Hammer crusher for ore mining

A hammer crusher and crushing device technology, applied in the field of ore processing, can solve the problems of inability to concentrate ore stacking, inconvenience for users, and reduce the practicability of the crusher, so as to improve practicability, facilitate movement, and increase practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

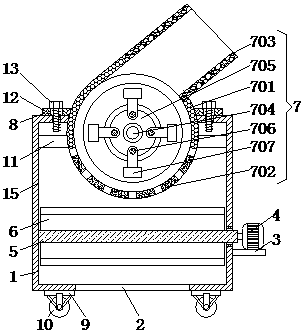

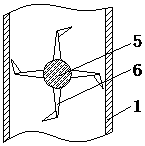

[0016] See Figure 1-2 , A hammer crusher for ore mining, including a box body 1, both sides of the bottom of the box body 1 are fixedly connected with a bracket 9, the bottom of the bracket 9 is movably connected with a roller 10 through a rotating shaft, through the setting of the bracket 9 and the roller 10 , It is convenient to move the crusher, which increases the practicability of the crusher. The tops of both sides of the inner cavit

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap