Low pressure drop check valve

A check valve and low pressure drop technology, applied in the field of low pressure drop check valves, can solve the problems of high opening pressure, valve failure, large disc rotation radius, etc., and achieve the effect of good sealing performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

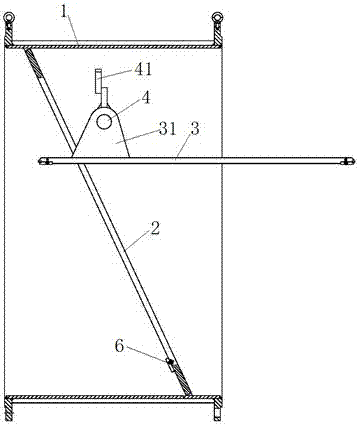

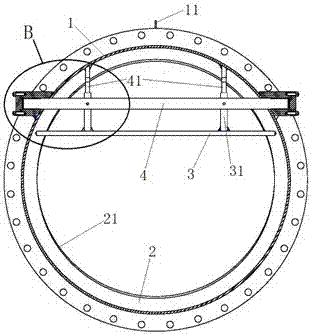

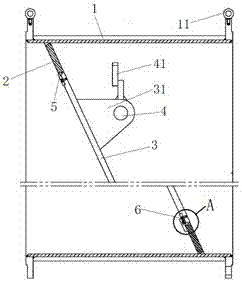

[0022] Such as Figure 1 to Figure 5 As shown, the embodiment of the present invention provides a low-pressure drop check valve, which includes a tubular valve body 1 and a valve disc 3. Flanges are respectively provided at the inlet and outlet of the valve body 1 to connect pipelines or other valves. The upper end of the flange is provided with a suspension ring 11, and one end of the upper surface of the valve disc 3 is provided with a lug 31, and the surrounding walls of the valve disc 3 are provided with a sealing groove, and a sealing ring 5 is provided in the sealing groove. In this embodiment , preferably, the lug 31 is arranged near the upper edge of the valve flap 3; the lug 31 is connected with the support rod 41 arranged on the upper wall of the inner cavity of the valve body 1 through the pin shaft 4 arranged horizontally, and the axis of the pin shaft 4 Vertical plane where the axis of the valve body 1 is located. In this embodiment, both ends of the pin shaft 4 pass

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap