Method for protecting roadway under top-cutting gob-side entry retaining of coal seam containing dirt band

A technology for retaining and retaining roadways, which is applied in tunnels, underground mining, earthwork drilling, etc., and can solve the problems of increased processing procedures and costs, waste of resources, overflow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

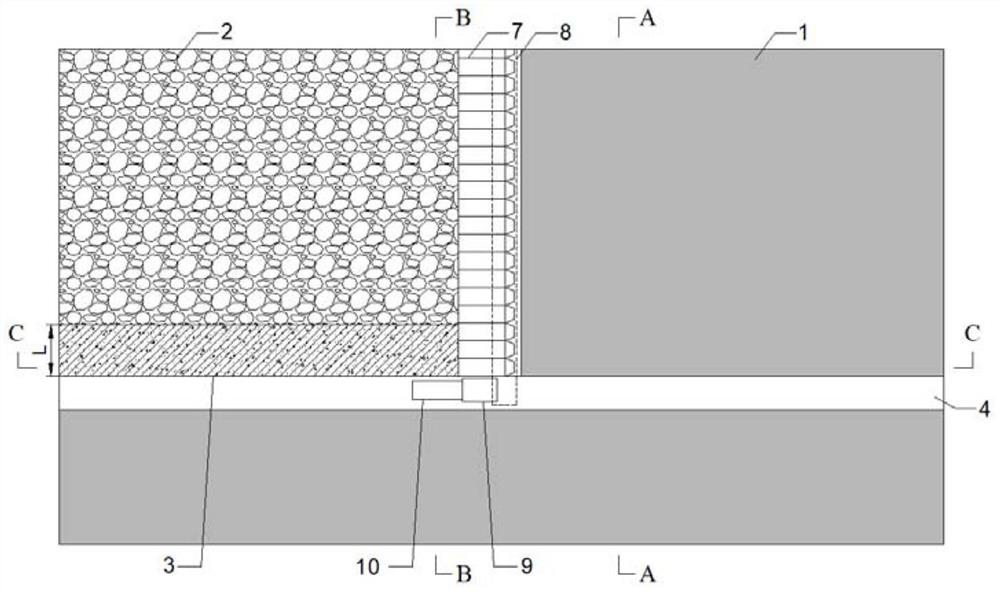

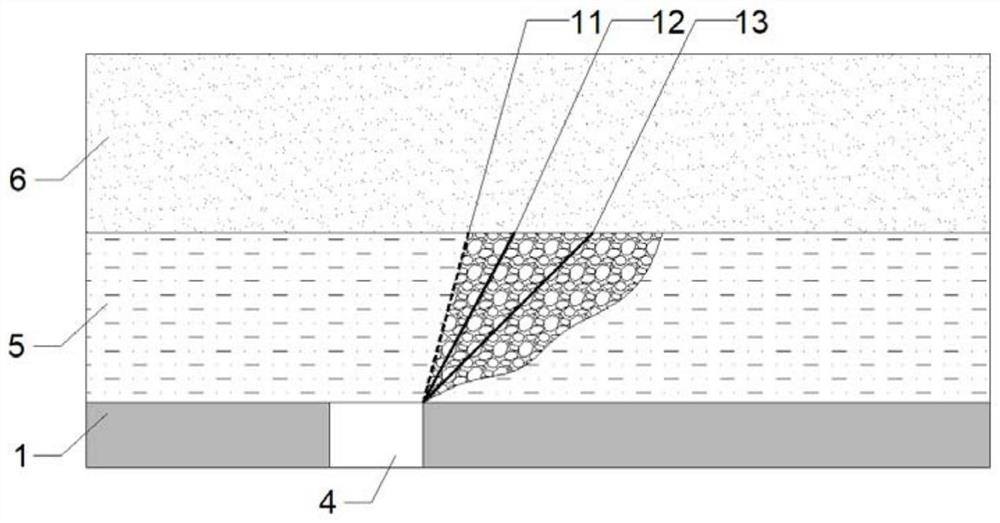

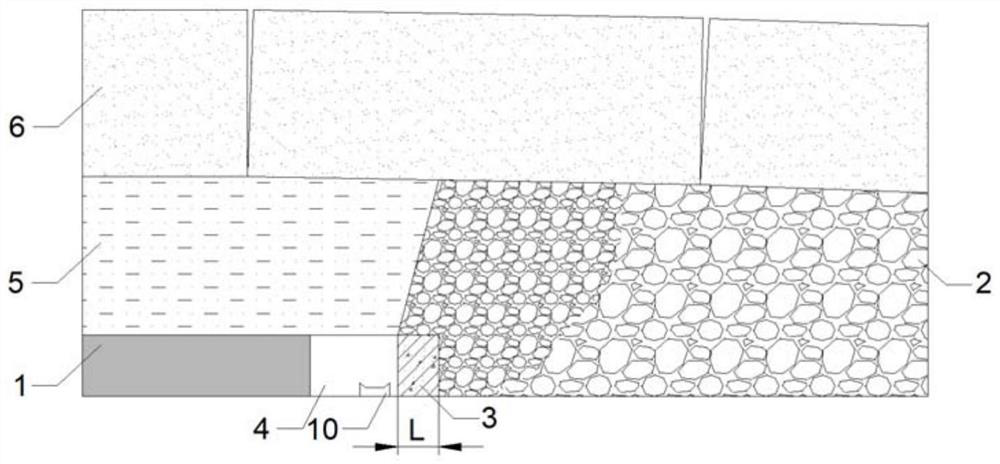

[0055] Such as Figure 1 to Figure 4 The roadway protection method that shows the roadway protection method of the present invention that contains gangue coal seam cut top and retains roadway, concrete steps are as follows:

[0056] A. First, complete the excavation of the mining roadway of the working face in the coal seam 1, and complete the layout of the working face.

[0057] B. Install the working face hydraulic support 7, scraper conveyor 8 and coal shearer and other equipment in the cutting eye of the working face.

[0058] In the above step B, pay attention that when installing the hydraulic support 7 of the working face in the cut hole, it is not installed in the transportation lane 4 of the working face, so as to reserve the installation space for the construction equipment required in the subsequent process.

[0059] C. Before the mining of the working face starts, in the transportation lane 4 of the working face in front of the cutting eye, construct the pre-splittin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap