Movable jaw plate of jaw crusher

A jaw crushing and jaw plate technology, applied in grain processing and other directions, can solve the problems of no positioning structure at the joint, parking maintenance, moving jaw plate falling, etc., to reduce the frequency of parking maintenance, reduce the failure maintenance rate, prevent Effects of equipment accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments provided by the present invention are described in further detail in conjunction with the accompanying drawings:

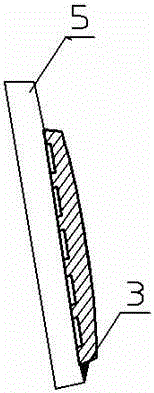

[0017] A mobile jaw plate for jaw crushing, the movable jaw plate is installed on the movable jaw assembly, positioning blocks 1 are respectively arranged at both ends of the movable jaw plate, and the positioning blocks 1 are respectively clamped on the movable jaw assembly 5, in the slots on both sides, several hanging holes 2 are provided on the back of the movable jaw plate, and the hanging holes 2 are matched with the hanging hooks on the movable jaw assembly 5.

[0018] Such as Figure 4-6 As shown, wherein, there are two positioning blocks 1, which are respectively located at both ends of the movable jaw plate, and the positioning blocks 1 are in a rectangular structure.

[0019] There are four suspension holes 2, two suspension holes 2 are located at one end of the movable jaw plate, and the other two suspension holes 2 are located at the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap