Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Inlet pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inlet pressure describes the pressure available where the suction pipe meets the booster pump. The inlet pressure derives from the pressure of the water supplier or the water pressure created if the booster draws from a break tank.

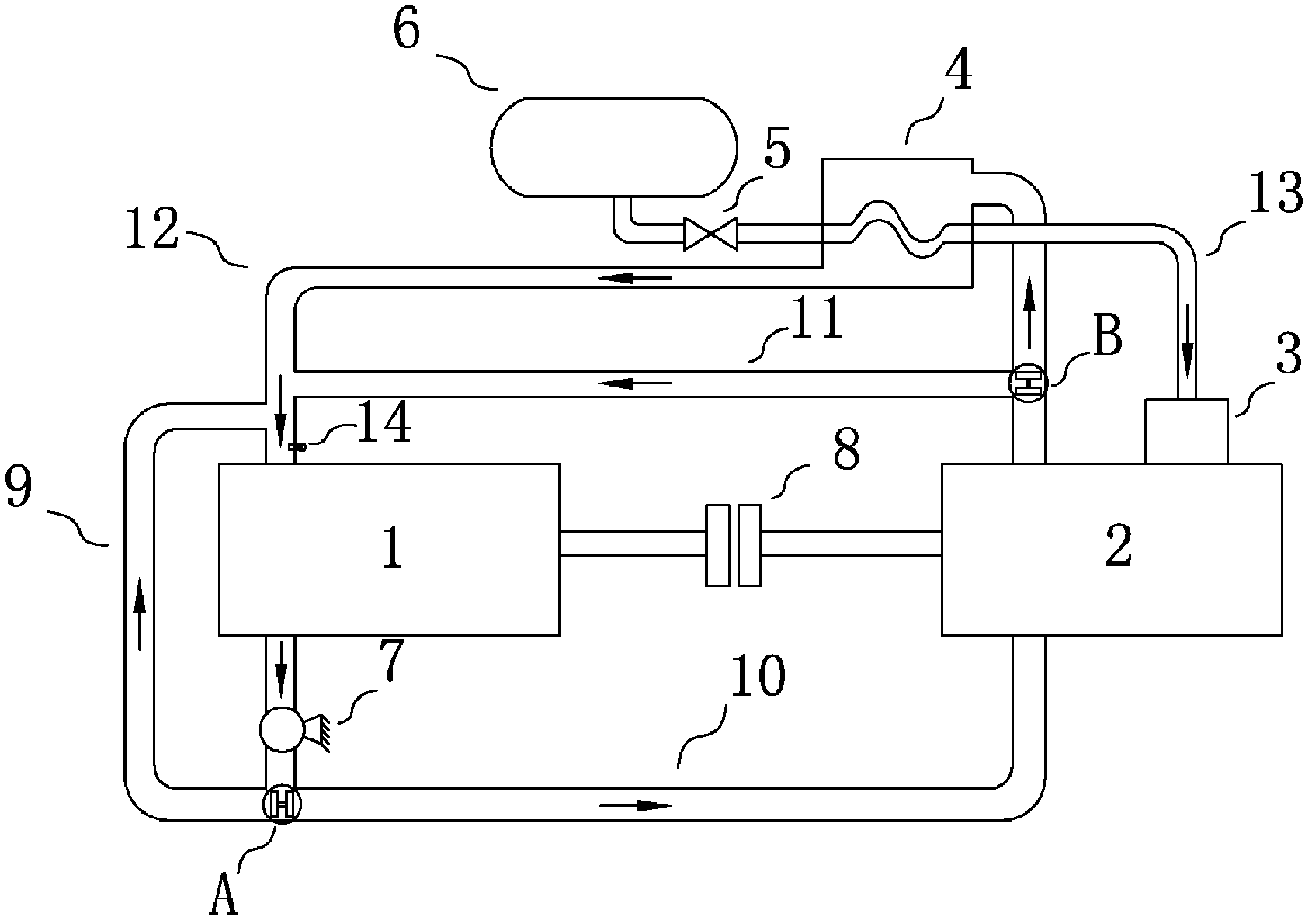

Pneumatic and internal combustion hybrid system based on multi-stage utilization of afterheat of cooled water

InactiveCN102505998AImprove working environmentIncrease cycle power outputCoolant flow controlInternal combustion piston enginesThermostatInlet pressure

Owner:ZHEJIANG UNIV

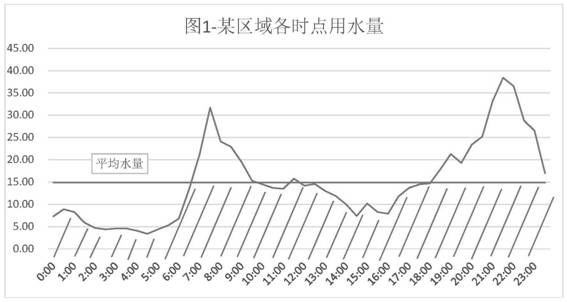

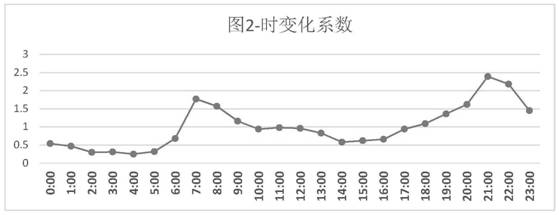

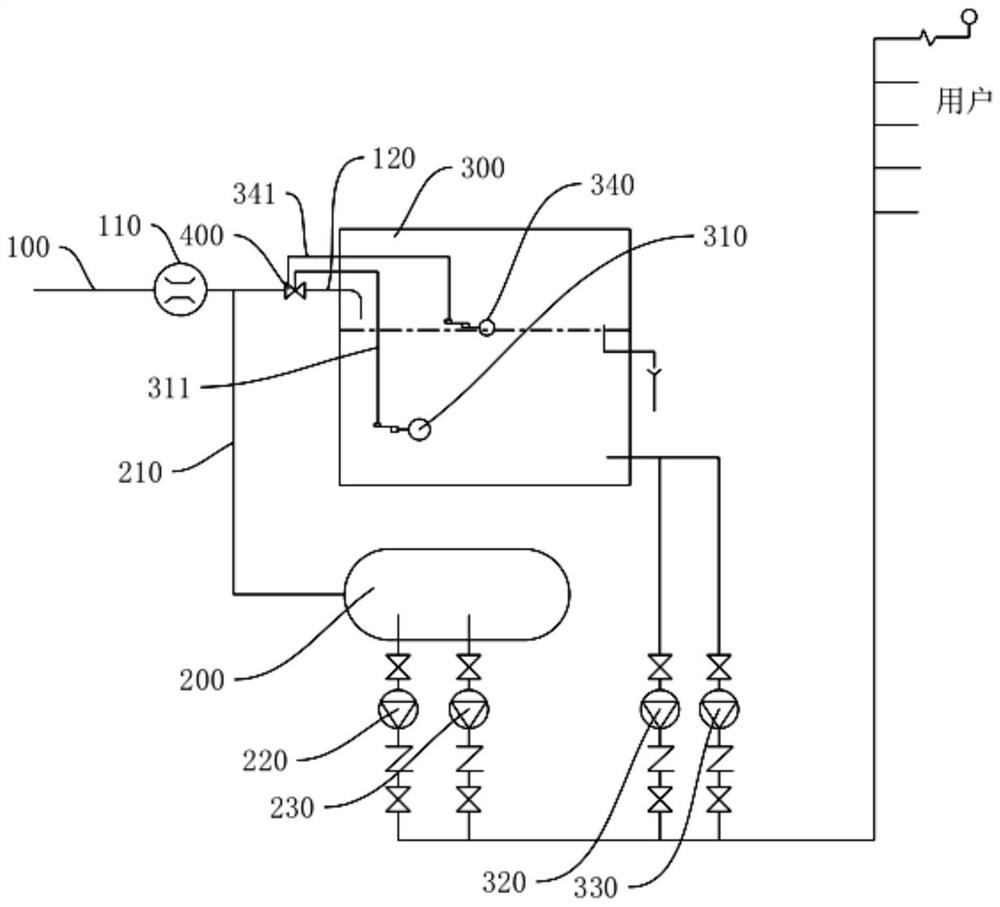

Energy-saving non-negative pressure equipment and control method

PendingCN112942488ASave running electricityProtect interestsService pipe systemsWater mainsWater useLine tubing

Owner:凯特数智科技有限公司

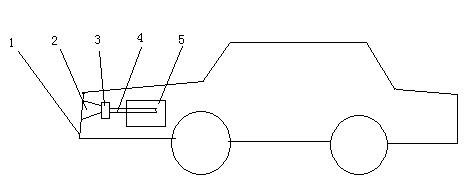

Breathing boost device of automobile engine

InactiveCN102168635AIncreased air intakeIncrease powerMachines/enginesAir intakes for fuelAir filterEngineering

Owner:SHAOXING UNIVERSITY

Valve seat automatic compensation one-way valve structure

The invention relates to a valve seat automatic compensation one-way valve structure. The valve seat automatic compensation one-way valve structure comprises a valve body (3), an automatic adjusting valve seat mounted in the valve body (3) to move up and down and a valve ball (4) placed on the automatic adjusting valve seat. Compared with the prior art, when inlet pressure is difference, the position height of a valve seat is automatically adjusted, then the maximum lift height of the valve ball is adjusted, quite stable flow is kept, and when a diaphragm moves towards the diaphragm oil side protection disc, impacting to the protection disc and the influence on the drive end are reduced.

Owner:MILTON ROY IND SHANGHAI

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap