Low Profile Compressor Bleed Air-Oil Coolers

a compressor and air-oil cooler technology, applied in the direction of machines/engines, efficient propulsion technologies, mechanical equipment, etc., can solve the problems of affecting the design of small core engines, affecting the overall thrust output of the engine, and adding undesirable weight to the small core engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

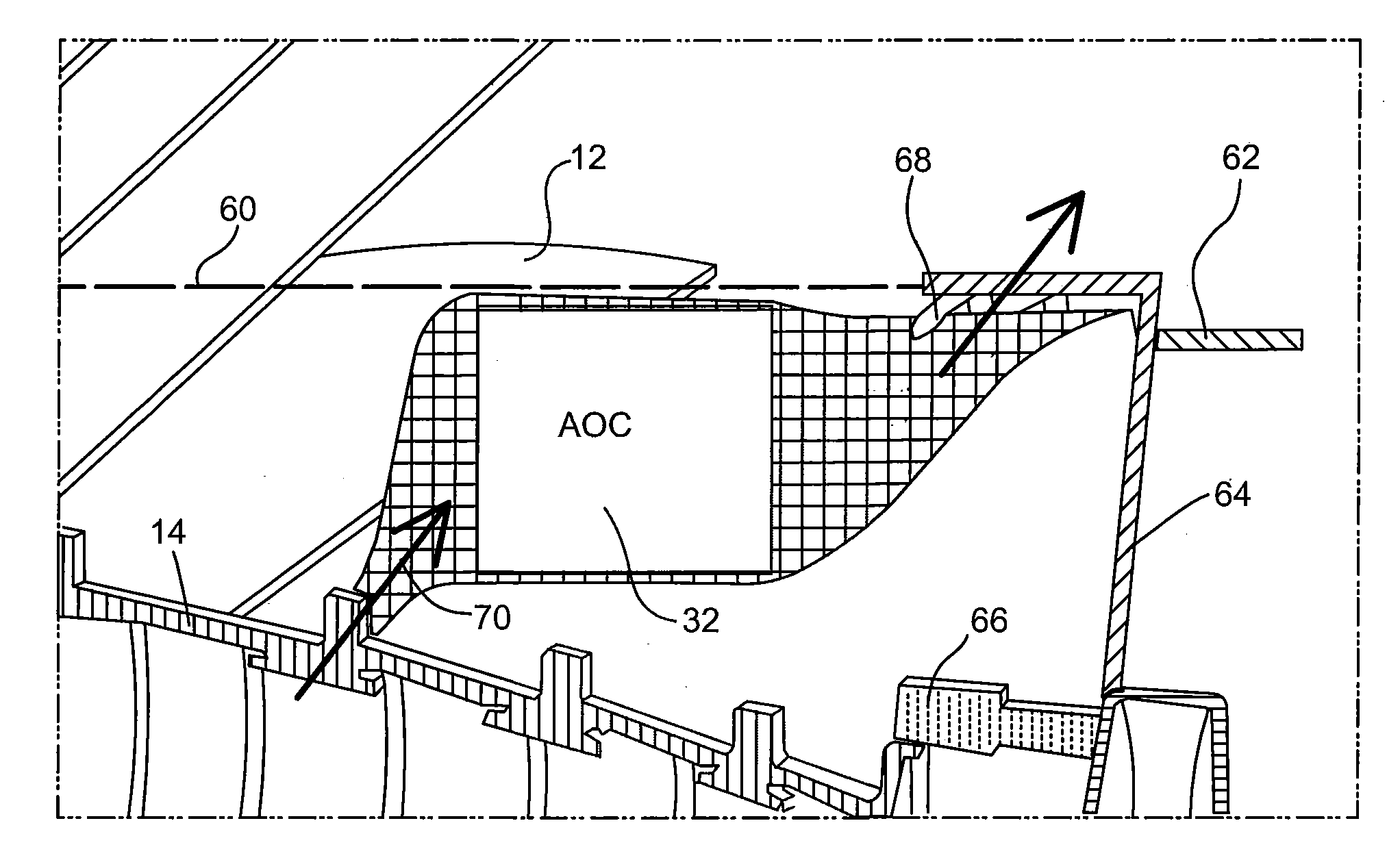

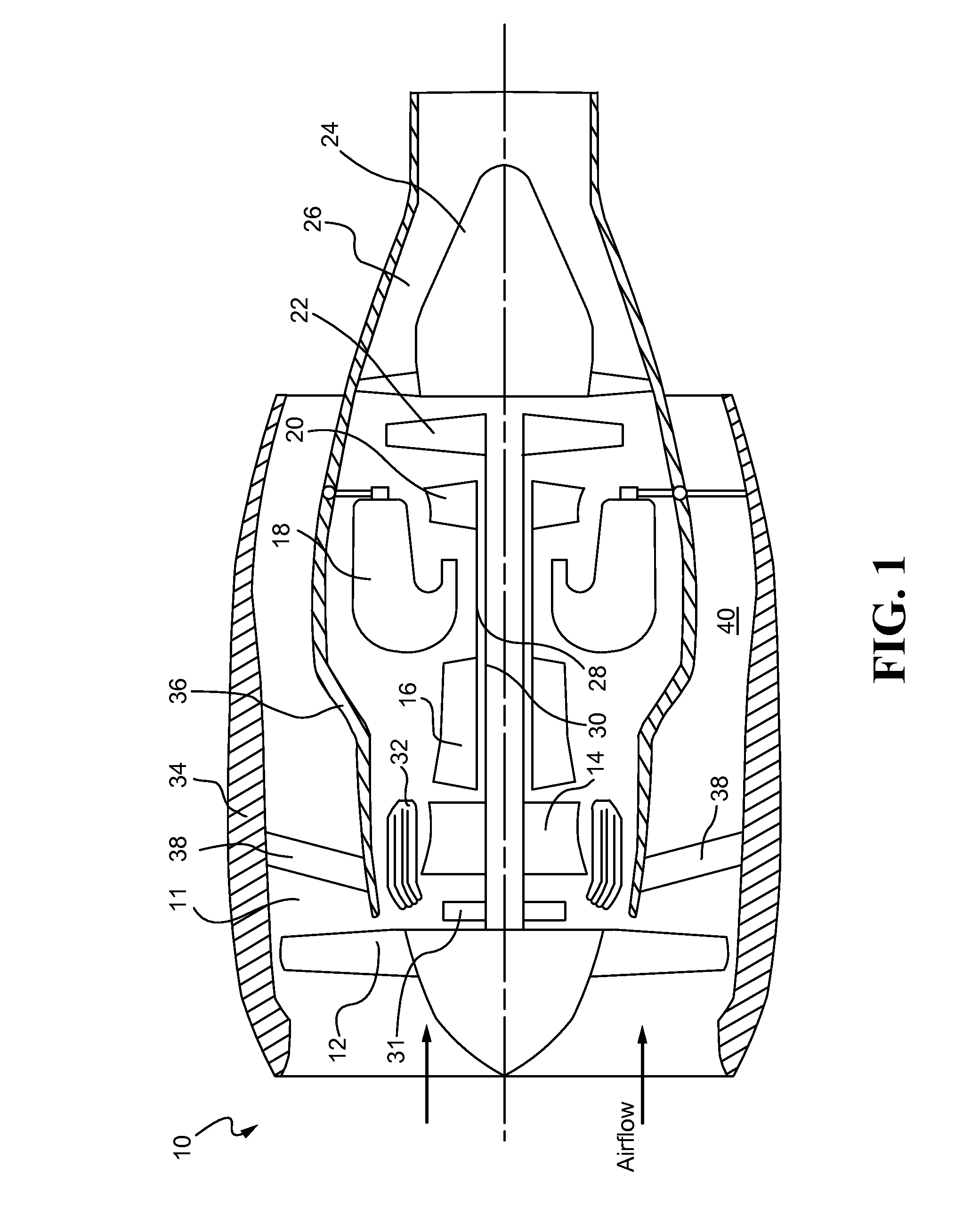

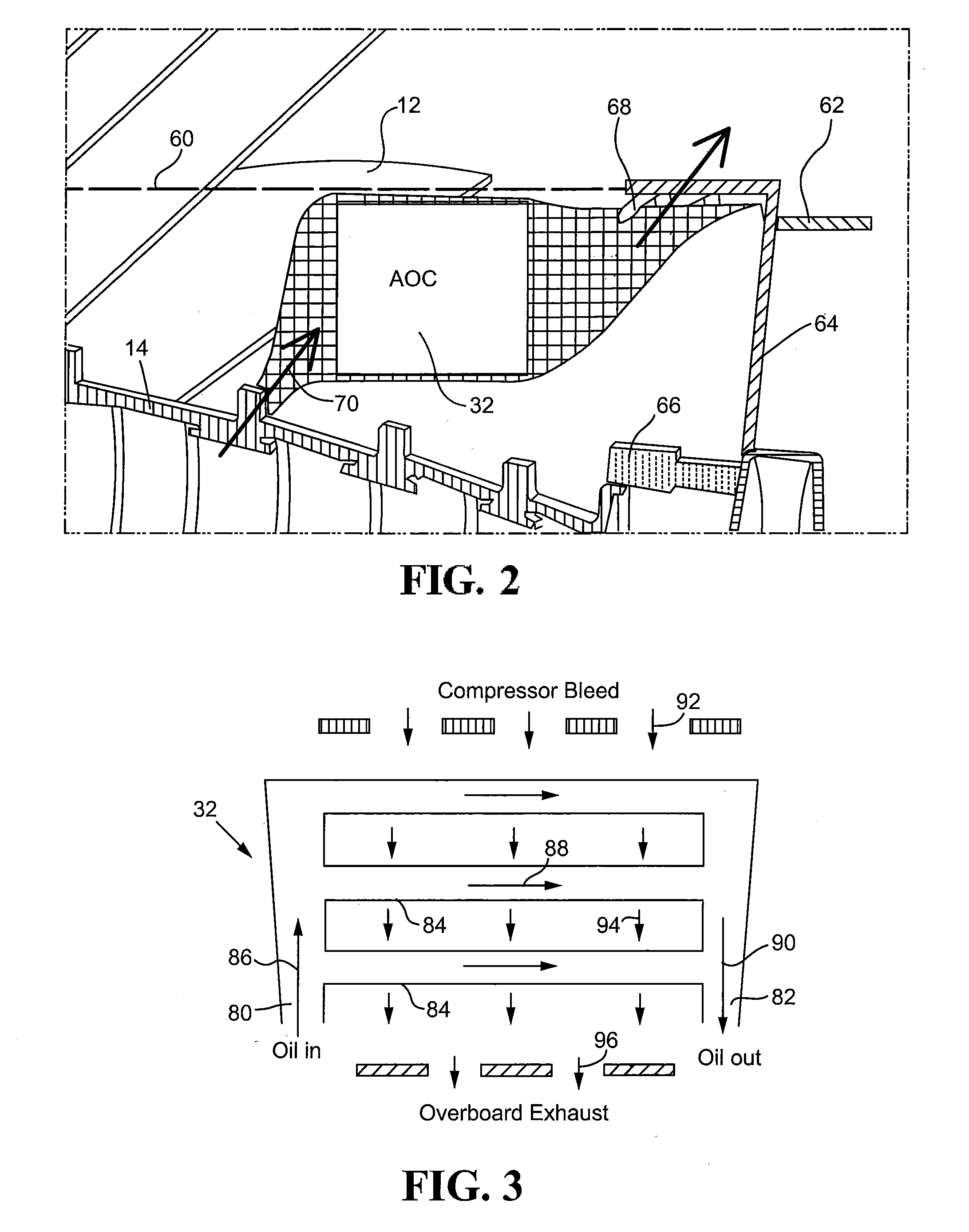

[0033]Referring now to the drawings, and with specific reference to FIG. 1, there is depicted an exemplary gas turbine 10 wherein various embodiments of the present disclosure may be utilized. In this example, the industrial gas turbine 10 may include a compressor section 11 which may comprise, sequentially from the forefront of the gas turbine engine 10, a fan 12, a low pressure compressor 14, a high pressure compressor 16, a combustor chamber 18 downstream of the compressor section 11, a high pressure turbine 20 and a low pressure turbine 22 both downstream of the combustor chamber 18, a tail cone 24, and an exhaust nozzle 26. Further, a high pressure shaft 28 may couple the high pressure compressor 16 with the high pressure turbine 20; while a low pressure shaft 30 may couple the low pressure compressor 14 with the low pressure turbine 22. Both shafts 28 and 30 may be rotatable about an axis A. The low pressure shaft 30 may drive the fan 12 through a gear train 31. There may be a lo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap