Self-powering three-way change valve

A three-way reversing valve, self-operated technology, applied in the direction of fluid circulation arrangement, refrigeration components, refrigerators, etc., can solve the problems of short-circuit leakage of high and low pressure chambers, local resistance increase, reversing pressure difference, etc., to ensure stability performance and reliability, improve cooling efficiency, and reduce local resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

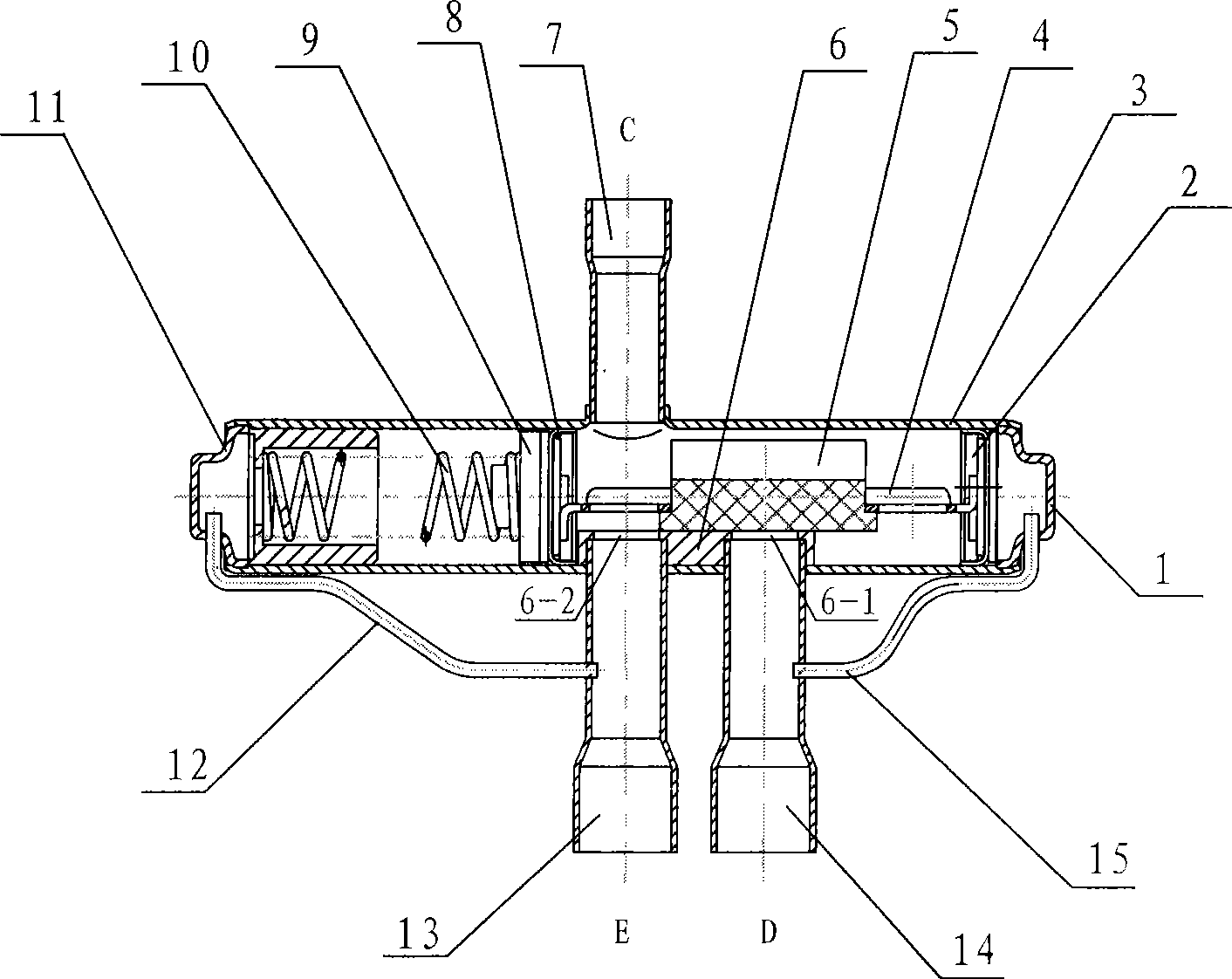

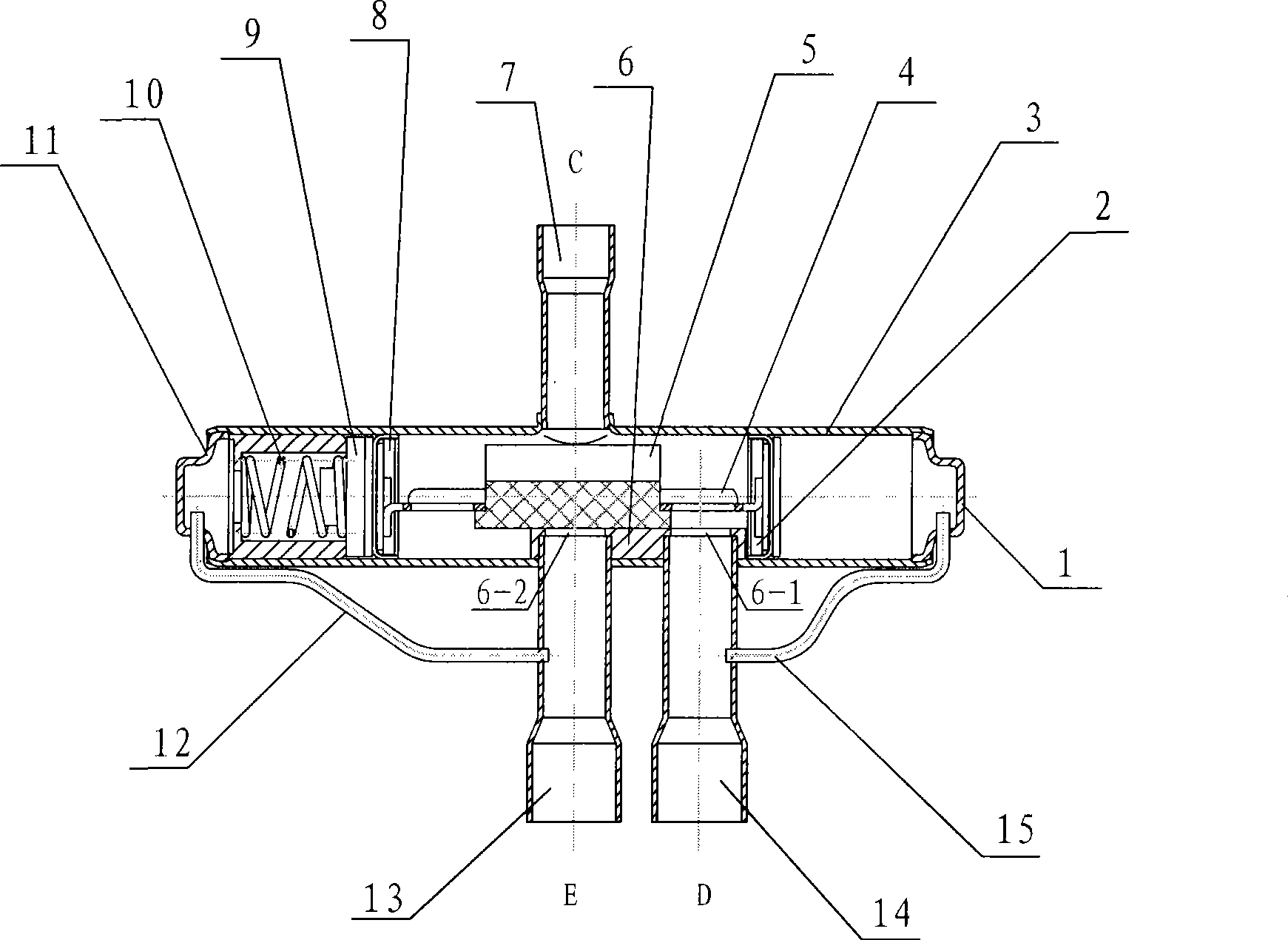

[0018] Such as figure 1 As shown, the self-operated three-way reversing valve of the present invention includes a valve body 3, the two ends of the valve body 3 have a left end cover 11 and a right end cover 1, a piston one 2, a piston two 8 in the valve body 3, a slide 4. Slider 5, and spring 10, the valve seat 6 on the valve body 3, the connecting pipe C7, the connecting pipe E13, the connecting pipe D14, the low-pressure capillary 12, and the high-pressure capillary 15 form a cavity after brazing; The block 5 is placed on the valve seat 6, the slide frame 4 is fixed with the slide block 5, and the slide frame 4 is connected with the piston one 2 and the piston two 8 to form a combination piston slide frame, which can move axially in the valve body 3 ; The spring 10 is located between the piston 2 8 and the left end cover 11, and the valve seat 6 has two valve ports. The above structure is similar to the prior art, so it will not be described in detail.

[0019] The biggest f

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap