Coupler

a coupler and female technology, applied in the field of female couplers, can solve the problems of excessive force on the pawl operator, adversely affecting human beings, and inability to operate during supply, and achieve the effect of high reliability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

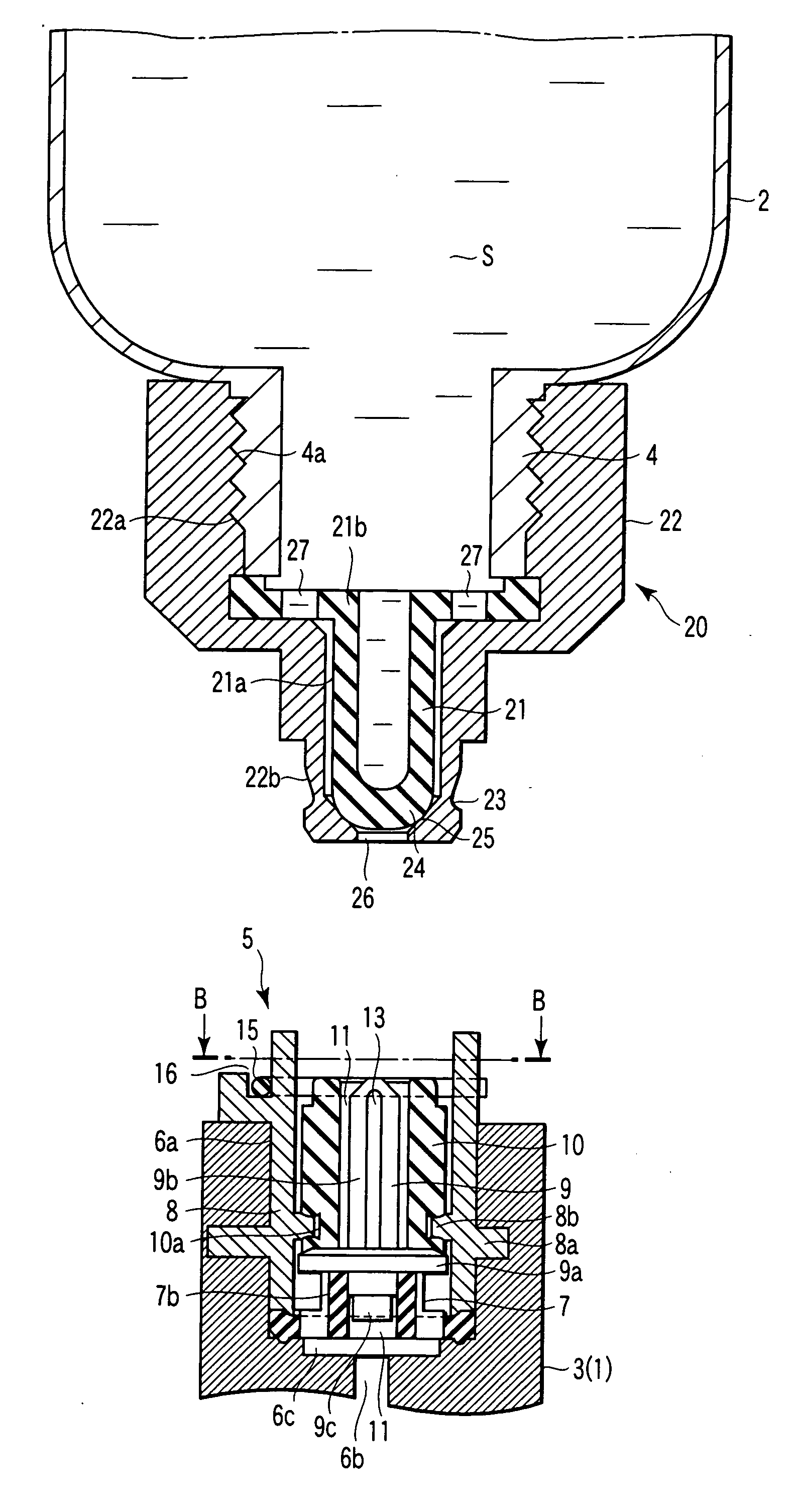

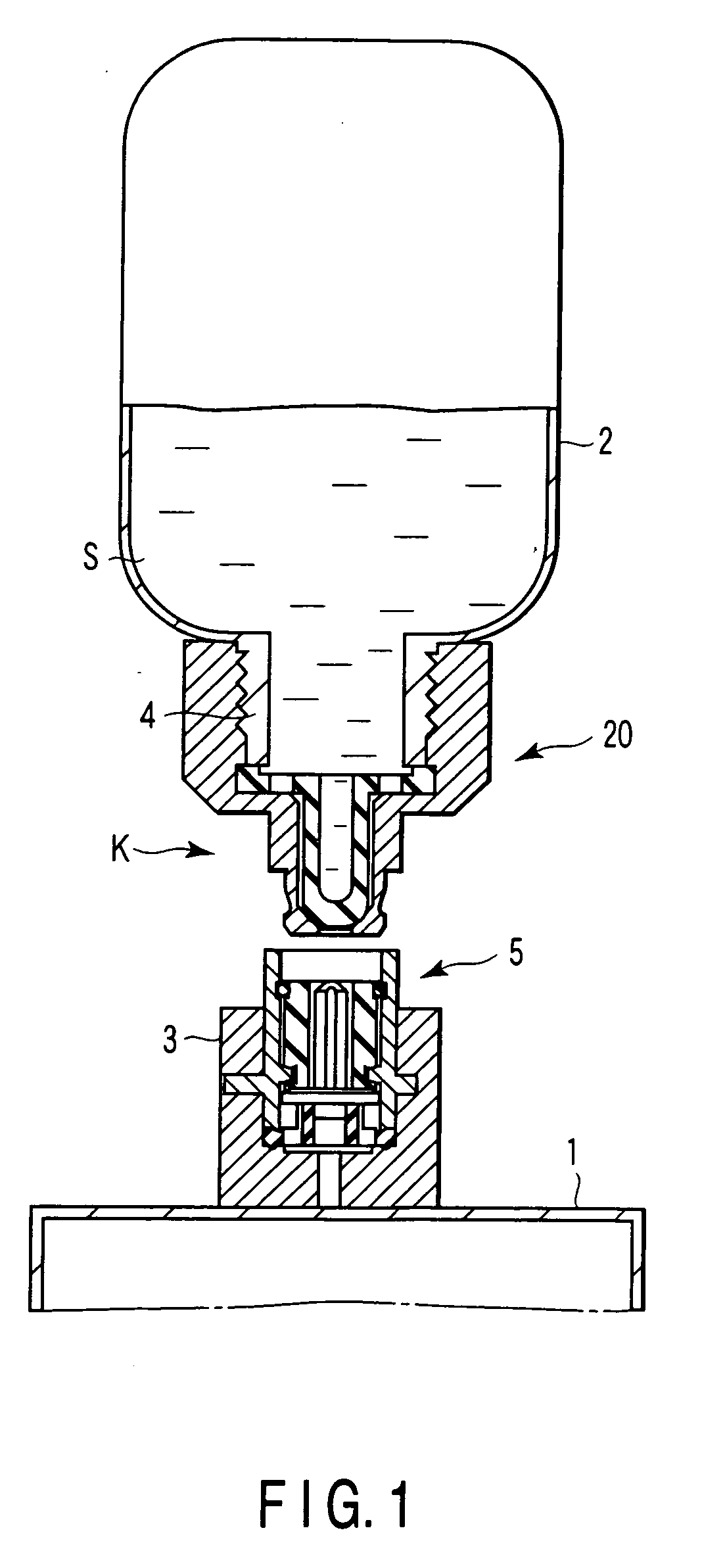

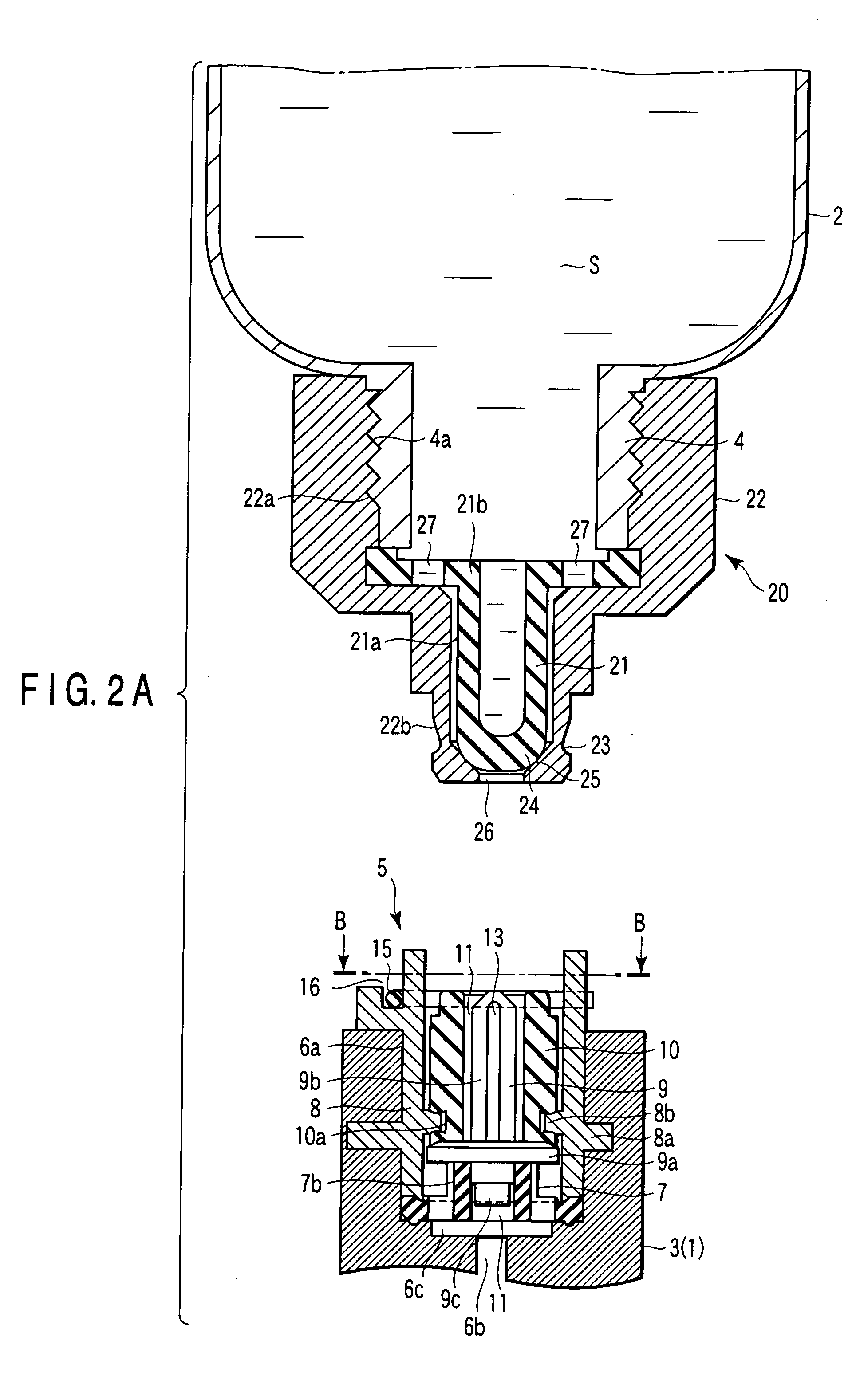

[0041] With reference to the drawings, description will be given below of a coupler according to an embodiment of the present invention.

[0042]FIG. 1 shows the configuration of a fuel cell coupler K in a position in which, for example, a cell solution S is supplied.

[0043] Reference numeral 1 at the bottom of FIG. 1 denotes a cell container (solution tank) constituting a fuel cell. Reference numeral 2 at the top of FIG. 1 denotes a supply container (liquid retaining container) in which the cell solution S is stored. When the cell solution S from the supply container 2 is supplied to the cell container 1, the supply container 2 takes a position shown in FIG. 1. However, in a normal state, the supply container 2 is maintained in a position in which it is turned upside down.

[0044] An injection port 3 is projected from the upper end of the cell container 1. A supply port 4 is projected from the lower end of the supply container 2 in FIG. 1. A female coupler 5 is attached to the injection

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap