Metal detecting and sorting-out system

A metal detection and metal technology, applied in sorting, magnetic separation, solid separation, etc., can solve problems such as inability to complete sorting steps, structure and protection system risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

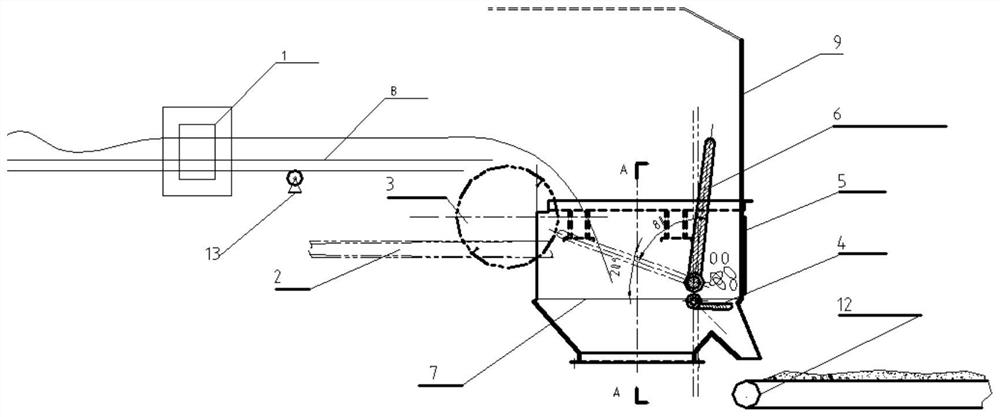

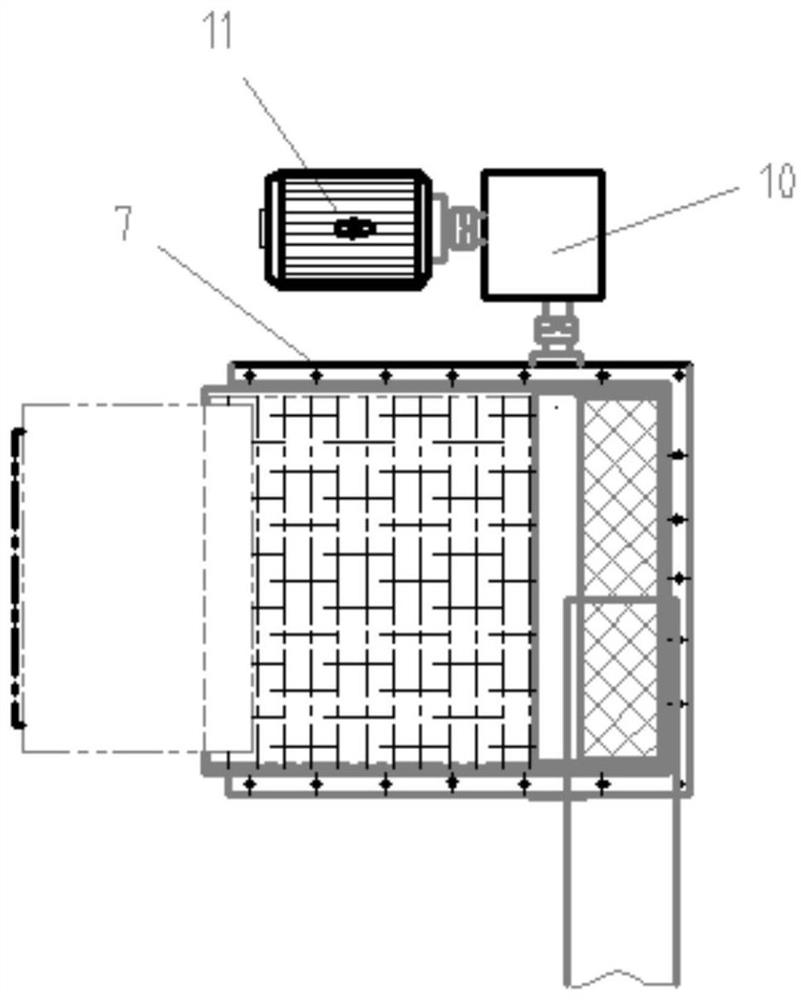

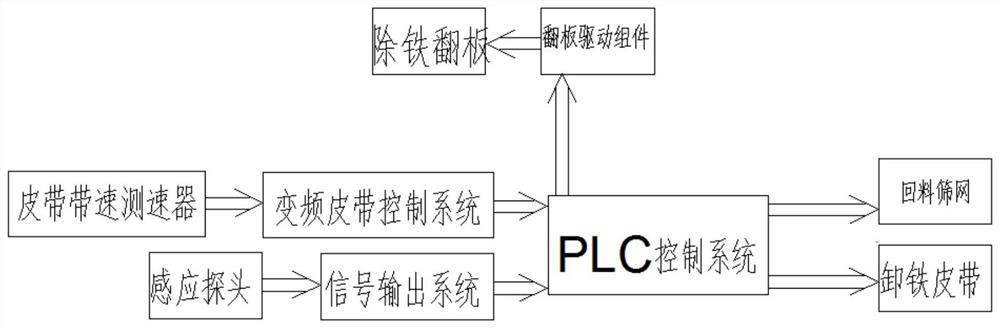

[0037] Such as Figure 1-Figure 3 As shown, a metal detection and sorting system provided in this embodiment includes equipment for the metal detection and sorting system and a metal detection and sorting system, wherein the equipment for the metal detection and sorting system includes a cavity 7 and is installed in The flap drive assembly on one side of the cavity 7, the top side of the cavity 7 is provided with a conveying assembly that sends minerals into the cavity 7, the outside of the conveying assembly is provided with an induction probe 1, and the inner side of the cavity 7 is installed There is a return screen 4 and an iron removal flap 6 is installed through

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap