Double-damping high-pressure back pressure valve without diaphragm

A back pressure valve, non-diaphragm technology, used in safety valves, balance valves, valve devices, etc., can solve the problems of reducing the wear speed of back pressure valves, and achieve the effects of smooth pulse, prolong service life and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

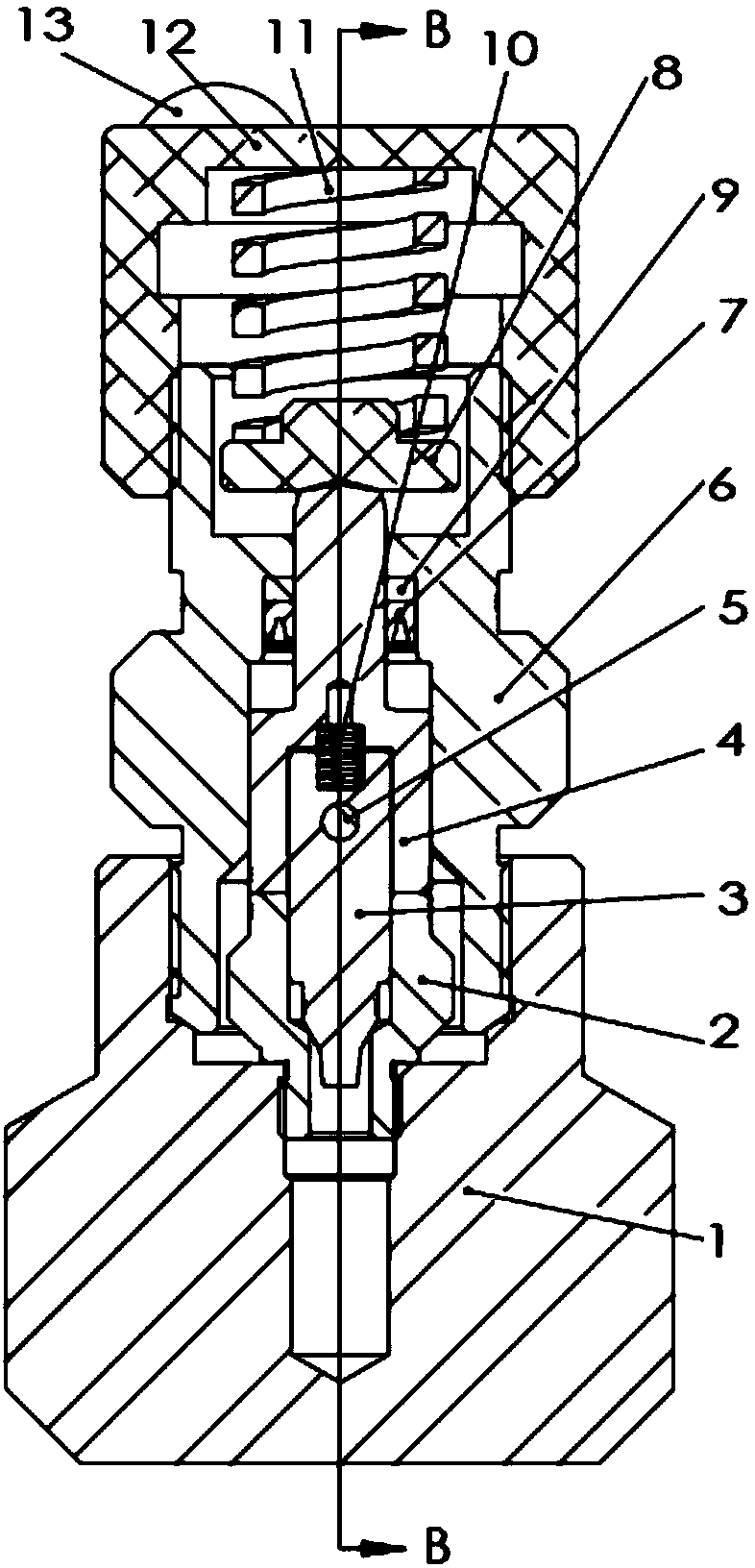

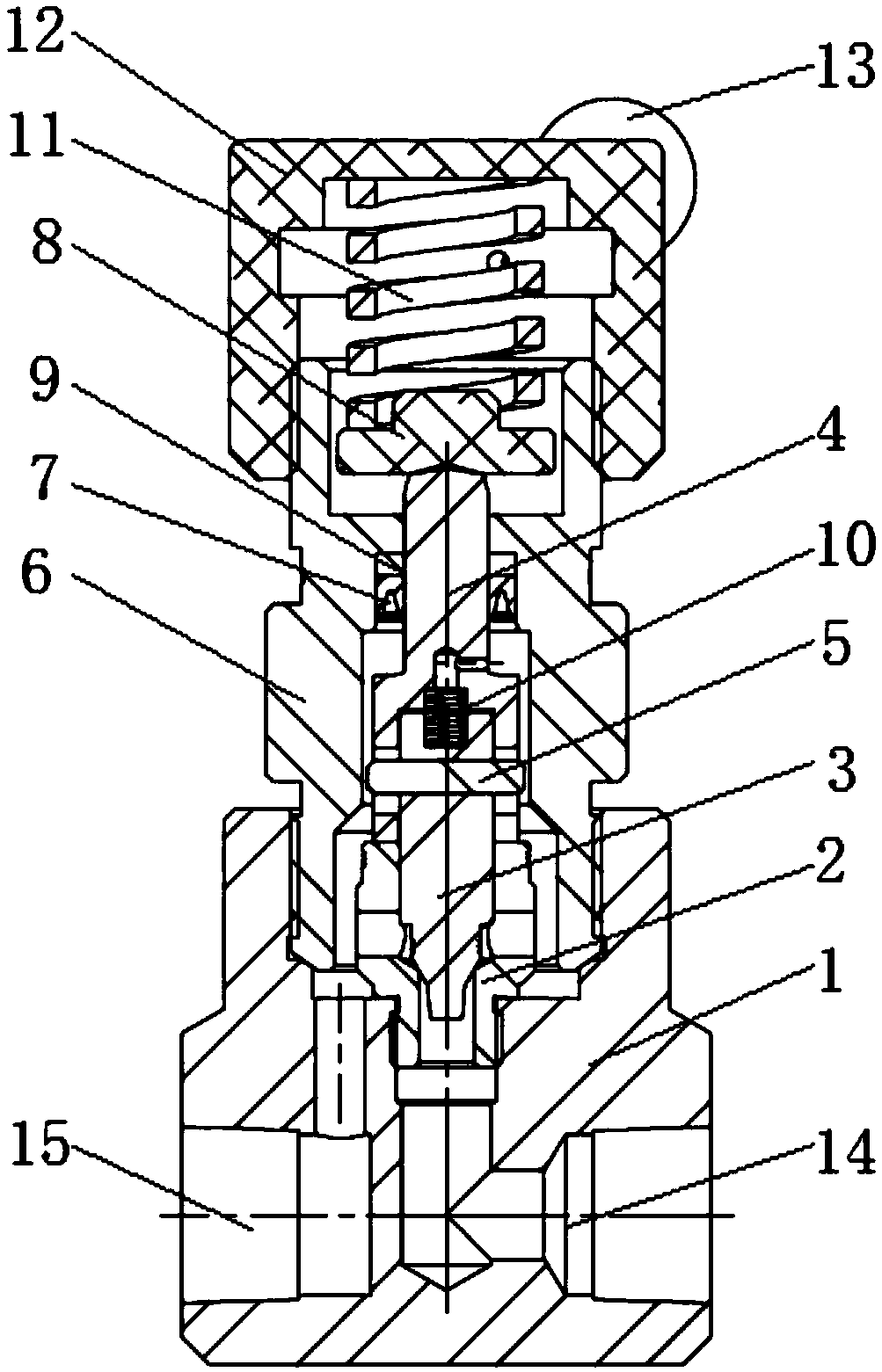

[0026] A double damping non-diaphragm high pressure back pressure valve, such as figure 1 , figure 2 As shown, it includes main valve body 1, auxiliary valve body 2, main valve core 3, auxiliary valve core 4, decompression cylinder 6, valve core pressing plate 8, auxiliary spring 10, main spring 11 and main spring gland 12, auxiliary valve The body 2 is set in the main valve body 1, the lower end of the decompression cylinder 6 is connected with the main valve body 1, the upper end is connected with the main spring cover 12, the main valve core 3 is set in the decompression cylinder 6, the lower end of the main valve core 3 is connected with the auxiliary The valve body 2 is sealed or separated to realize the opening and closing of the back pressure valve. The upper end of the main valve core 3 is connected to the auxiliary valve core 4, and the upper end of the auxiliary valve core 4 is connected to the valve core pressure plate 8. Between the valve core pressure plate 8 and th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap