Fine blanking machine work table with embedded sensor

A workbench and sensor technology, applied in the direction of metal processing, forming tools, manufacturing tools, etc., can solve the problems of personal accidental injury of operators, poor fit between mold and workbench, damage to fine blanking machine equipment, etc., to achieve safety and Improve reliability, facilitate discovery and quick repair, and work reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

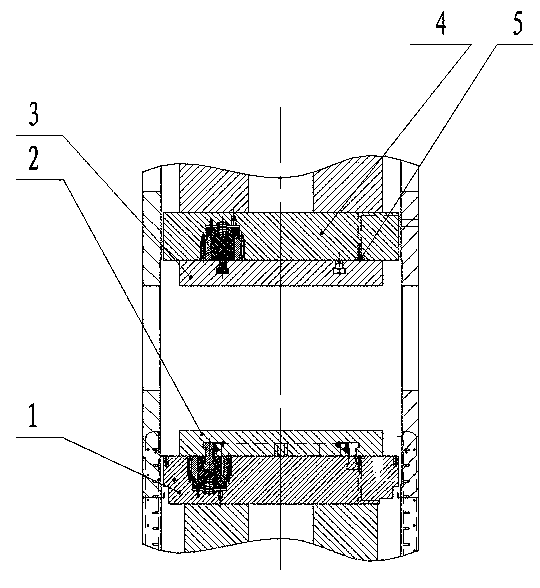

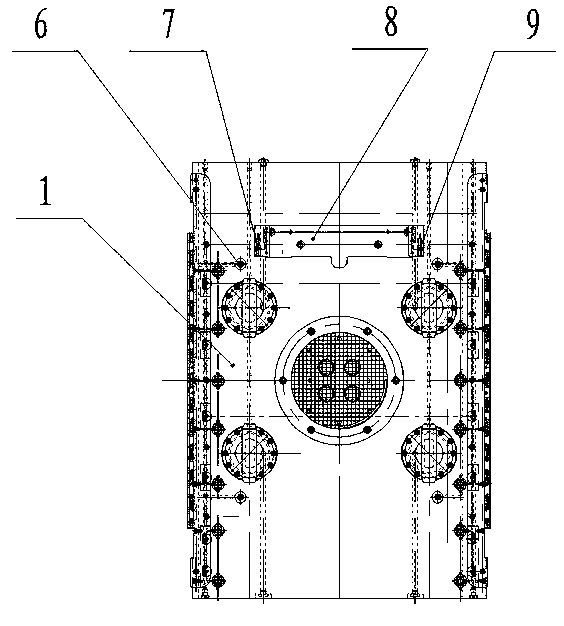

[0017] Such as figure 1 , figure 2 , Figure 4 , Image 6 As shown, the structure of the lower workbench 1 is as follows.

[0018] A plurality of sensors 26 are arranged in the lower workbench 1 of the fine blanking machine, and the lower workbench 1 is connected with the lower connecting plate 2 of the mold, and two T-shaped grooves are distributed on the left and right sides of the lower connecting plate 2 of the mold. The square groove on the rear side of the lower connecting plate 2 is in contact with the protrusion of the positioning block 8 at the rear of the lower workbench 1. The positioning block 8 is connected to the lower workbench 1. The positioning block 8 is equipped with a device that is connected to the electrical control system and can monitor the mold. Sensor three 7 and sensor four 9 are in place.

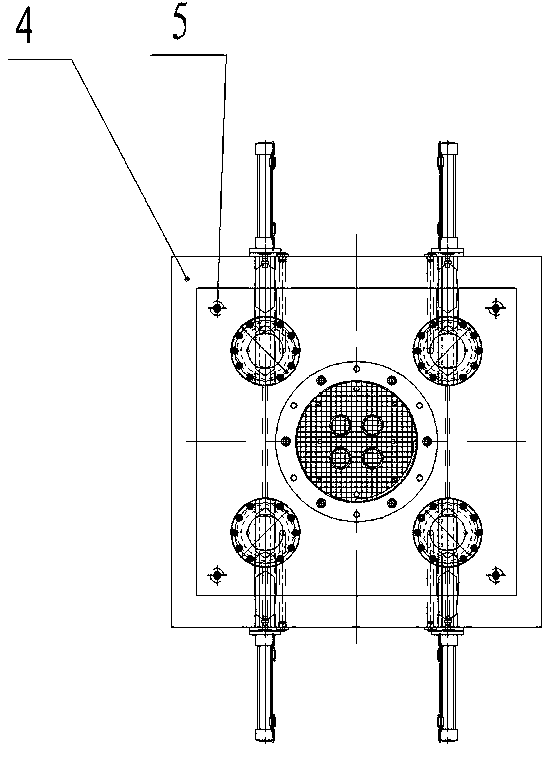

[0019] Such as figure 1 , image 3 , Figure 5 , Figure 7 Shown, the structural composition of upper workbench 4 is as follows.

[0020] A plurality of s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap