Vacuum chamber negative pressure adjusting device and method for using same

A technology of regulating devices and vacuum chambers, which is applied in the direction of valve devices, valve details, valve lifts, etc., can solve the problems of not being able to achieve stable and adjustable dipping liquid level, explosion-proof, etc., and achieve adjustable dipping liquid level, stable dipping liquid level, The effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

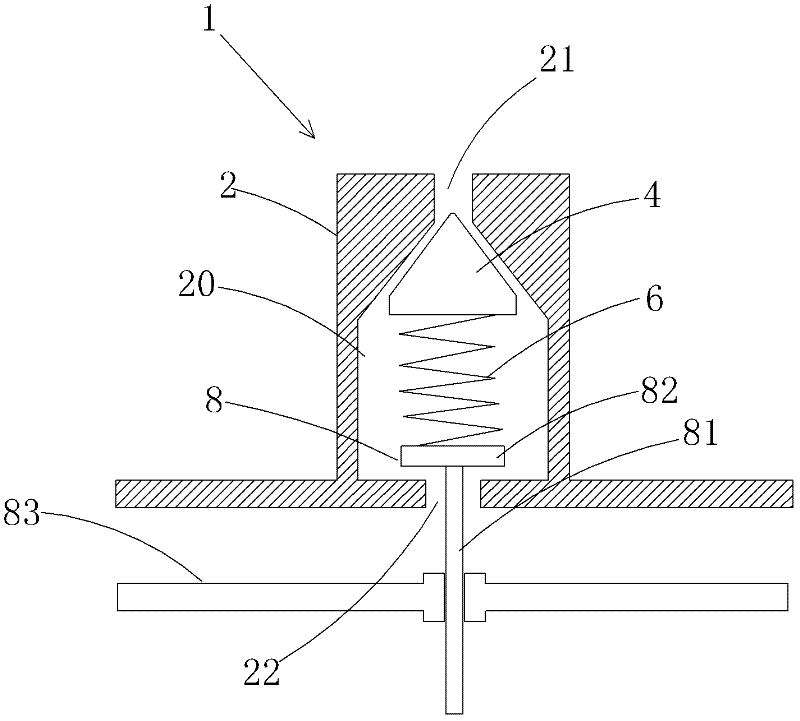

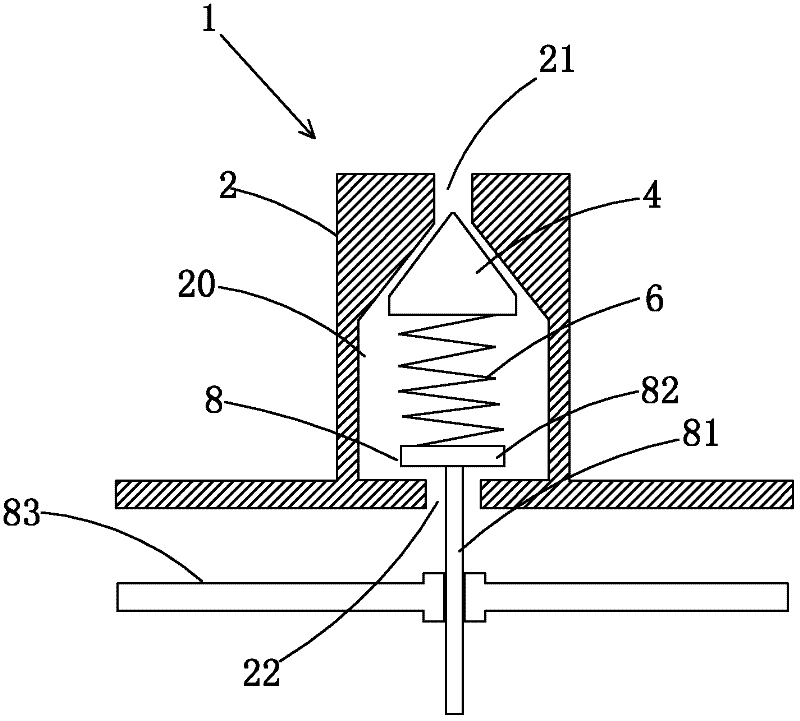

[0020] like figure 1 As shown, the vacuum chamber negative pressure regulating device 1 of the present invention comprises: a valve body 2 , a cone plug 4 arranged in the inner cavity 20 of the valve body 2 , a spring 6 , and a sealing sliding rod 8 movably connected to the lower end of the valve body 2 , the top of the inner cavity 20 of the valve body 2 is matched with the conical surface of the cone plug 4, the upper end of the valve body 2 is provided with a hole groove 21 that runs through the top of its inner cavity 20, and the lower end of the valve body 2 is provided with a through hole 22 that communicates with its inner cavity 20, One end of the sealing slide rod 8 enters the inner cavity 20 of the valve body 2 through the through hole 22, and is connected to the taper plug 4 through the spring 6. The through hole 22, the inner cavity 20 and the hole groove 21 are successively connected to form a communication channel. , through the sealing sliding rod 8 moving up and d

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap