Numerical control proportional valve

A proportional valve and valve seat technology, which is applied in the field of proportional valves for constant temperature gas water heaters, can solve the problems of large volume, high cost, and low firepower, etc., and achieve the effect of small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

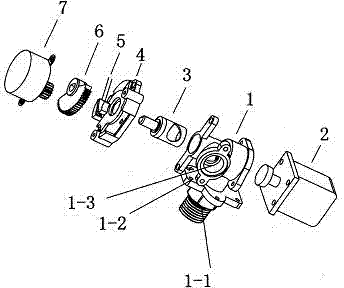

[0022] Depend on figure 2 It can be seen that the numerical control proportional valve includes: valve seat (1) solenoid valve (2) air valve core (3) air valve core pressure plate (4) return switch (5) gear (6) stepping motor (7) composition. The inlet pipe (1-1) of the valve seat (1) is inlaid with a fixed plate (1-2), and the air outlet (1-3) faces forward or upward; the solenoid valve (2) is located on the right side of the valve seat (1) , the air valve core (3) is located on the left side of the valve seat (1), and is fixed in the valve seat (1) by the air valve core plate (4), and the other end of the air valve core (3) is connected to the gear (6); The motor (7) is fixed on the air valve core pressure plate (4), the upper gear of the stepping motor (7) meshes with the gear (6), and the reply switch (5) is fixed on the air valve core pressure plate (4); When the upper gear of the stepping motor (7) pushes the gear (6) to press the return switch (5) to close, at this ti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap