Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Dead weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

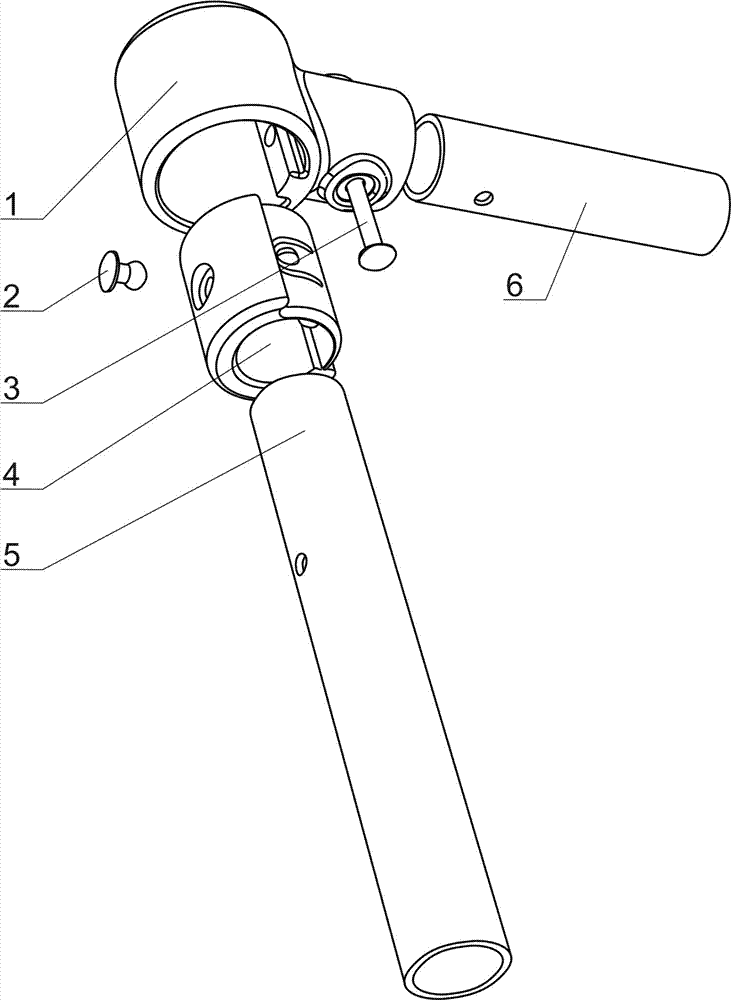

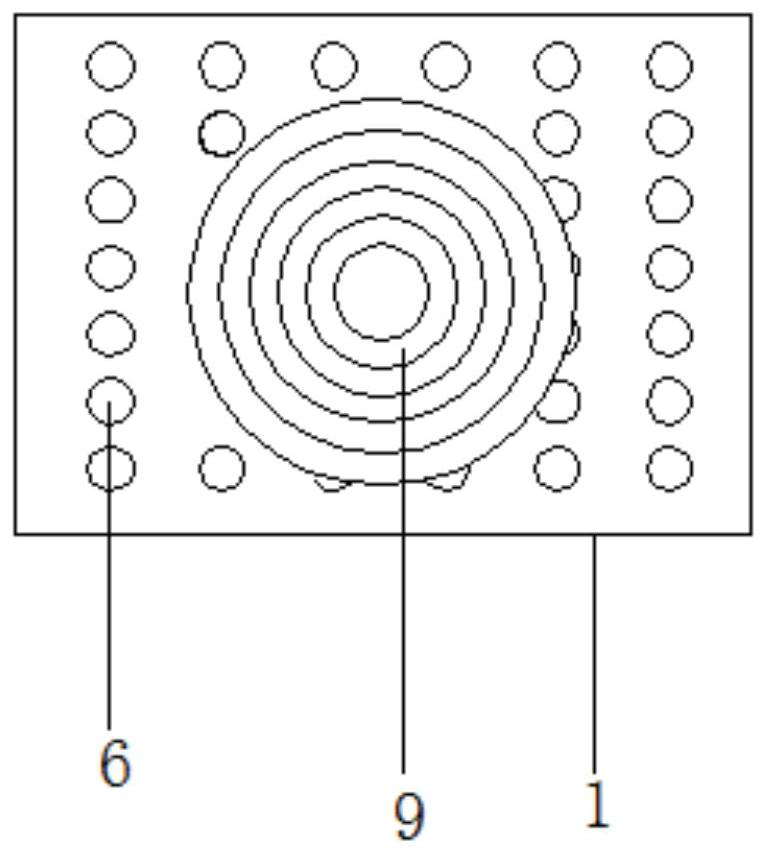

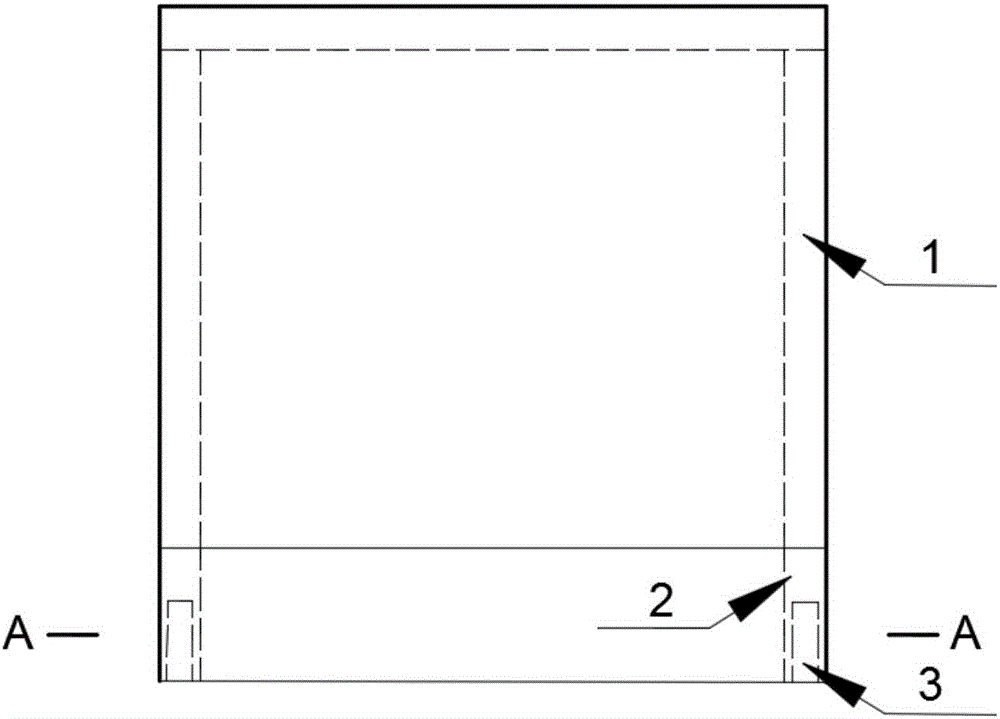

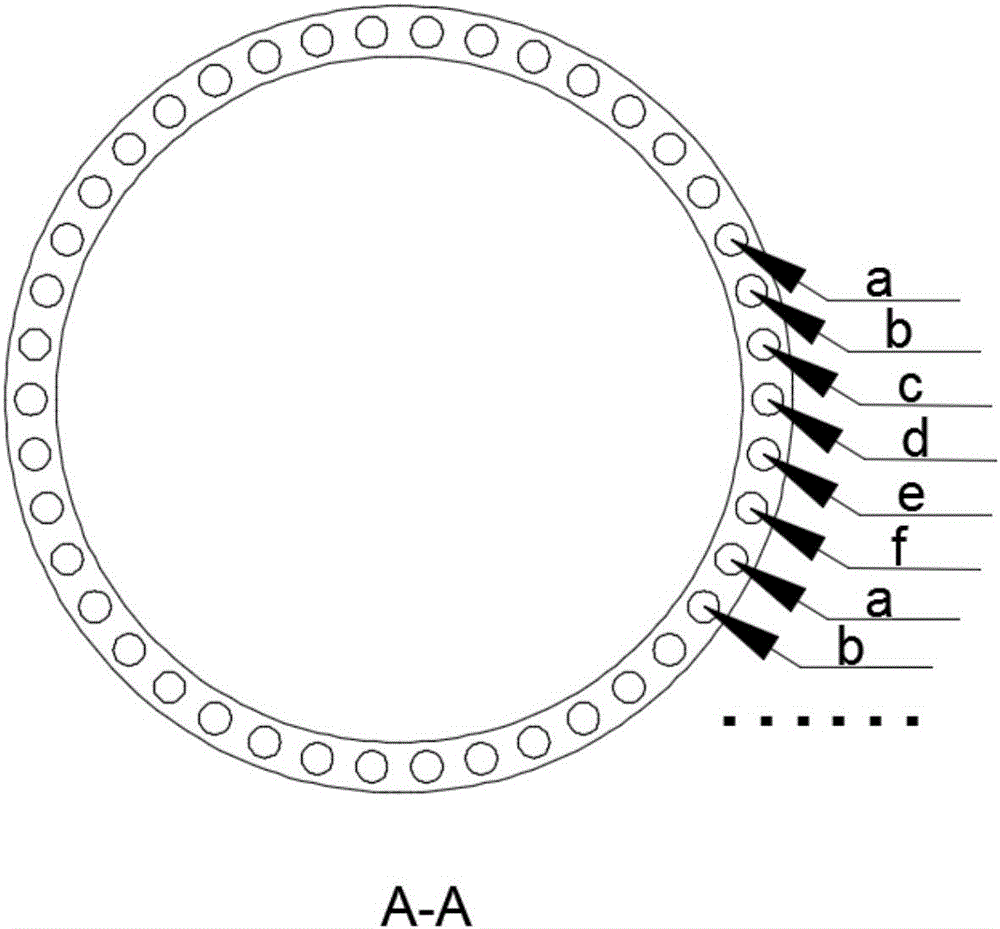

Compression braking device of four-stroke cycle internal combustion engine

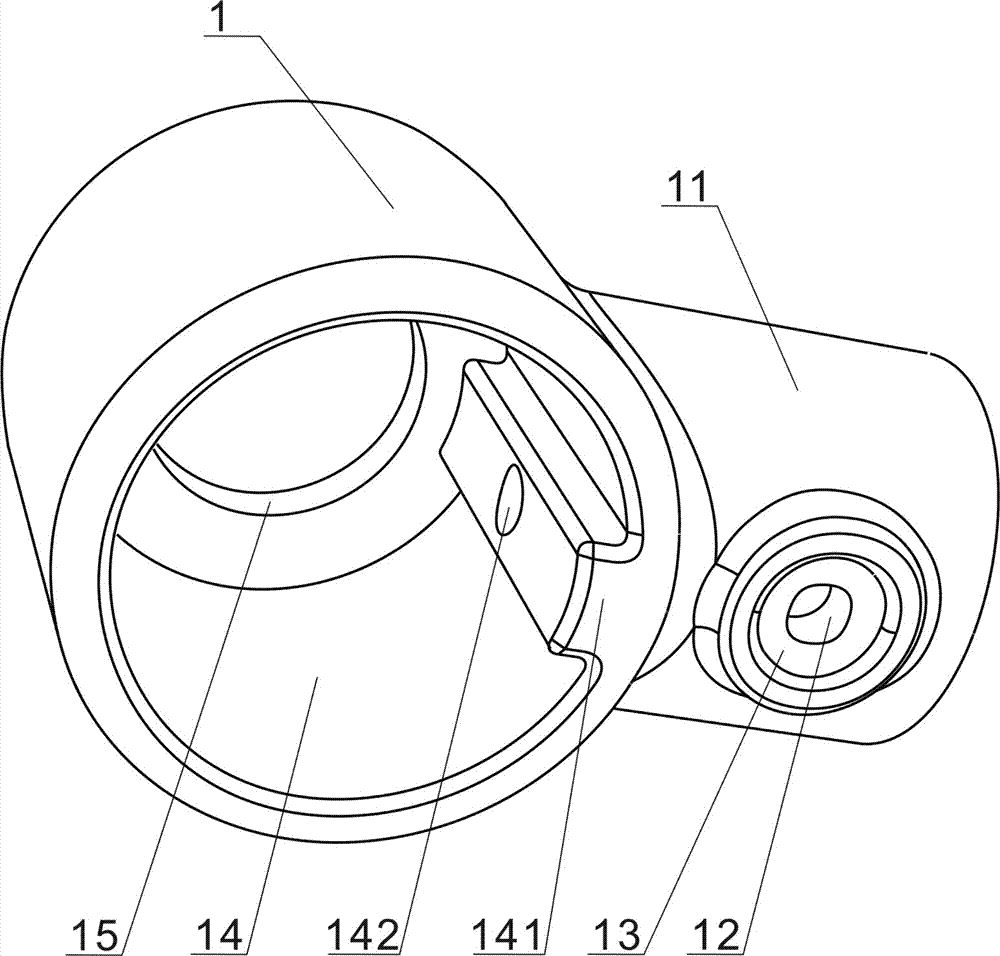

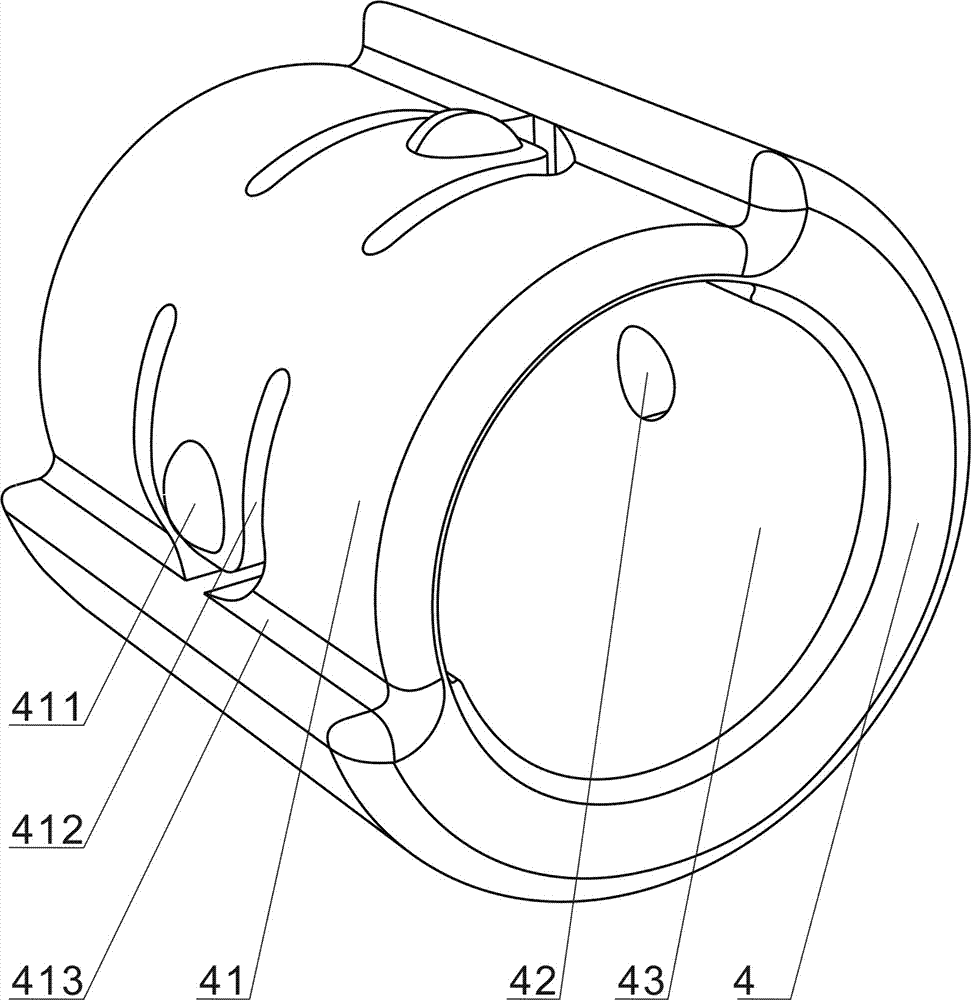

ActiveCN101526018AAchieve the purpose of brake assistIncrease stiffnessValve arrangementsOutput powerExhaust valveSpring force

The invention provides a compression braking device of a four-stroke cycle internal combustion engine. A control valve mechanism (13) and a clearance compensation mechanism (23) with the compensated clearance being the lift range of a braking projection are installed in parallel on one end of an amounting elephant feet of a rocker (3); a clearance compensation mechanism (11) with the compensated clearance being the lift range of a valve clearance is arranged in the midpoint of the connecting positions of an exhaust valve bridge (5) and two exhaust valves (6); the elephant feet (24) are coaxially connected below the lower end of the previous clearance compensation mechanism (23); the upper end of the next clearance compensation mechanism (11) is always in contact with the lower ends of the elephant feet; and the spring force of the clearance compensation mechanism is smaller than braking oil pressure and larger than dead weight of the elephant feet. Compared with the prior art, the compression braking device improves the reliability and the balance of a valve actuating mechanism, simplifies the structure, reduces the processing difficulty of the rocker, improves the rigidity of the rocker, and improves the accuracy and operability of the adjustment of the valve clearance. In addition, when the engine compresses and brakes, the two exhaust valves can be opened at the same time, thereby improving the braking effect of the engine.

Owner:ZHEJIANG LIMING INTELLIGENT MFG CO LTD

Method for preparing insulator

Owner:STATE GRID CORP OF CHINA +1

Method for reducing unevenness of composite stainless steel plates in manufacturing composite steel plates

Owner:TAIYUAN IRON & STEEL GROUP

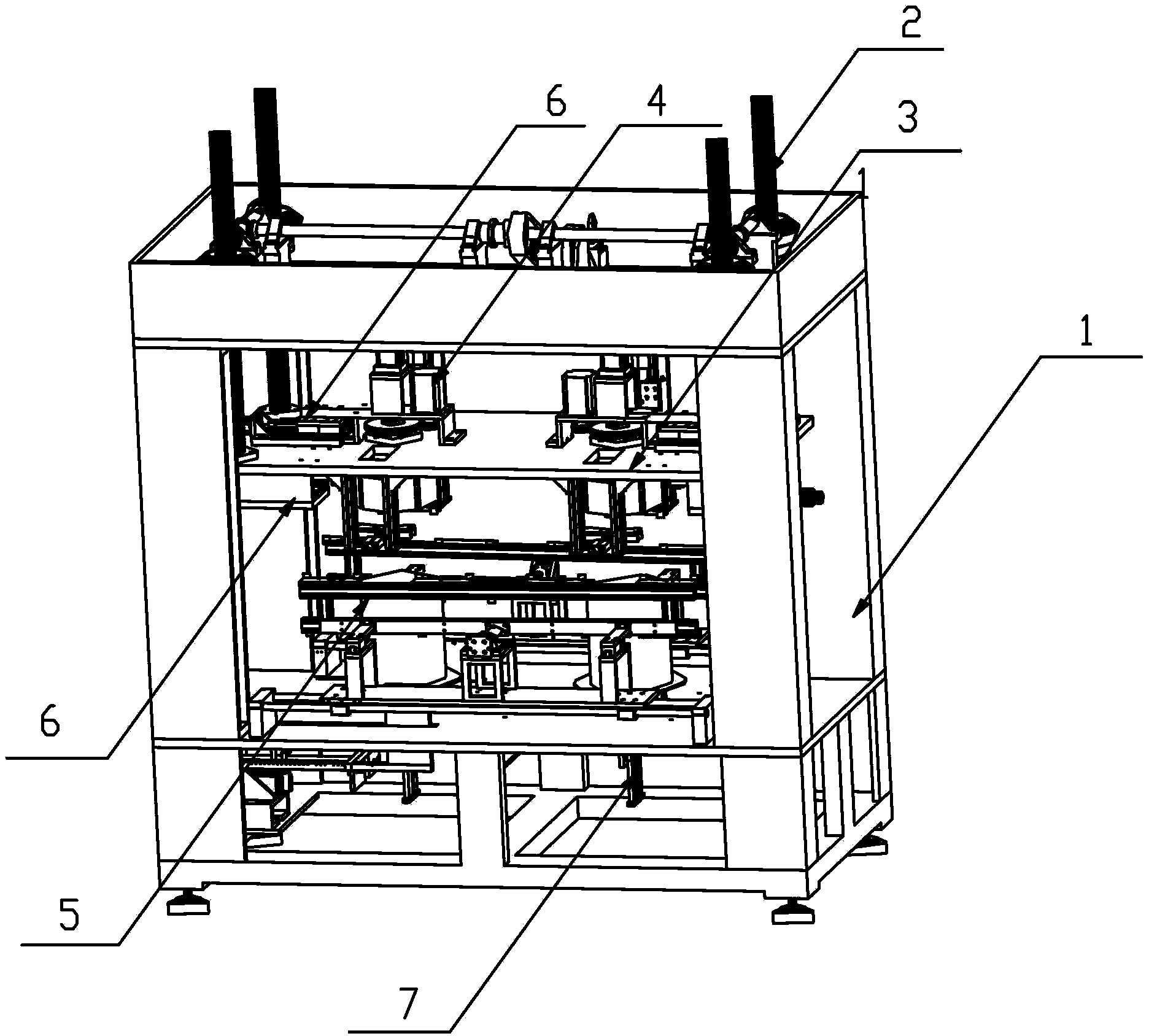

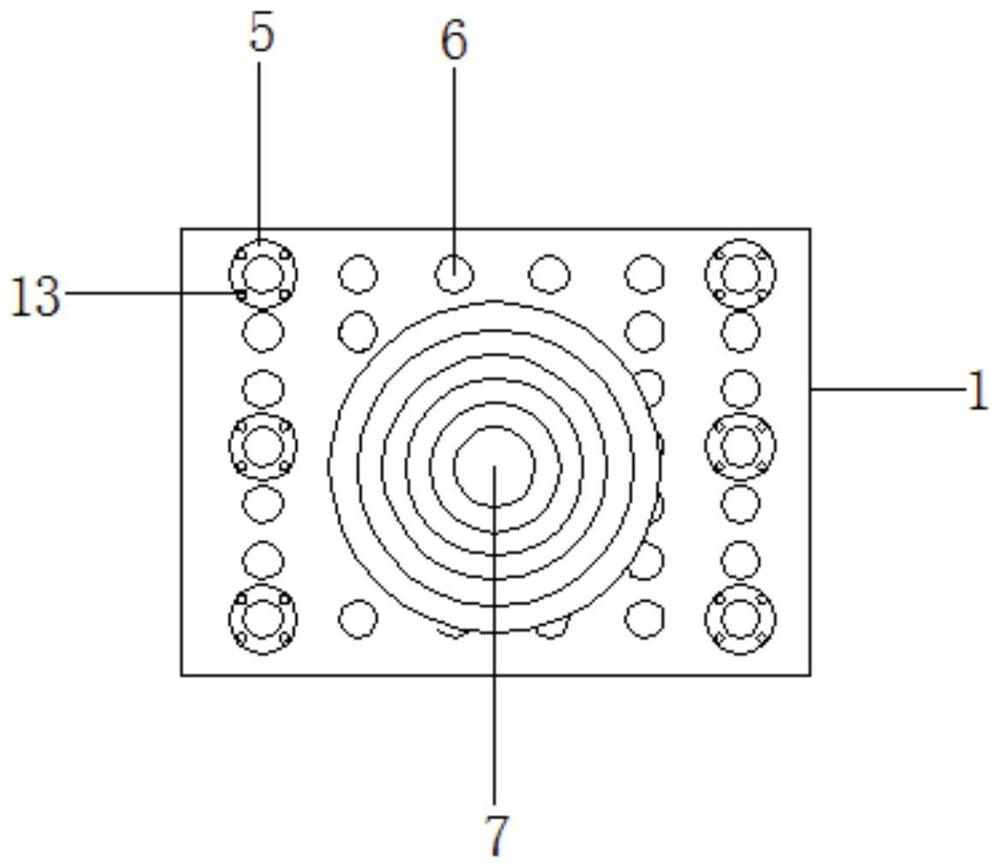

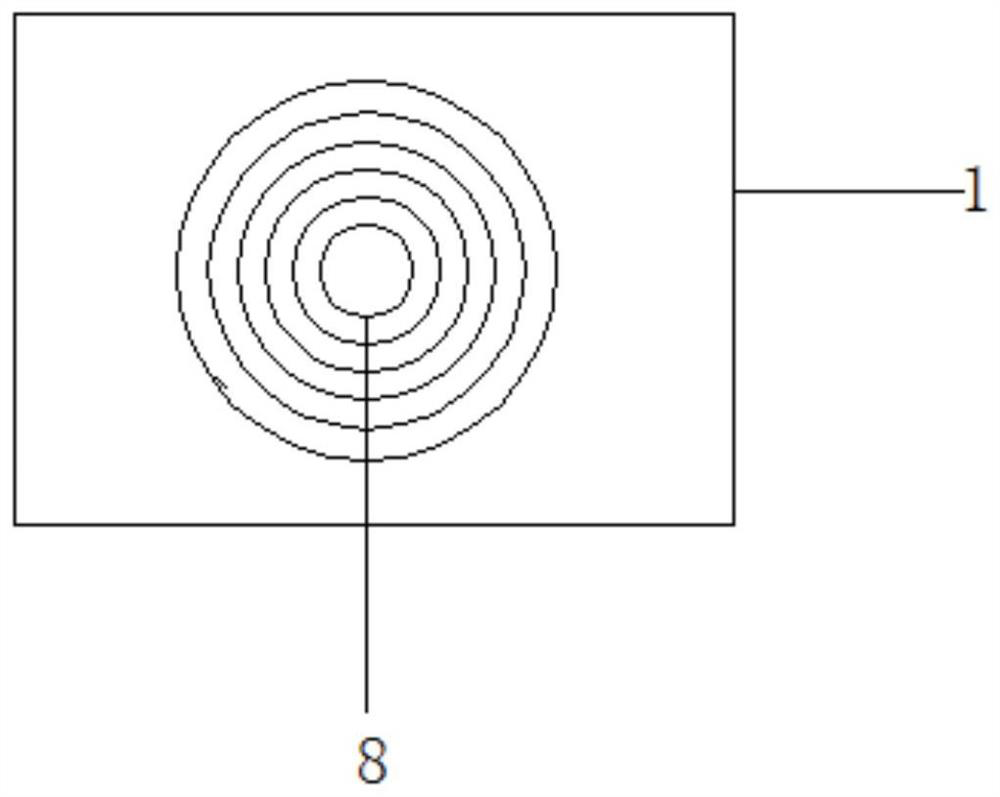

Rewinding machine with surface drive function

InactiveCN106006146AGuaranteed bulkinessIncrease intake pressureWebs handlingElectric machineEngineering

The invention discloses a rewinding machine with a surface drive function, and belongs to the technical field of printing machinery. According to the rewinding machine, a paper rewinding tension detection device is arranged on a paper output channel behind a traction unit; the paper rewinding tension detection device comprises a second swinging rod; one end of the second swinging rod is connected with a floating roll, and a second sensor for detecting a rotating position of the second swinging rod is arranged at the other end of the second swinging rod; a rewinding roll driven through a second variable-frequency motor behind the paper rewinding tension detection device is arranged, and the second variable-frequency motor is connected with the second sensor through a controller; an inflatable shaft for installing a paper reel in a penetrating manner is arranged above the rewinding roll, and in transmission connection with a lifting cylinder controlled by a proportional electromagnetic valve; and the proportional electromagnetic valve is connected with a third sensor for detecting a lifting position of the inflatable shaft through the controller. According to the rewinding machine disclosed by the invention, the problems that an original bulkiness of a printing stock cannot be recovered due to a too high tension during rewinding of an existing rewinding machine, and material reels are tight outside and loose inside due to dead weights can be solved.

Owner:王金根 +1

Edge spinning machine

Owner:正太控股(广东)有限公司

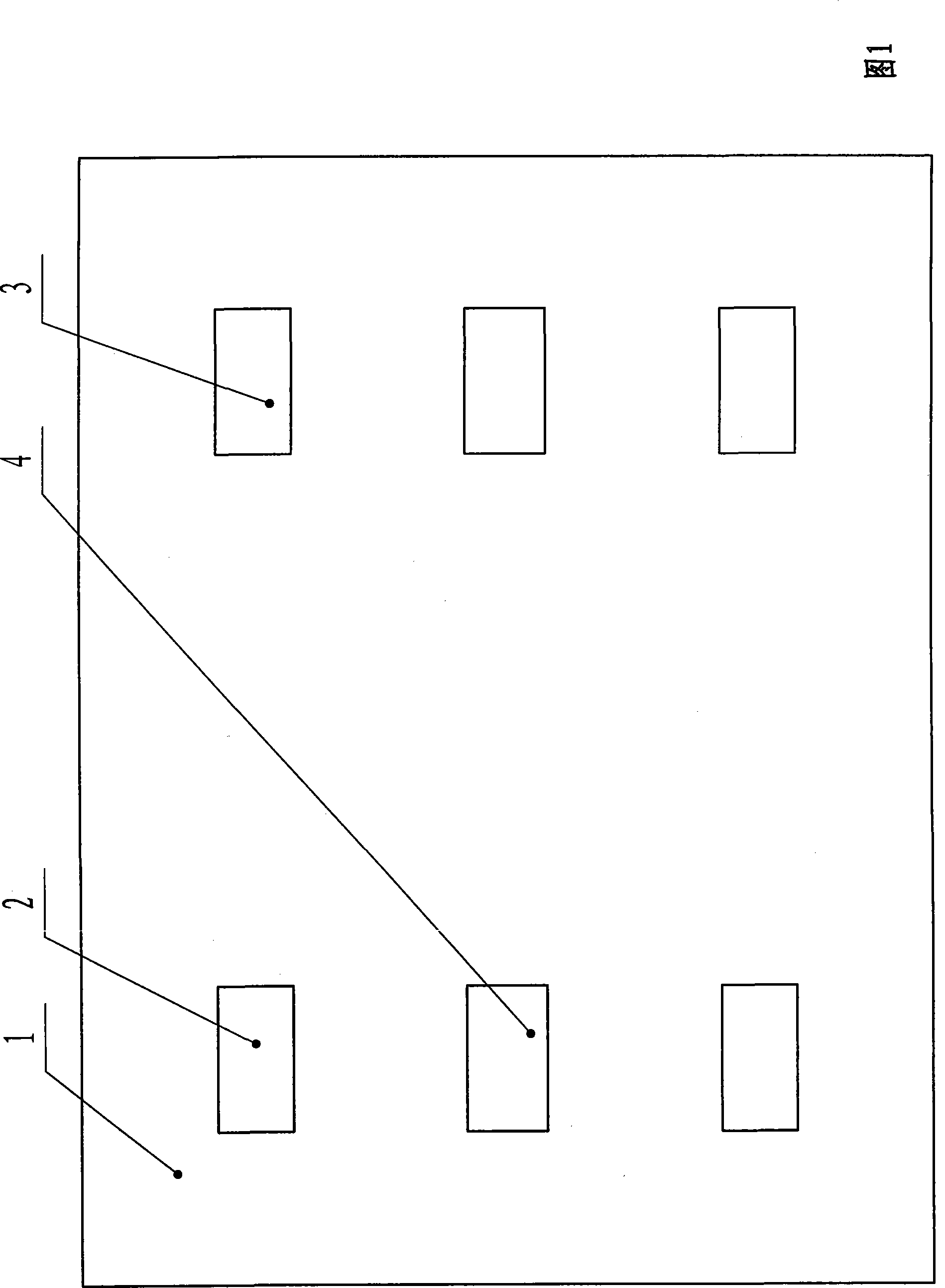

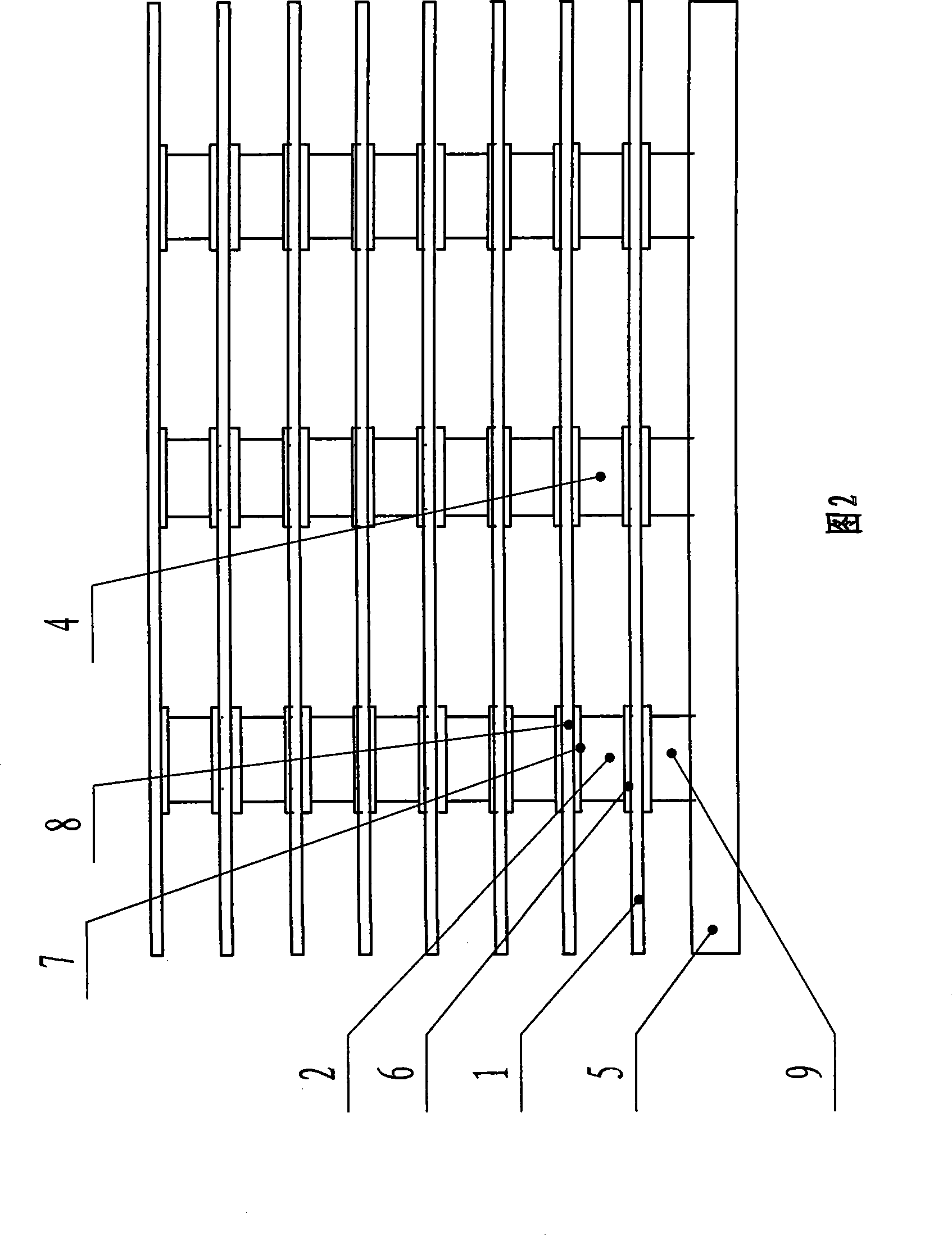

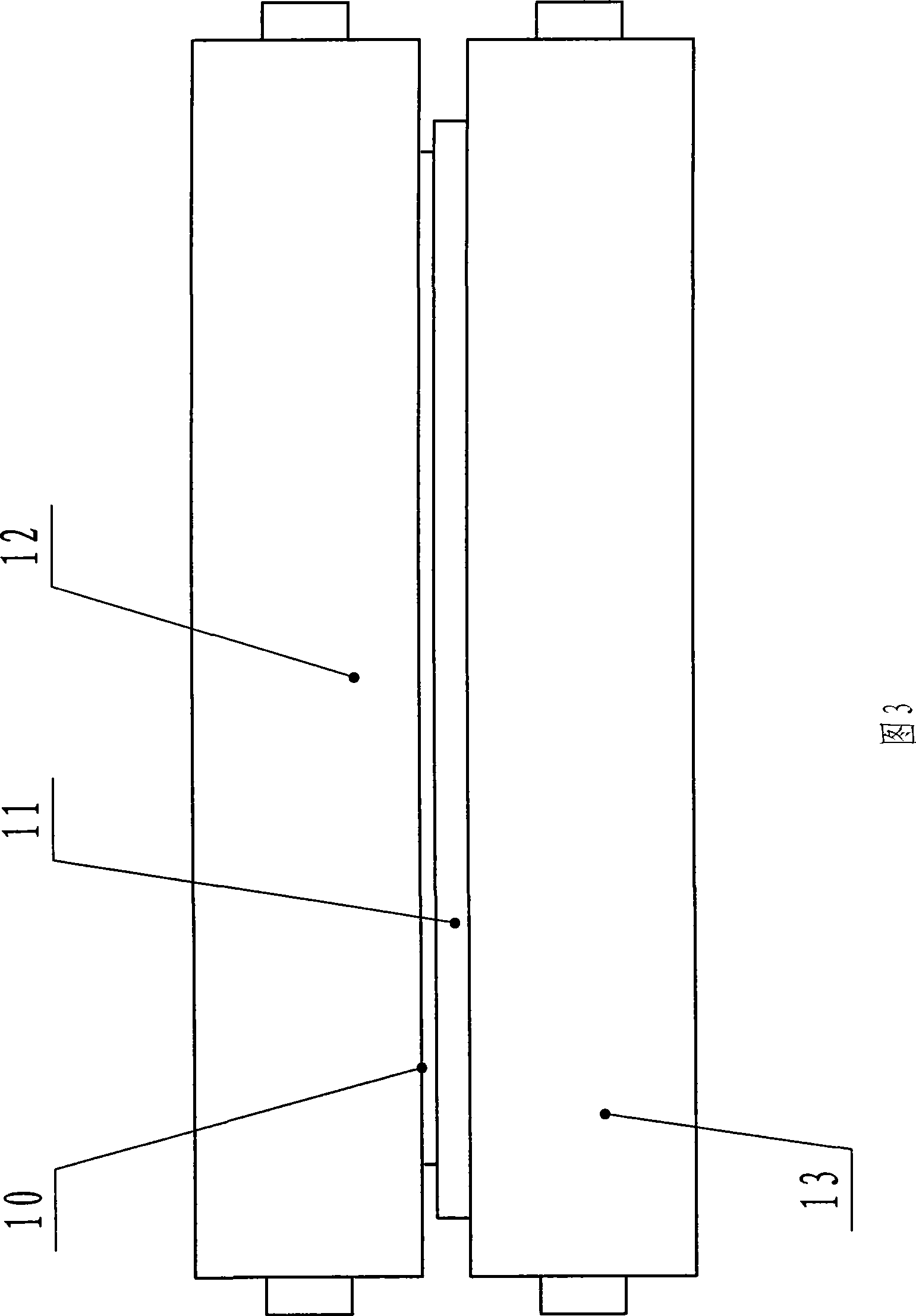

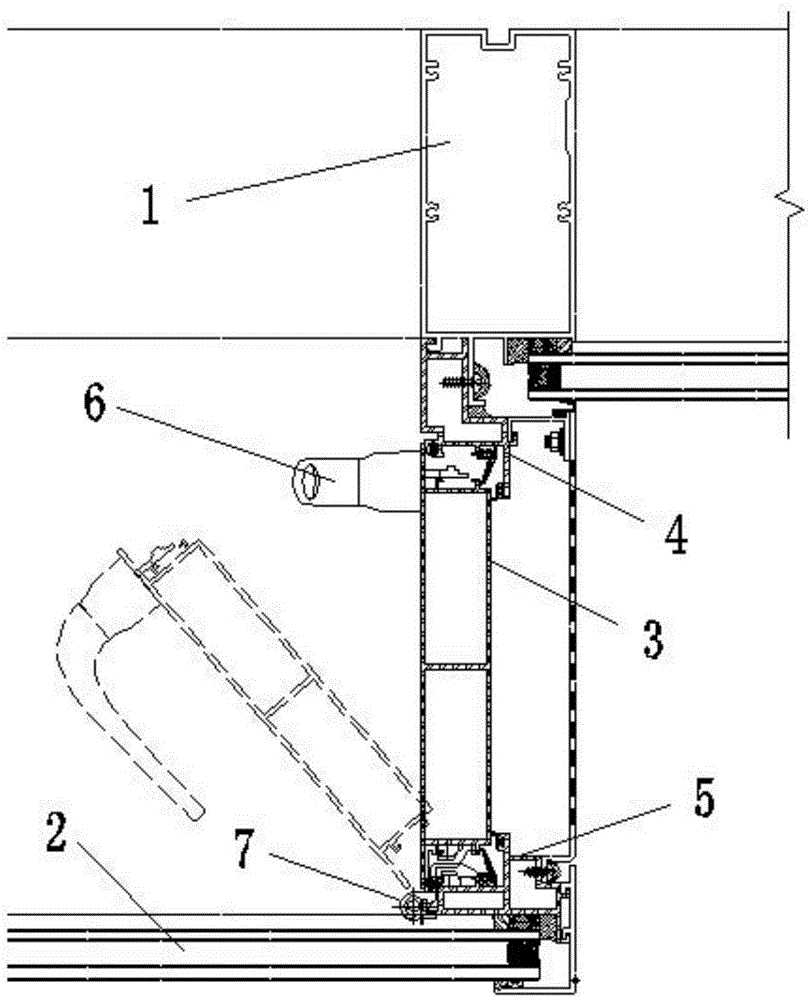

Casement window structure in unit curtain wall

Owner:SUZHOU GOLD MANTIS CURTAIN WALL CO LTD

Pipe fitting rotating device

Owner:郑雪峰

Spiral hollow brick screen design structure

Owner:GOLD MANTIS CONSTR DECORATION

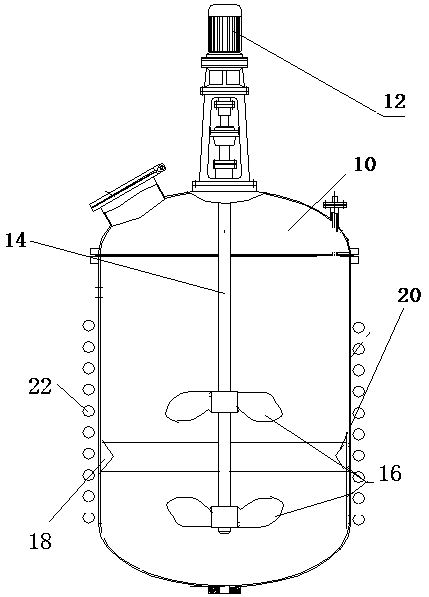

Reaction kettle

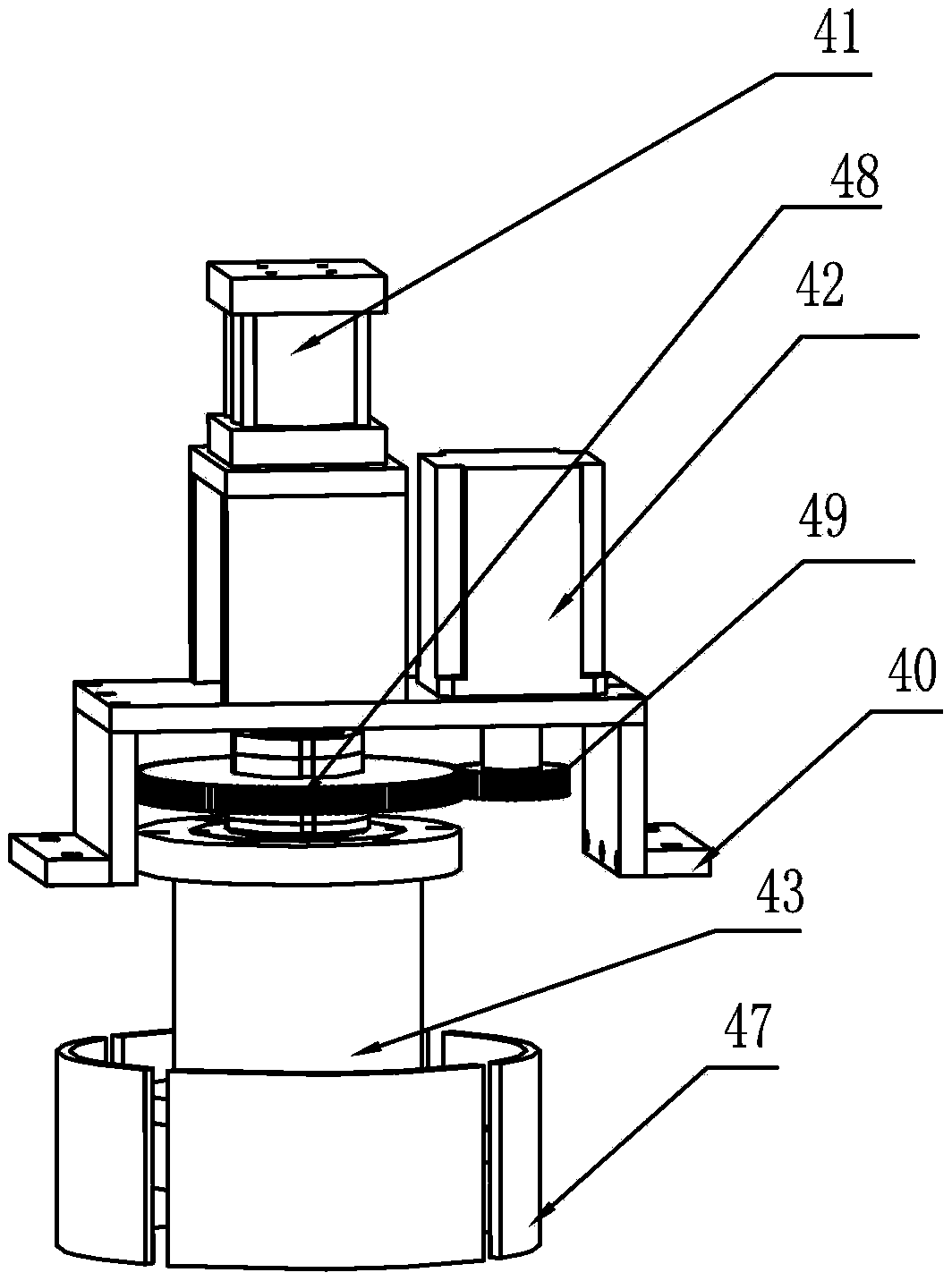

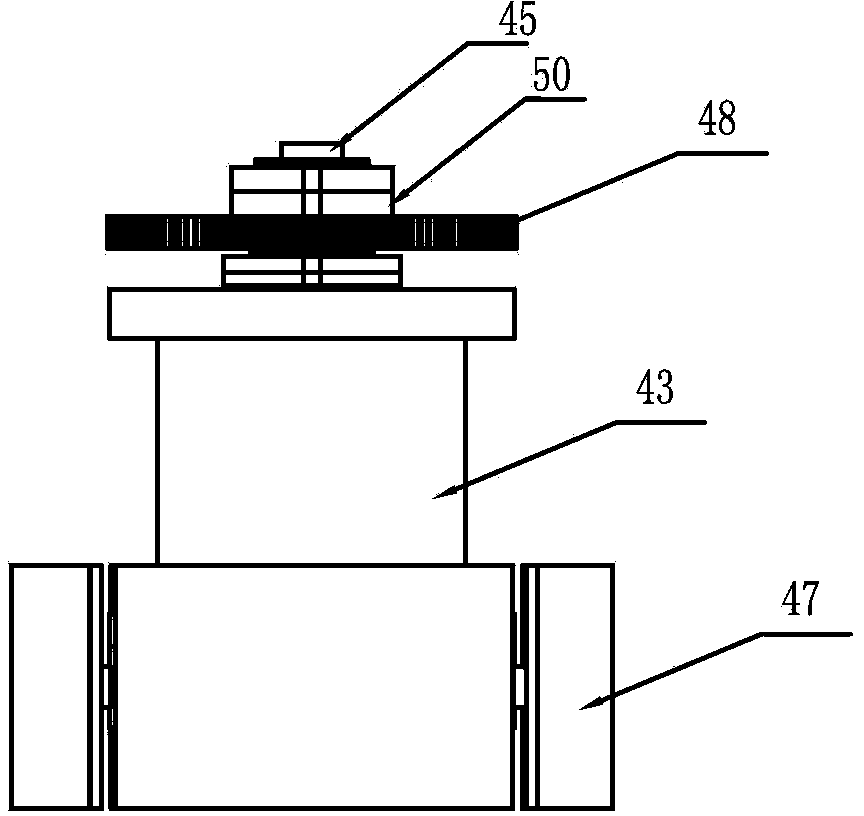

InactiveCN108554348AReduce wearFull mixing and stirring functionChemical/physical/physico-chemical stationary reactorsRotational axisElectric machinery

Owner:SUZHOU JINXIANG TITANIUM EQUIP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap