Raw material pretreatment device for hydrogen purification

A pretreatment device and raw material technology, applied in grain processing and other directions, can solve the problem of low degree of crushing and refinement, and achieve the effect of ensuring the grinding and crushing effect and improving the crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

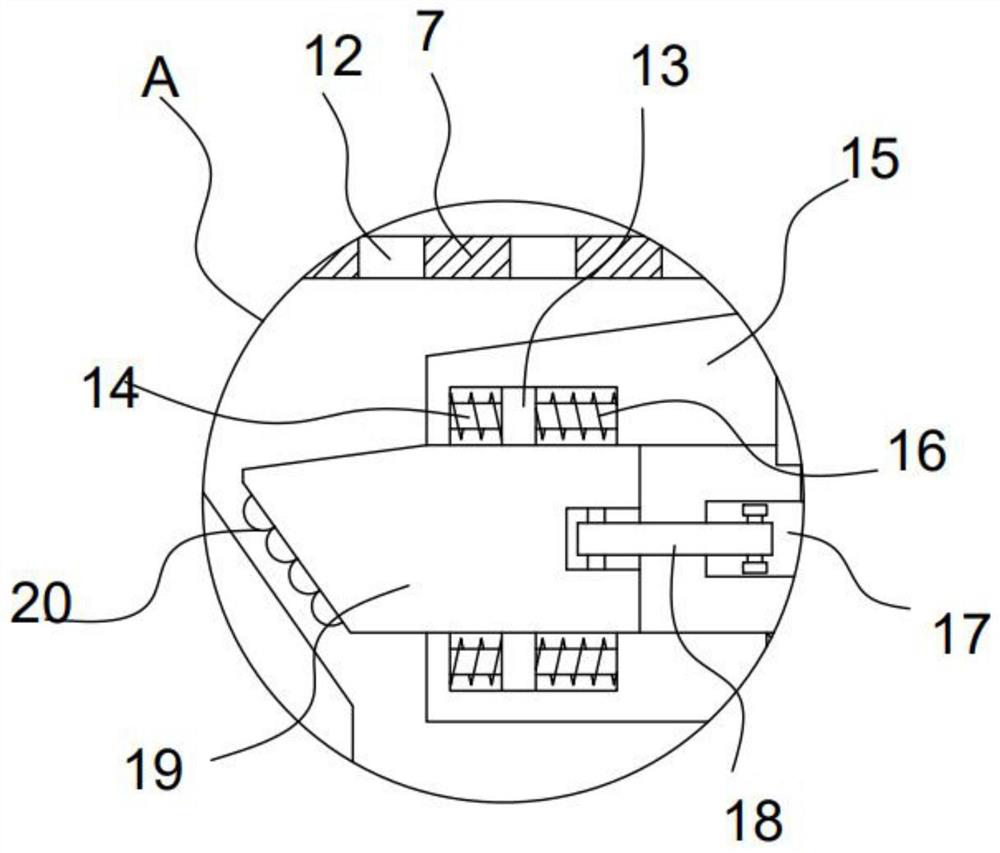

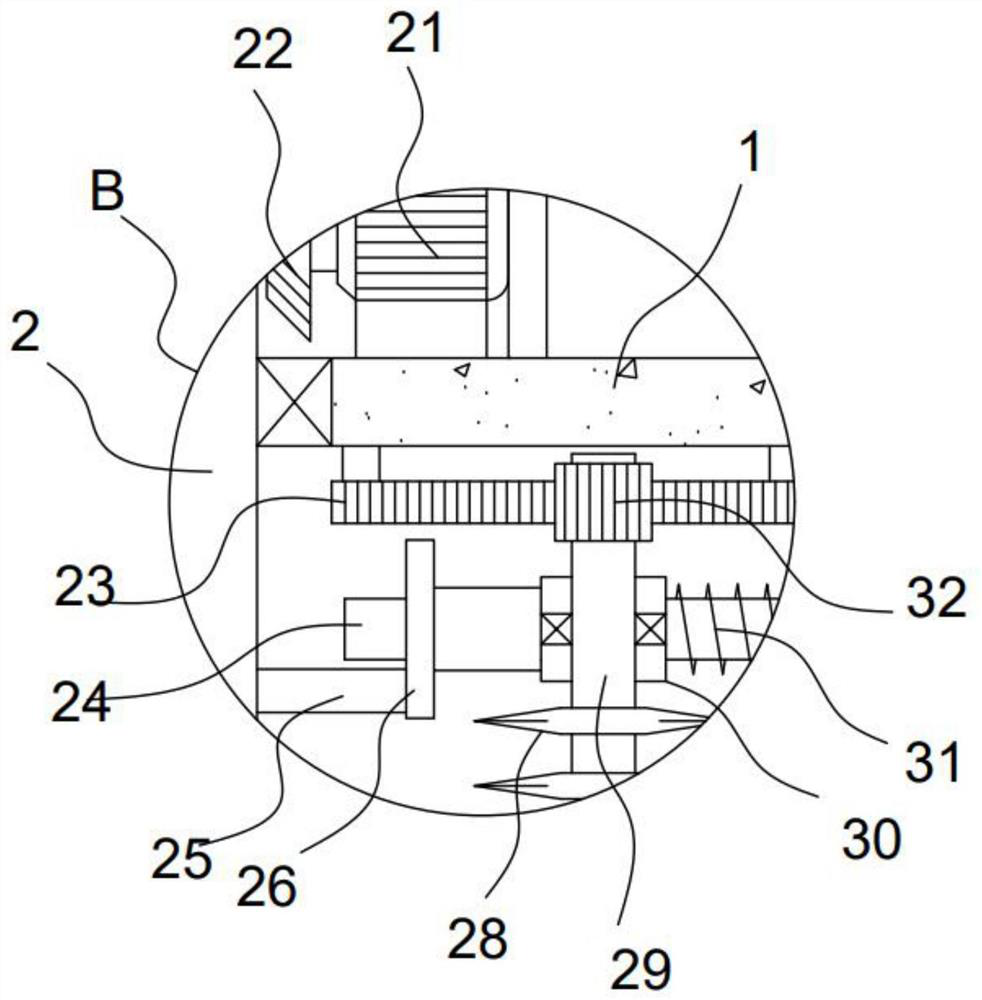

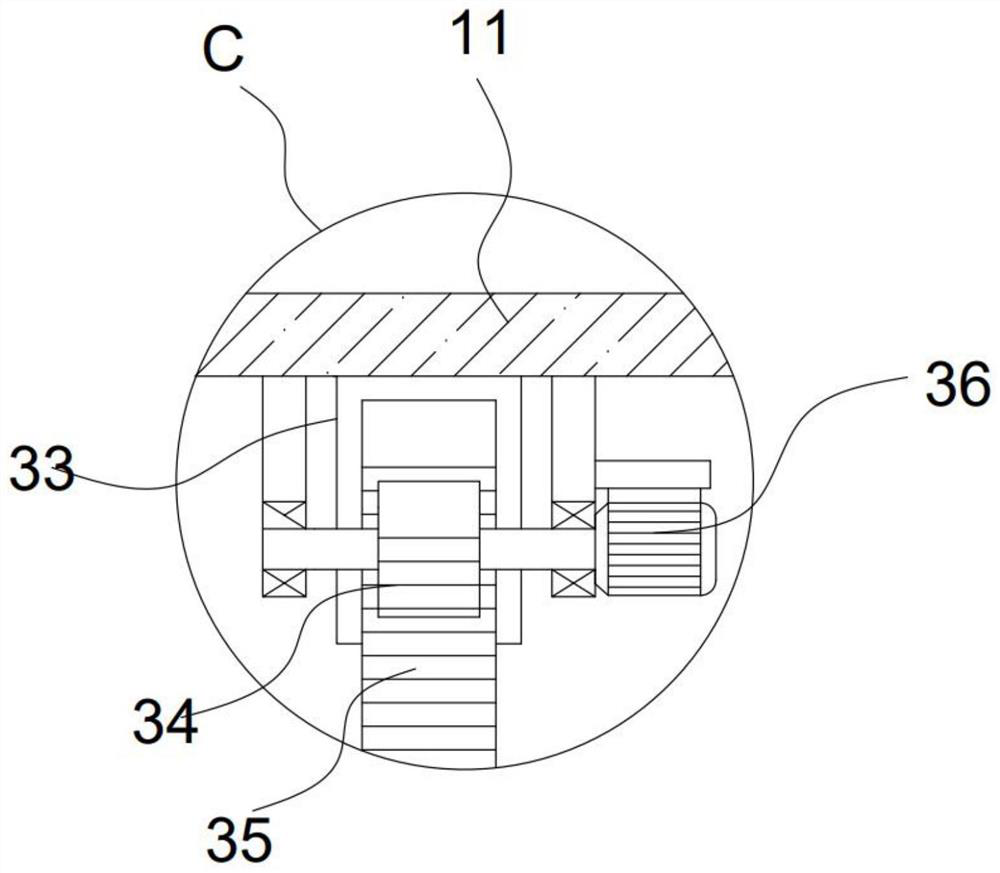

[0024] see Figure 1-5 , a raw material pretreatment device for hydrogen purification, comprising an operating frame 1, a collecting tank 11 is arranged in the operating frame 1, an annular block 8 vertically slidingly installed on the operating frame 1 is installed on the top of the collecting tank 11, and the inner wall of the annular block 8 is A wedge-shaped surface is provided, and the wedge-shaped surface extends circumferentially along the inner wall of the ring block 8. The operating frame 1 is fixed with a crushing groove 7, and the bottom of the crushing groove 7 is uniformly provided with screen holes 12, and a rotating pipe is installed in the crushing groove 7. 2. The rotating tube 2 is connected to the crushing mechanism in the crushing tank 7. The rotating tube 2 is fixed with a turntable 15 between the crushing tank 7 and the ring block 8. The side wall of the turntable 15 slides on the ring block. The wedge-shaped surface of 8 is opposite to the telescopic grindi

Embodiment 2

[0030] On the basis of Embodiment 1, in addition, the refined anthracite falls vertically through the sieve hole 12, and at the same time, the rotating tube 2 drives the rotating disk 15 fixed coaxially with it to rotate, and the telescopic grinding block 19 on the rotating disk 15 The grinding bump 20 then rotates and further grinds and refines the anthracite between it and the ring block 8 , which greatly improves the degree of refinement of the anthracite.

[0031] In addition, in order to adjust according to the degree of crushing and refinement of anthracite, the device is also provided with an adjustment mechanism, which includes an adjustment shaft 27 vertically penetrating through the rotating tube 2. The turntable 15 is a hollow structure, and the adjustment shaft 27 extends to the inside of the turntable 15. A pull rod 18 is eccentrically hinged on the turntable 15, and the end of the pull rod 18 away from the adjusting wheel 17 is hinged to a telescopic grinding block 1

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap