Sealing device and method of mounting same

A sealing device and sealing lip technology, used in valve devices, engine sealing, charging systems, etc., can solve the problems of difficult to pass through wire filters, intrusion into bearings, etc., and achieve excellent sealing performance and large initial interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

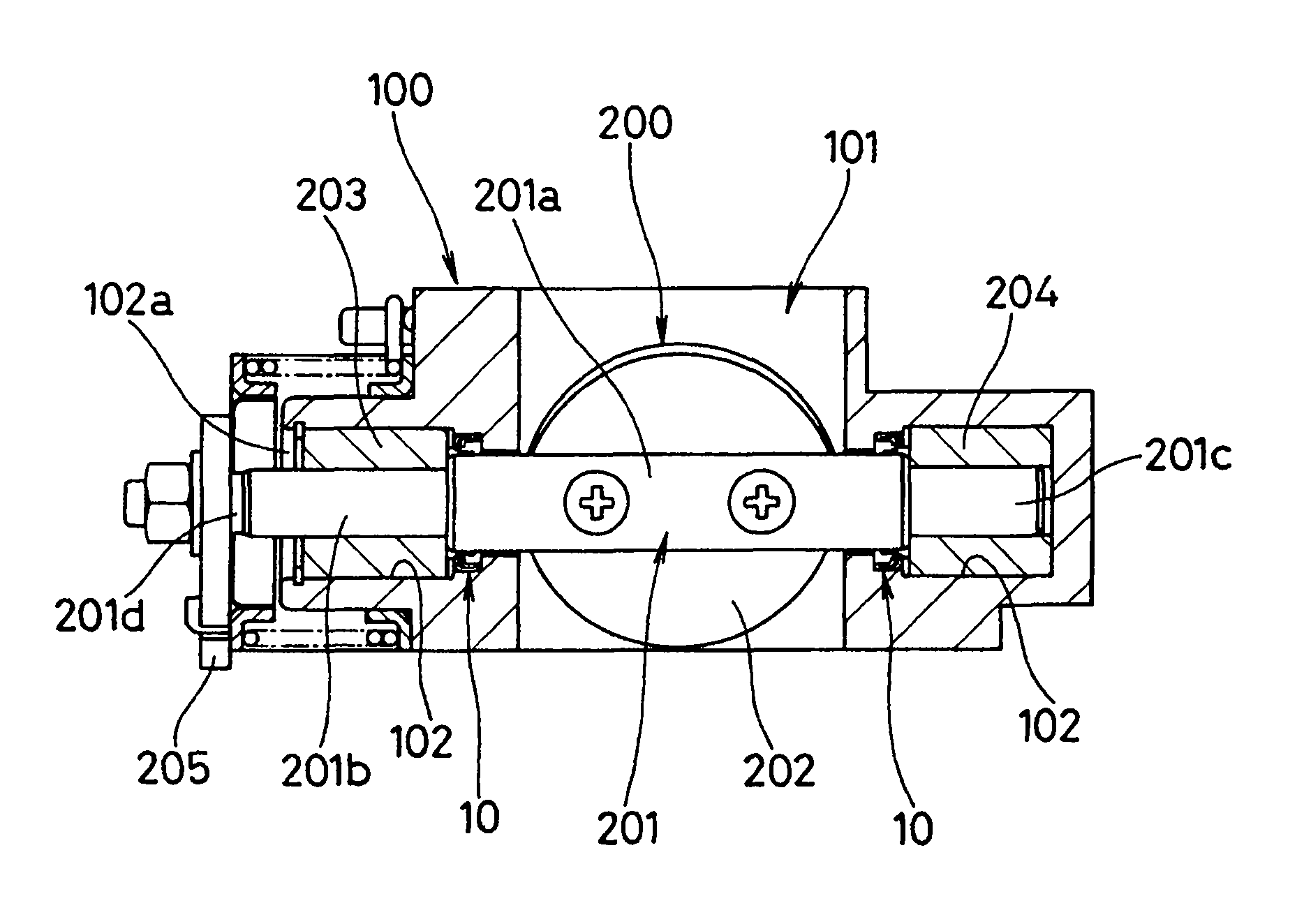

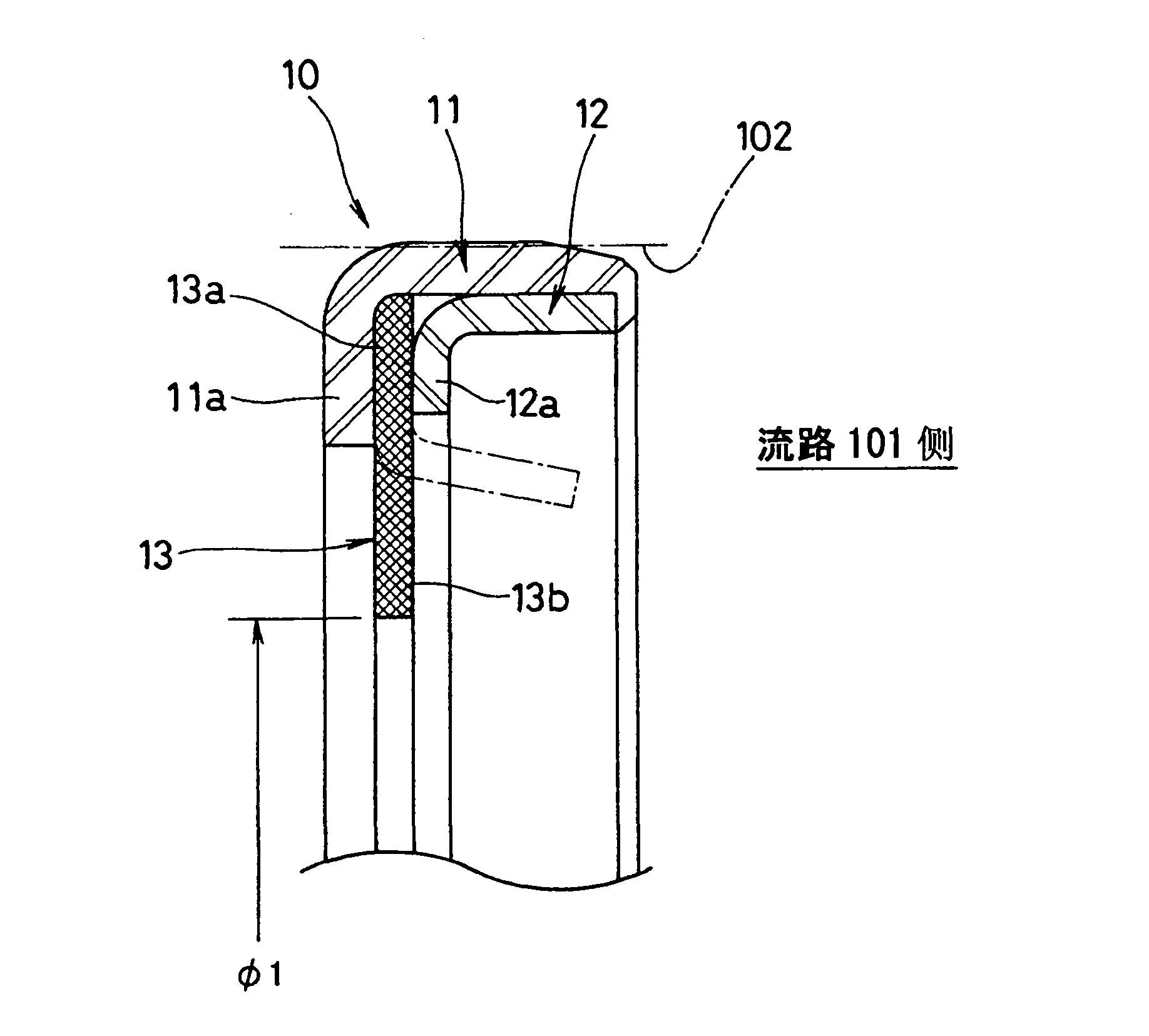

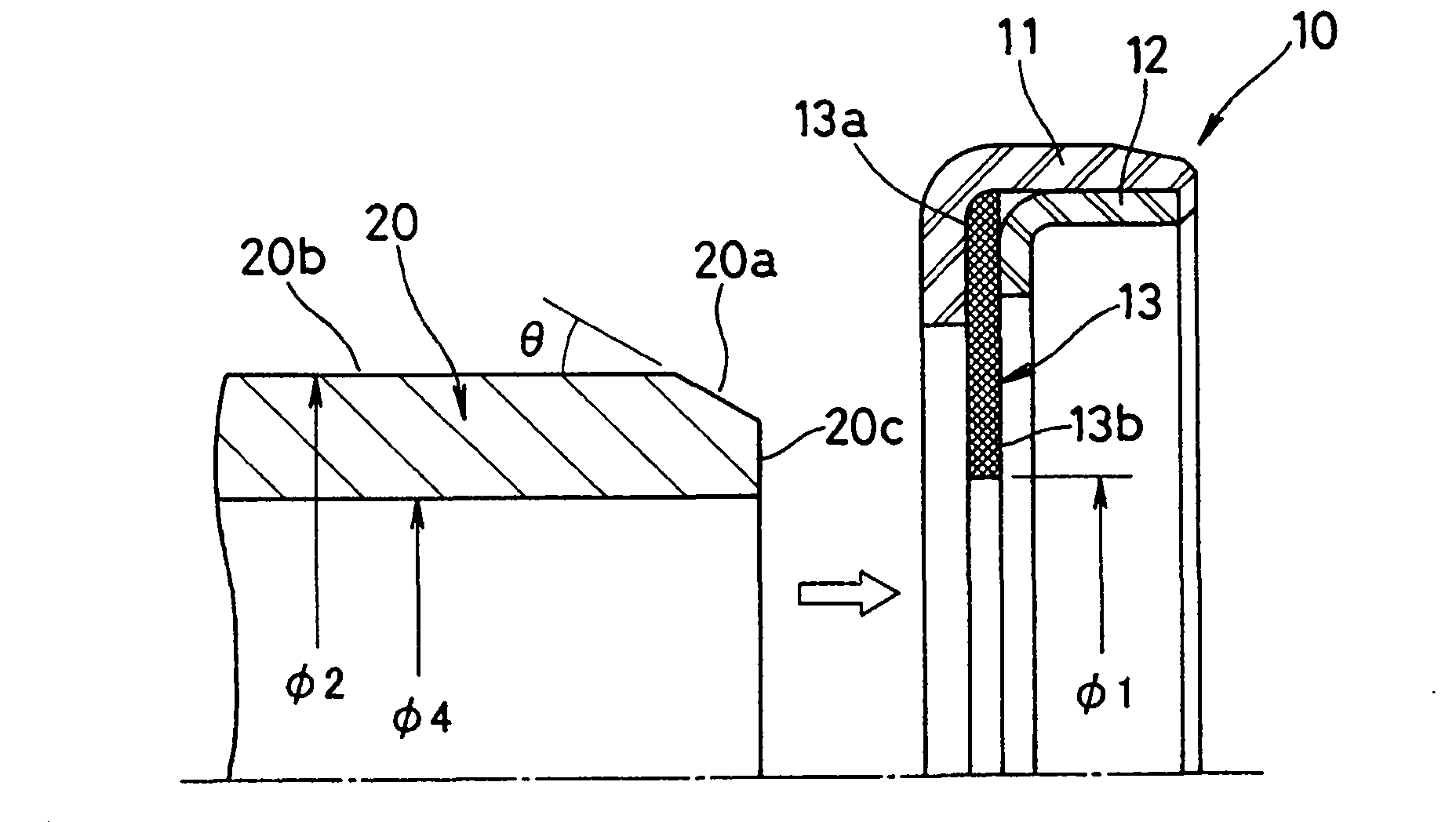

[0042] Preferred embodiments of the present invention will be described below with reference to the drawings. figure 1 It is an explanatory diagram showing the sealing device according to the present invention together with the valve assembly of the EGR system. figure 2 It is a sectional view of one side taken along a plane passing through the axis of the sealing device according to the present invention.

[0043] figure 1 The shown valve assembly includes: a housing 100 having a flow path 101 communicating with an exhaust manifold (not shown) and an intake manifold; and a butterfly valve 200 for adjusting the flow path cross-sectional area of the flow path 101 .

[0044] Butterfly valve 200 is equipped with: valve shaft 201, is opened on the housing 100 in the direction perpendicular to the center line of flow path 101, and it is inserted in the valve shaft insertion hole 102 that one end is closed; Bearing 203,204, in the Both sides of the flow path 101 support the valve

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap