Flow guiding disc of group injection flow complemented-burning type gas burner

A gas burner and a deflector technology, which is applied in the directions of gas fuel burners, burners, combustion methods, etc., can solve the problems of asynchronous mixed combustion of gas and oxygen, low combustion thermal efficiency of blast gas burners, etc., and achieves a simple structure. , reducing emissions, the effect of sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

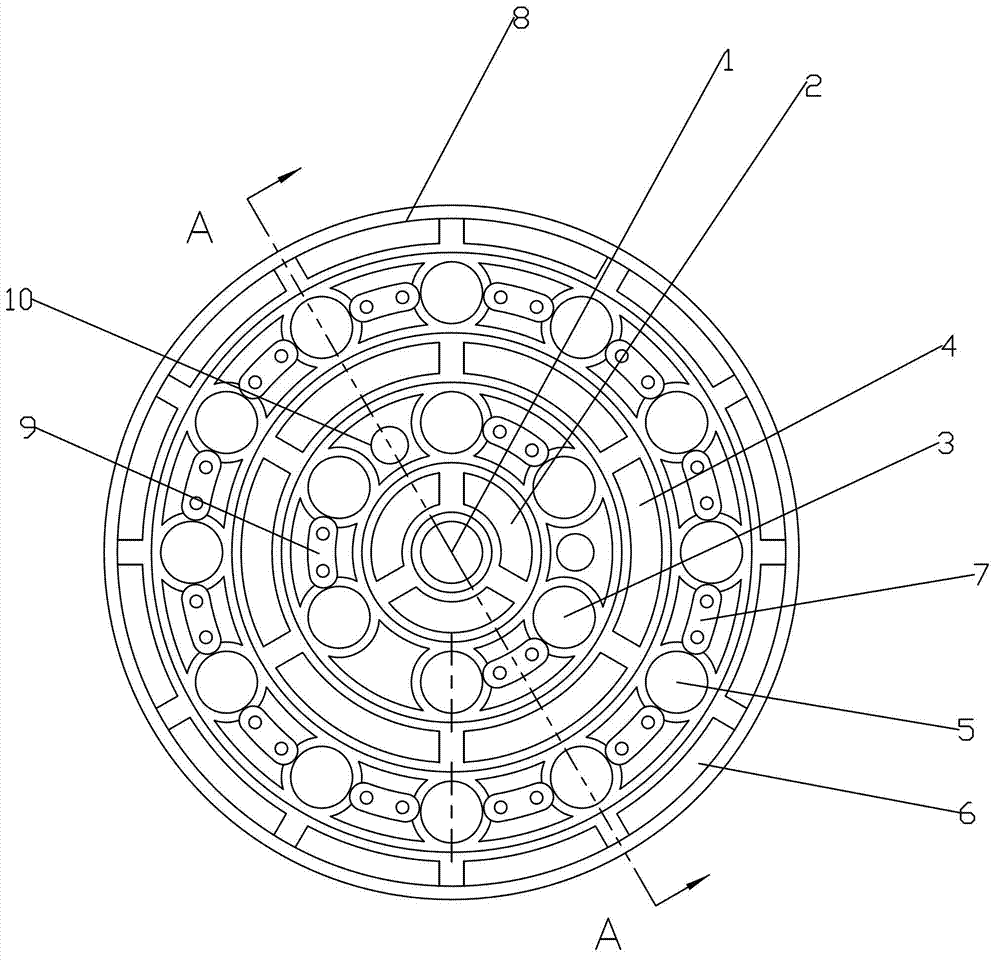

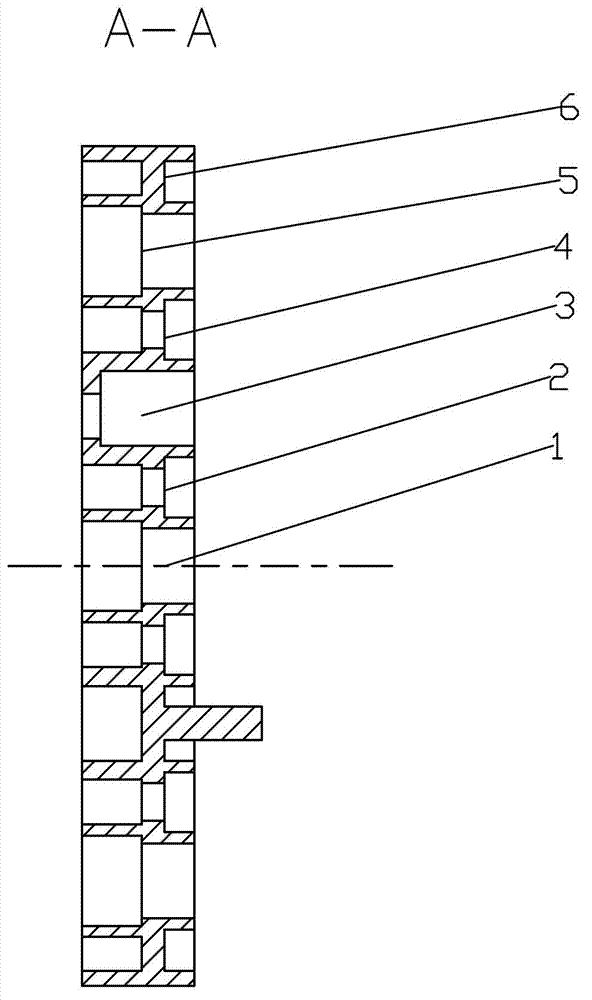

[0014] Such as Figure 1~2 As shown, the present invention includes a disc body 8, the center of the disc body 8 is provided with a main combustion small fire passage 1, and the outer ring of the main combustion small fire passage 1 is provided with three fan-shaped supplementary combustion small fire passages 2, and three supplementary combustion small fire passages 2 are provided. The small fire channels 2 are evenly distributed around the center of the disc body 1. The outer ring of the supplementary combustion small fire channel 2 is provided with six circular main combustion medium fire channels 3, and the six main combustion medium fire channels 3 are evenly distributed around the center of the disc body 1. Three inner ring supplementary combustion fire pillars 9 and two mounting holes 10 are arranged between the six main combustion intermediate fi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap