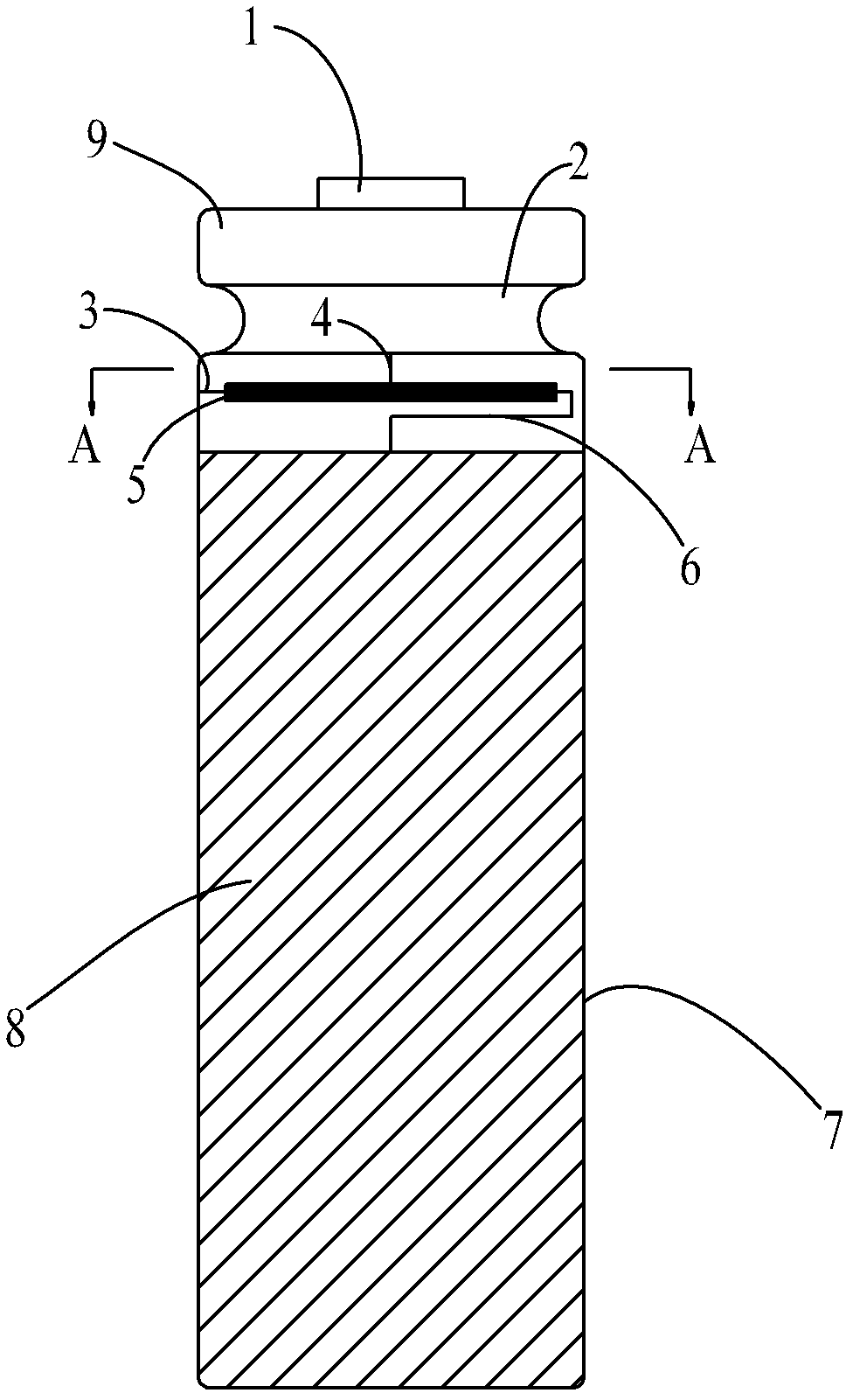

[0025] The standard AAA (flat head) battery is AAA battery, the standard height is 43.6±0.5mm, and the diameter is 10.1±0.2mm. Common uses include household remote controllers, small flashlights, electric toys, etc. It is one of the most common types of batteries. The AAA batteries that are common on the market now include dry batteries, alkaline manganese batteries, nickel-metal hydride batteries, etc., and the battery capacity is about 900 mAh.

[0026] With the standard AAA battery that the present invention makes, the inner diameter of battery is about 9.8mm, so the protective plate 5 inner diameter that selects is about 9.5mm. The thickness of the positive electrode of lithium iron phosphate is generally about 130mm, the thickness of the negative electrode is about 110mm, and the thickness of the diaphragm is about 20mm. Because the diaphragm has two layers, the thickness of the general negative electrode, positive electrode and diaphragm is estimated to be about 280mm. Acco

example 2

[0028] The standard AA (flat head) battery is the fifth battery, the standard height is 48.0±0.5mm, and the diameter is 14.1±0.2mm. Common uses include household remote controllers, electronic devices, flashlights, small household appliances, electric toys, etc., and it is also one of the most commonly used batteries. The common AA batteries on the market now include dry batteries, alkaline manganese batteries, nickel metal hydride batteries, nickel cadmium batteries, etc., and the battery capacity is about 1400 mAh.

[0029] With the standard AA battery made by the present invention, the inner diameter of the battery is about 14mm, so the inner diameter of the protective plate selected is about 13.8mm. The thickness of the negative electrode, positive electrode and diaphragm of lithium iron phosphate is estimated to be about 280mm. According to the inner diameter of the battery, the cross-sectional area of the battery can be estimated to be 153.86mm 2About, in this cross-sect

example 3

[0031] The standard D-type battery is the No. 1 battery, the height of the standard mix is 59.0±0.5mm, and the diameter is 32.3±0.2mm. Common uses include kitchen stove igniters, flashlights, lighting in unlit areas, backup batteries, etc., and it is also one of the most commonly used batteries. The common No. 1 batteries on the market now include dry batteries, alkaline manganese batteries, nickel-metal hydride batteries, nickel-cadmium batteries, etc., and the battery capacity is about 3000 mAh.

[0032] The inner diameter of the standard D-type battery made by the present invention is about 34mm, so the inner diameter of the protective plate selected is about 33.8mm. The thickness of the negative electrode, positive electrode and diaphragm of lithium iron phosphate is estimated to be about 0.28mm. According to the inner diameter of the battery, the cross-sectional area of the battery can be estimated to be 907.46mm 2 About, in this cross-sectional area, the length of the

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap