Safety logic control device for crushing and conveying of limestone

A technology of safety logic and control device, applied in the direction of program control and electrical program control in sequence/logic controllers, can solve the problems of high process power consumption, long downtime, long production downtime, etc., and reduce process power consumption. Consumption, reduce equipment failure, improve the effect of enterprise efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

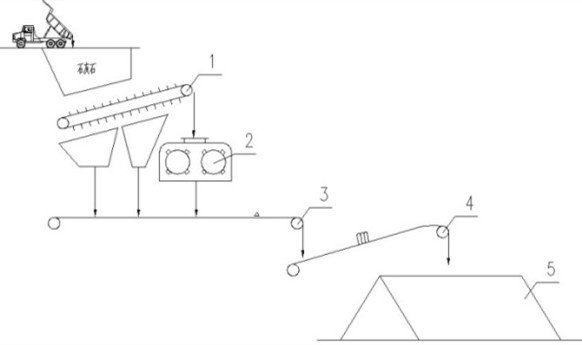

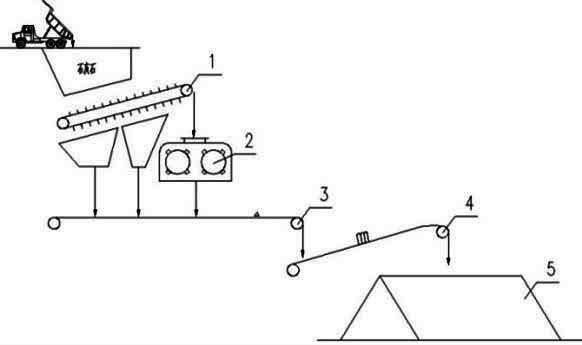

[0015] exist figure 1 Among them, a limestone crushing and transportation safety logic control device is characterized in that it includes a computer control system, apron feeder (1), crusher (2), 1# belt conveyor (3) and 2# belt conveyor machine (4), the apron feeder (1) is connected with the inlet of the crusher (2), and the outlet of the crusher (2) passes through 1# belt conveyor (3), 2# belt conveyor (4) and the limestone pre-homogeneous Chemical storage yard (5) is connected. The limestone mined from the mine is piled up in the open-air storage yard of the cement factory, and the limestone is poured into the receiving hopper by a forklift, and fed into the limestone crusher (2) through a heavy-duty apron feeder (1), and the crushed limestone It is sent to the limestone pre-homogenization yard (5) by 1# belt conveyor (3) and 2# belt conveyor (4).

[0016] When the limestone crushing system starts, the terminal equipment of the crushing system, that is, the 2# belt conveyor

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap