Crusher

The technology of a pulverizer and a fulcrum shaft is applied in the direction of grain processing, etc., which can solve the problems of difficult cleaning operations and time-consuming, and achieve the effect of simple structure and reduced manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

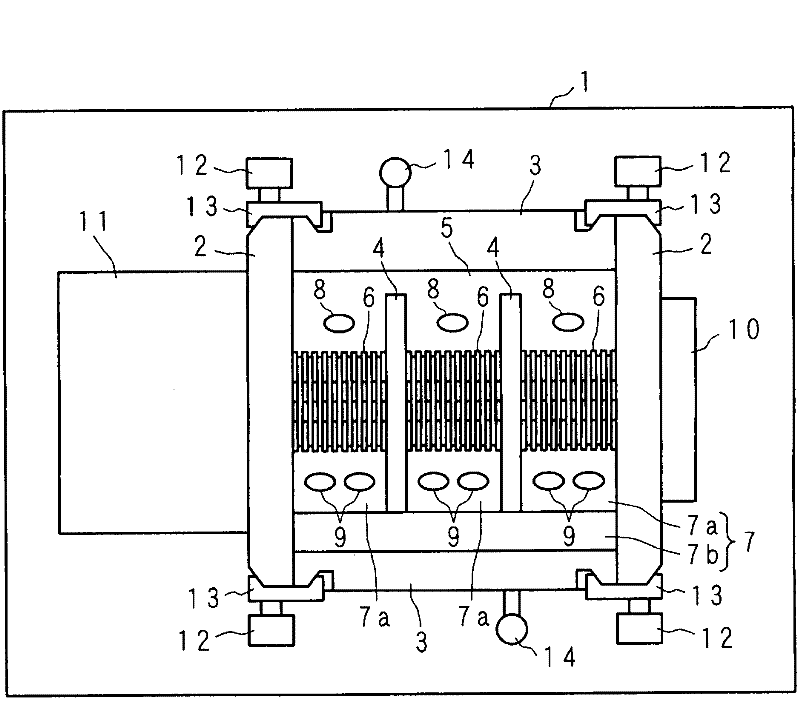

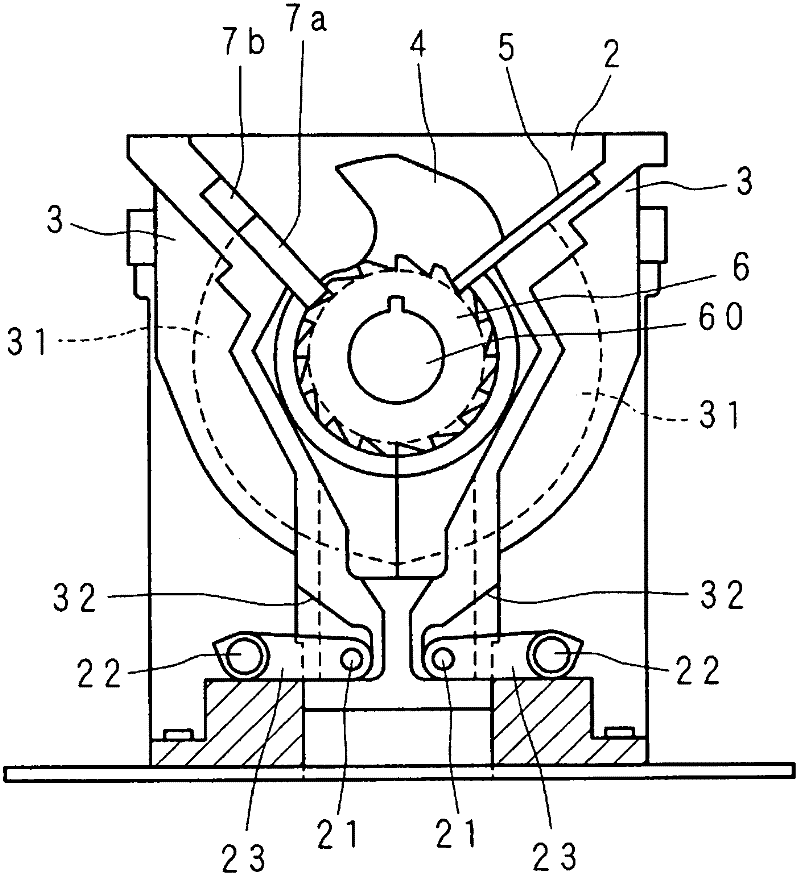

[0051] Hereinafter, this invention is demonstrated based on drawing which shows this embodiment. figure 1 It is a schematic diagram of main parts seen from the top of the pulverizer of the present invention. In the drawings, 1 is a metal support base with an open center. On the upper surface of the support platform 1, a pair of metal fixed side walls 2, 2 at an appropriate distance are oppositely arranged, on both sides of the fixed side walls 2, 2, to be clamped by the fixed side walls 2, 2 A pair of swing side walls 3, 3 made of metal are arranged in a holding manner, and the housing is composed of the fixed side walls 2, 2 and the swing side walls 3, 3. In addition, each fixed side wall 2 is fixed to the supporting table 1 with bolts.

[0052] A bearing 10 is mounted on approximately the central portion of one fixed side wall 2, and a motor 11 having a speed reducer is mounted on the other fixed side wall 2, and a rotating shaft (not shown) interlocked with the motor shaft o

Embodiment approach 2

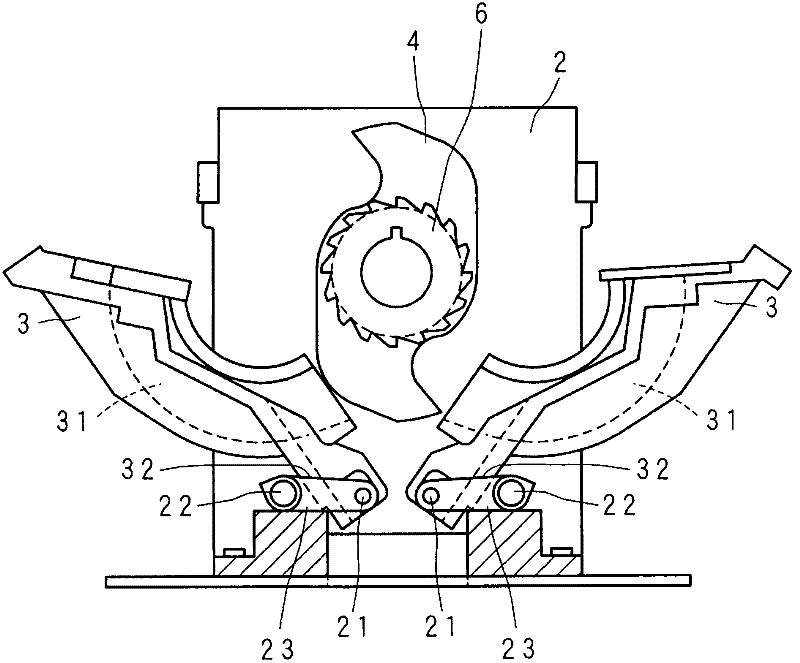

[0087] Figure 7 It is a schematic diagram of main parts seen from the front of the pulverizer of Embodiment 2. The difference from Embodiment 1 is that bolts are used instead of through shafts passing through between the fixed side walls 2 , 2 . Such as Figure 7 As shown, instead of straddling and fixing between the fixed side walls 2 and 2 , bolts 24 serving as second fulcrum axes are respectively provided on each fixed side wall 2 . That is, bolts 24 are respectively provided on the two fixed side walls 2 , 2 . The fixed side wall 2 is provided with a through hole 22c for passing a bolt 24, and a nut 22a is screwed to the bolt 24 passed through the through hole 22c and the hole 23b (another hole) of the interlocking plate 23. The bolt 24 installed in the hole 23b of the interlocking plate 23 provided between the swing side wall 3 and the fixed side wall 2 passes through the through hole 22c of the fixed side wall 2 and is screwed with the nut 22a. Accordingly, compared wi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap