Conveyor belt forced positioning device for belt conveyor

A belt conveyor and positioning device technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of conveyor belt damage, support frame deformation, loss, etc., to achieve convenient installation and maintenance, and avoid damage , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

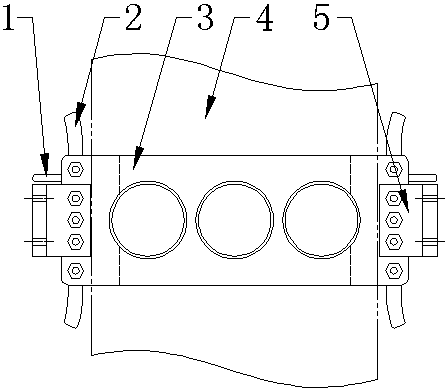

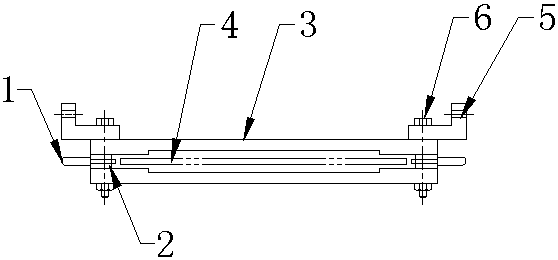

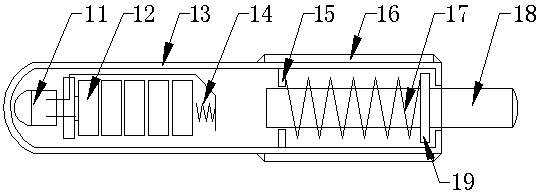

[0031] Such as Figure 1 to Figure 9 As shown, a conveyor belt forced positioning device for a belt conveyor of the present invention includes a conveyor belt guide structure and a positioning warning structure 1. The conveyor belt guide structure includes guide plates 3 arranged oppositely on the upper and lower sides of the conveyor belt 4 and on the conveyor belt. The side guide rails 2 arranged opposite to each other on the left and right sides of the conveyor belt, the two guide plates 3 and the guide rails 2 on both sides are surrounded to form a conveyor belt guide channel, and the conveyor belt 4 passes through the conveyor belt guide channel.

[0032] In this embodiment, the guide plate 3 is also fixedly connected with a positioning plate 5, the positioning plate 5 is an L-shaped plate structure formed by fixed connection

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap