Structure of push-and-pull fan made of composite material

A composite material and longitudinal axis technology, which is applied to the layout of the wings, the frame of the wings, and building components, etc., can solve the problems of insufficient wind pressure resistance and airtightness, and achieve good general performance of the window sash, beautiful functions, and low consumables Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

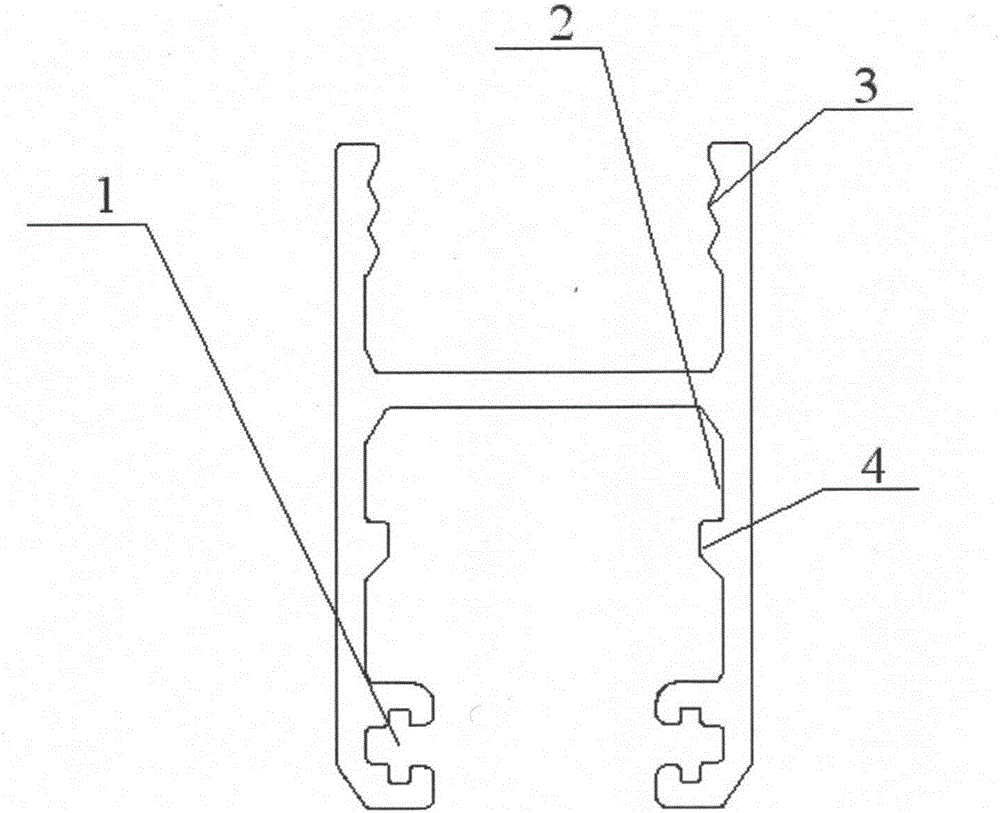

[0018] The present invention is a structure of a composite push-pull fan, such as figure 1 As shown, its cross-section is a simple "H"-shaped structure, including two opposite longitudinal axes and a transverse axis connected therebetween. Both inner sides of one end of the "H"-shaped structural profile are provided with brush grooves 1 for placing brush seals 14, and both inner sides of the other end of the "H"-shaped structure are provided with tooth grooves 3 for fixing glass 13. One end of the "H"-shaped structure is provided with a functional groove 2 at a position away from the brush groove 1. The functional groove 2 is formed by a horizontal axis and protrusions 4 on two longitudinal axes. The angle between one side of the protrusion 4 located in the functional groove 2 and the longitudinal axis is less than or equal to 90°, and the angle between the other side of the protrusion 4 and the longitudinal axis is greater than 90°.

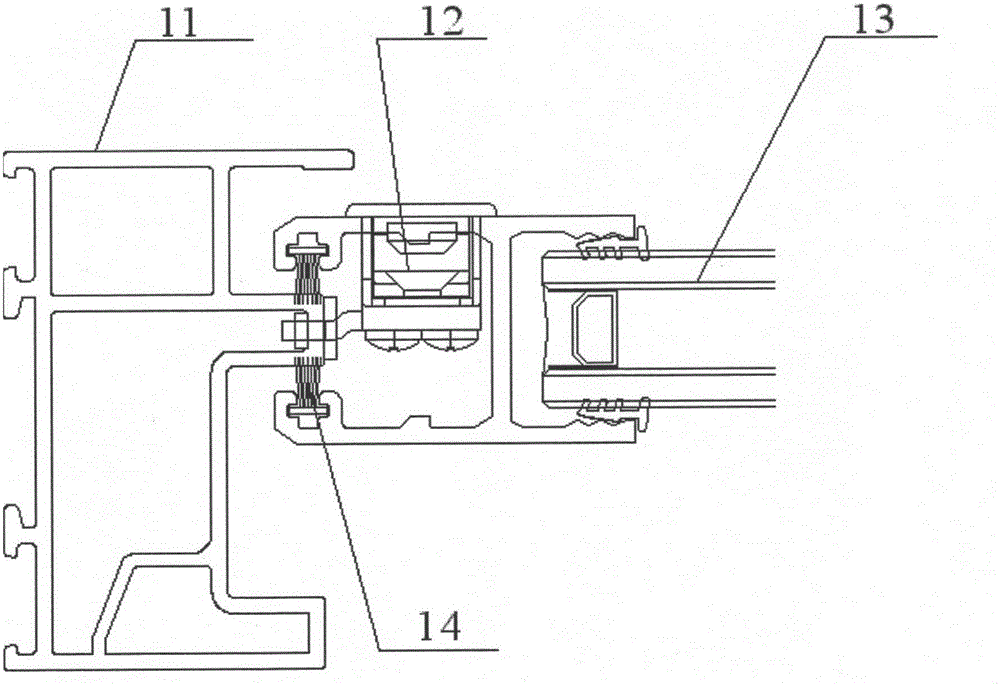

[0019] Such as figure 2 Shown, two hairb

Embodiment 2

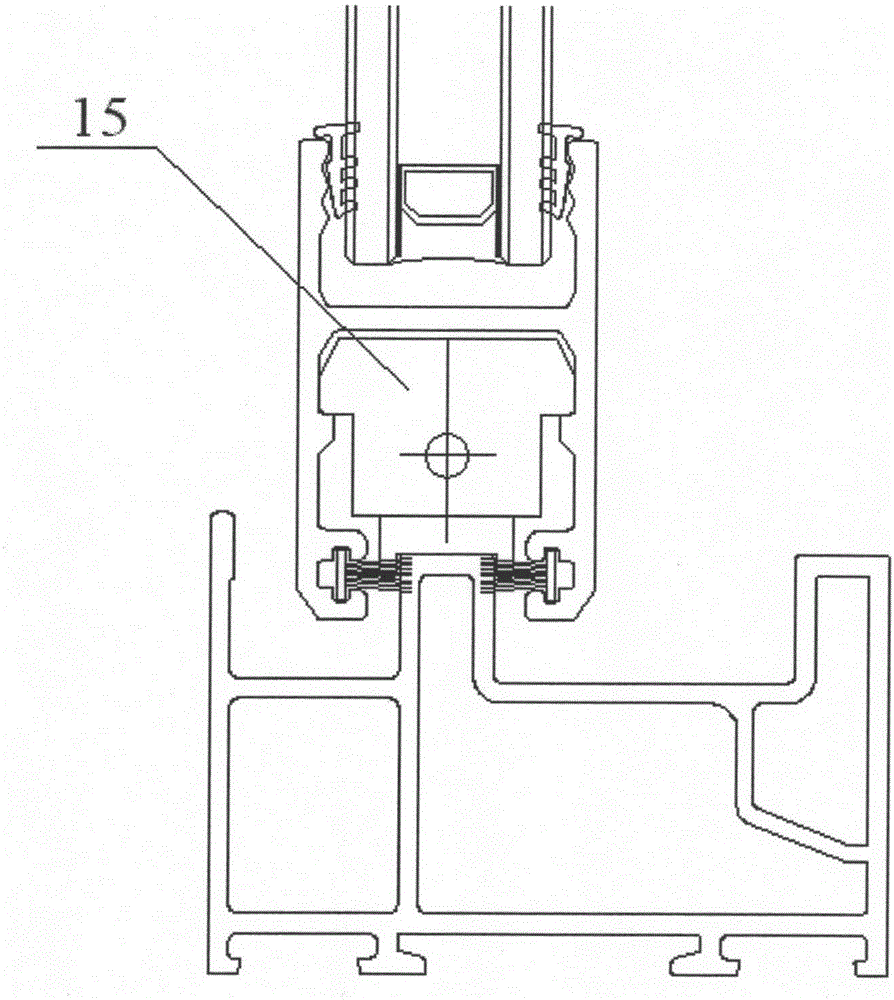

[0023] Such as image 3 Shown, two hairbrush grooves 1 of the present invention are all loaded onto hairbrush sealing strip 14, and the sealing between the hairbrush sealing strip 14 and the outer frame 11 of sliding window plays whole window sealing. A pulley 15 can be installed on the functional groove 2, so that the push-pull fan can move in the outer frame 11 through the pulley 15, and the sealing of the tooth groove 3 and the glass 13 can be inlaid and connected with a special sealing rubber strip or sealant.

[0024] Others are the same as in Example 1.

Embodiment 3

[0026] Such as Figure 4 As shown, in the functional groove 2, a fan connecting piece 16 can be installed, and a circle of the fan is assembled into one body through the fan connecting piece 16, and the tooth groove 3 and the glass 13 are hermetically connected.

[0027] Others are the same as in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap