Shut-off valve for liquid and gaseous media

A technology of gaseous medium, stop valve, applied in the direction of valve details, valve device, valve operation/release device, etc., to achieve the effect of keeping reaction and switching time, saving weight and simple exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

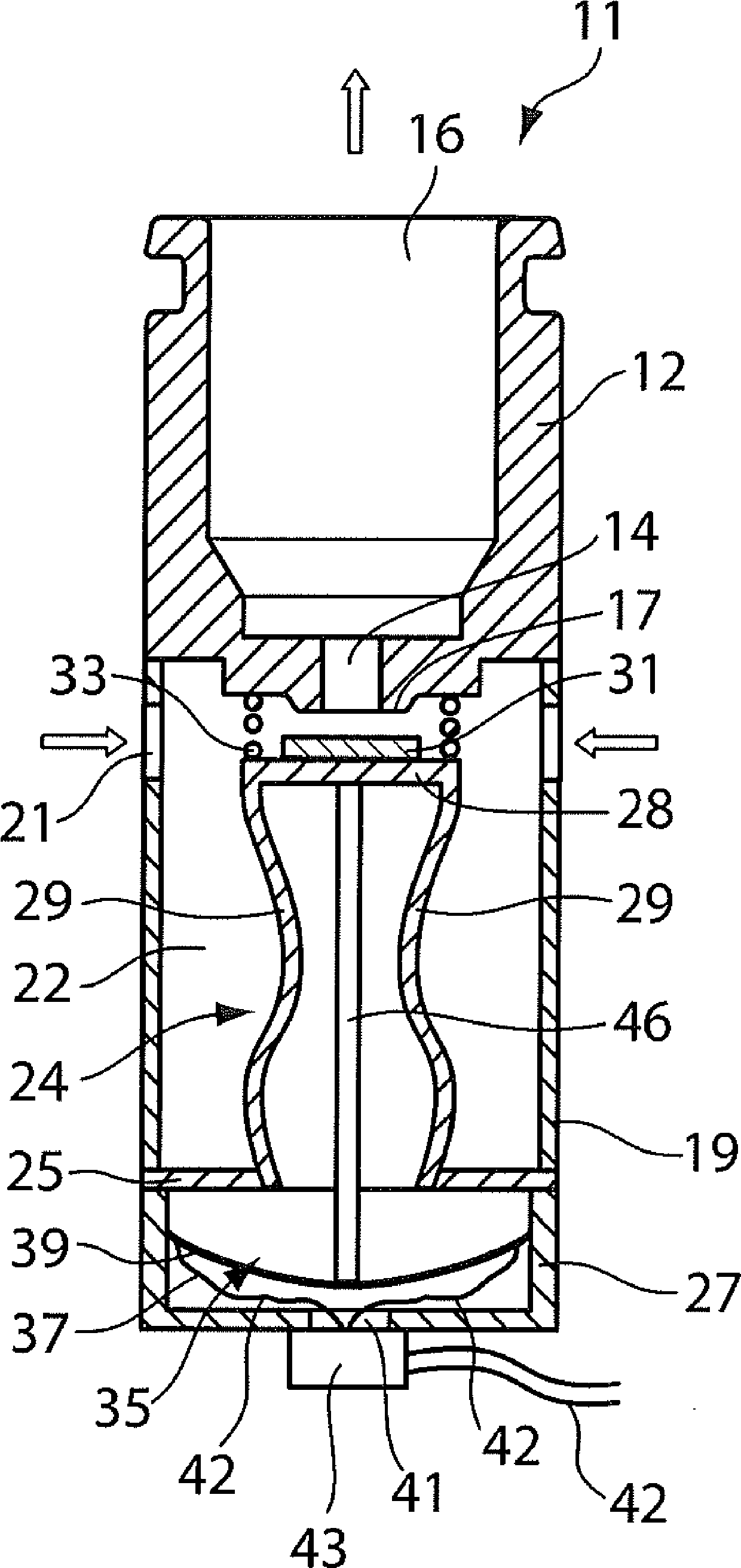

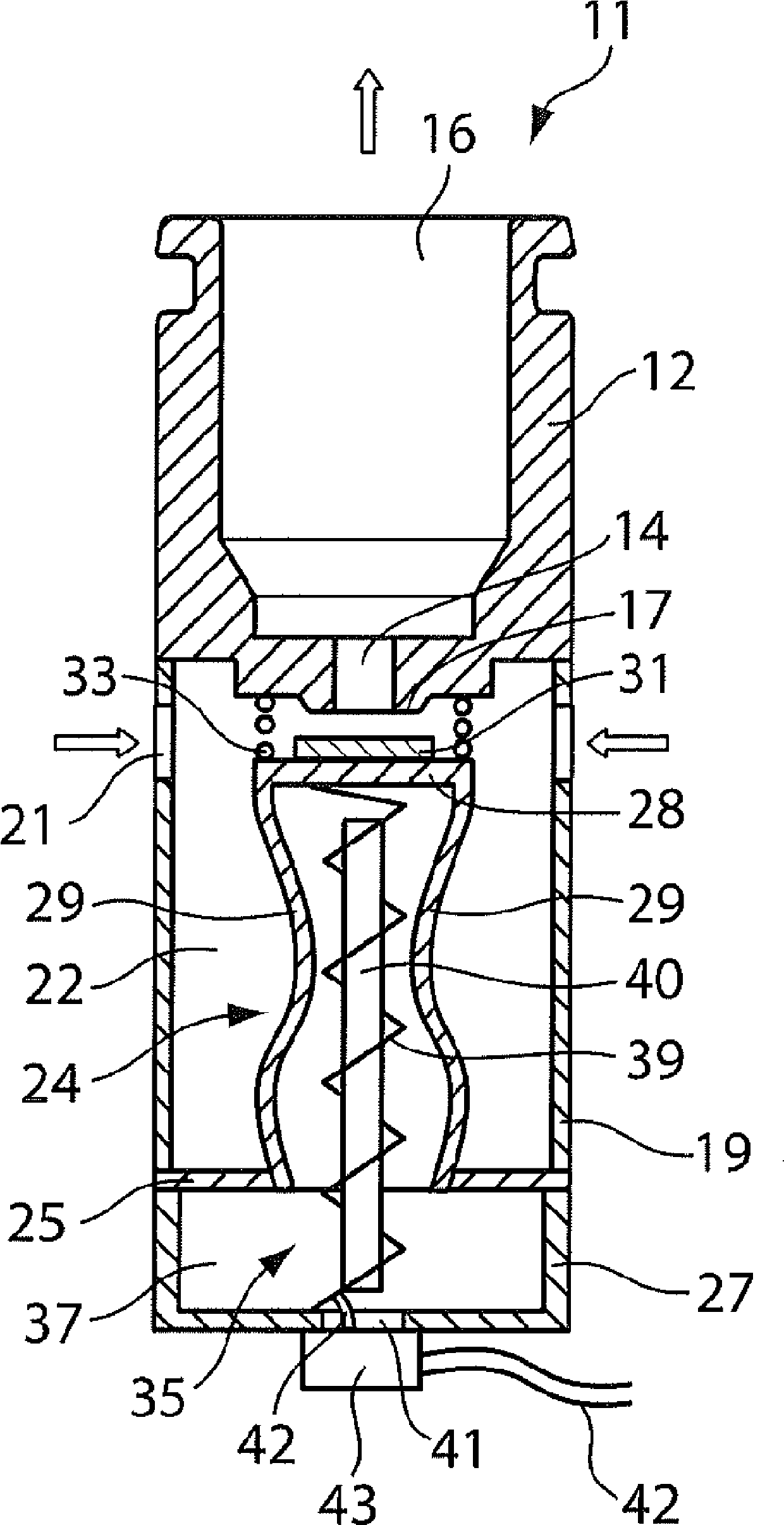

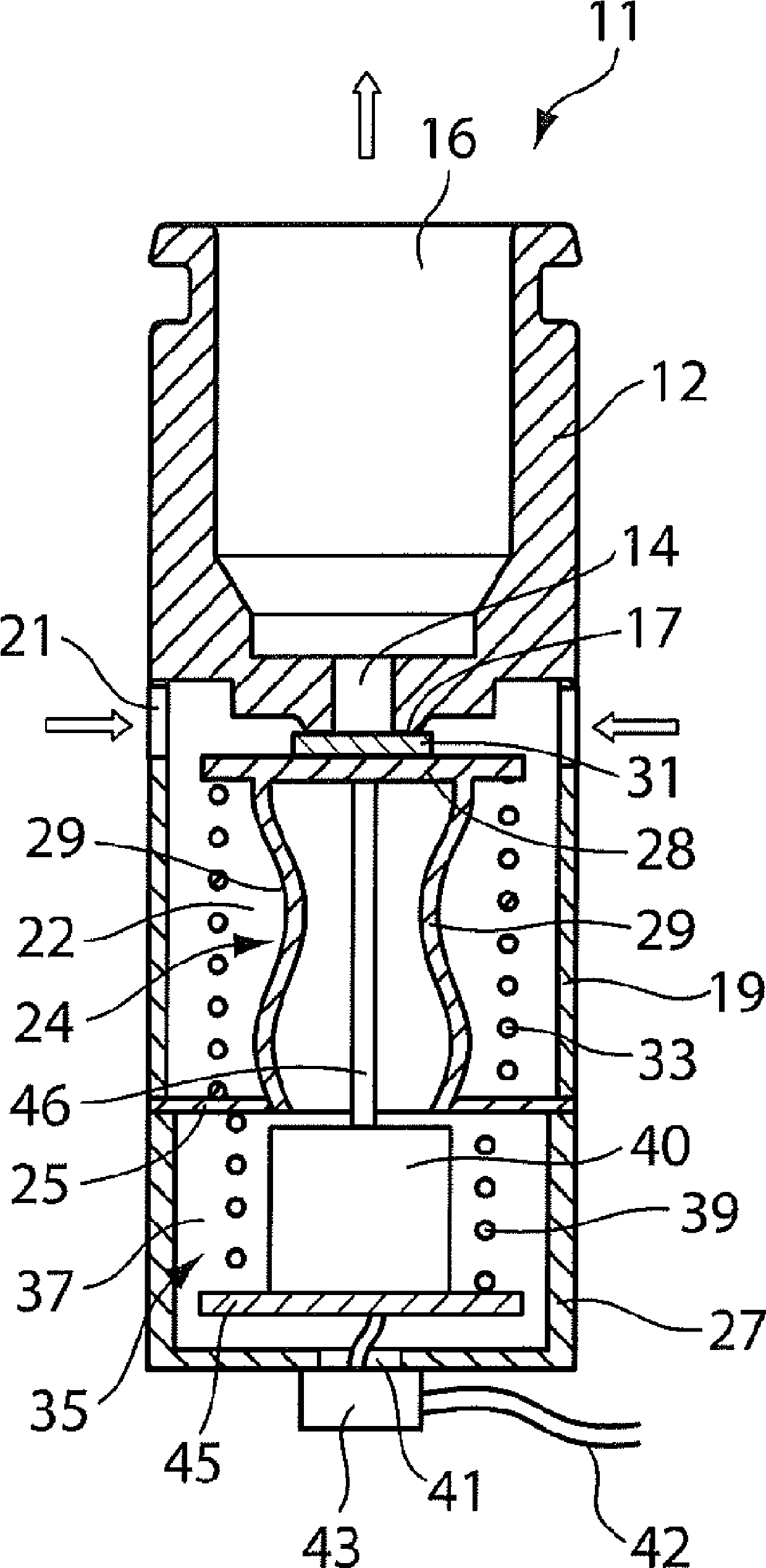

[0028] exist figure 1 A schematic cross-sectional view of a first embodiment of the shut-off valve 11 according to the invention is shown in FIG. The shut-off valve 11 is designed as a so-called NO valve (Normally Open valve), the function of which will be described below.

[0029] The shut-off valve 11 comprises a valve housing 12 which has a passage opening 14 which opens into a discharge opening 16 . A valve seat 17 is arranged on the opposite end of the passage hole 14 , which valve seat may for example be formed as a crater-like protrusion. A sleeve-shaped housing part 19 is also arranged on the valve housing 12 . The housing part 19 may be arranged as a single piece on the valve housing 12 . Alternatively, the housing part 19 can also be attached to the valve housing 12 by a releasable connection (eg a screw connection) or by a firmly glued connection. The sleeve-shaped housing part 19 has at least one inlet opening 21 through which a liquid or gaseous medium is led int

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap