Method and device for pulverizing deep-sea cobalt crust

A technology of crust breaking and deep sea, which is applied in grain processing and other directions, can solve the problems affecting the safe walking of cobalt crust concentrators and limit the running speed of the concentrator, so as to improve the walking speed and work efficiency, and achieve high switching frequency. , the effect of reducing the mechanical cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

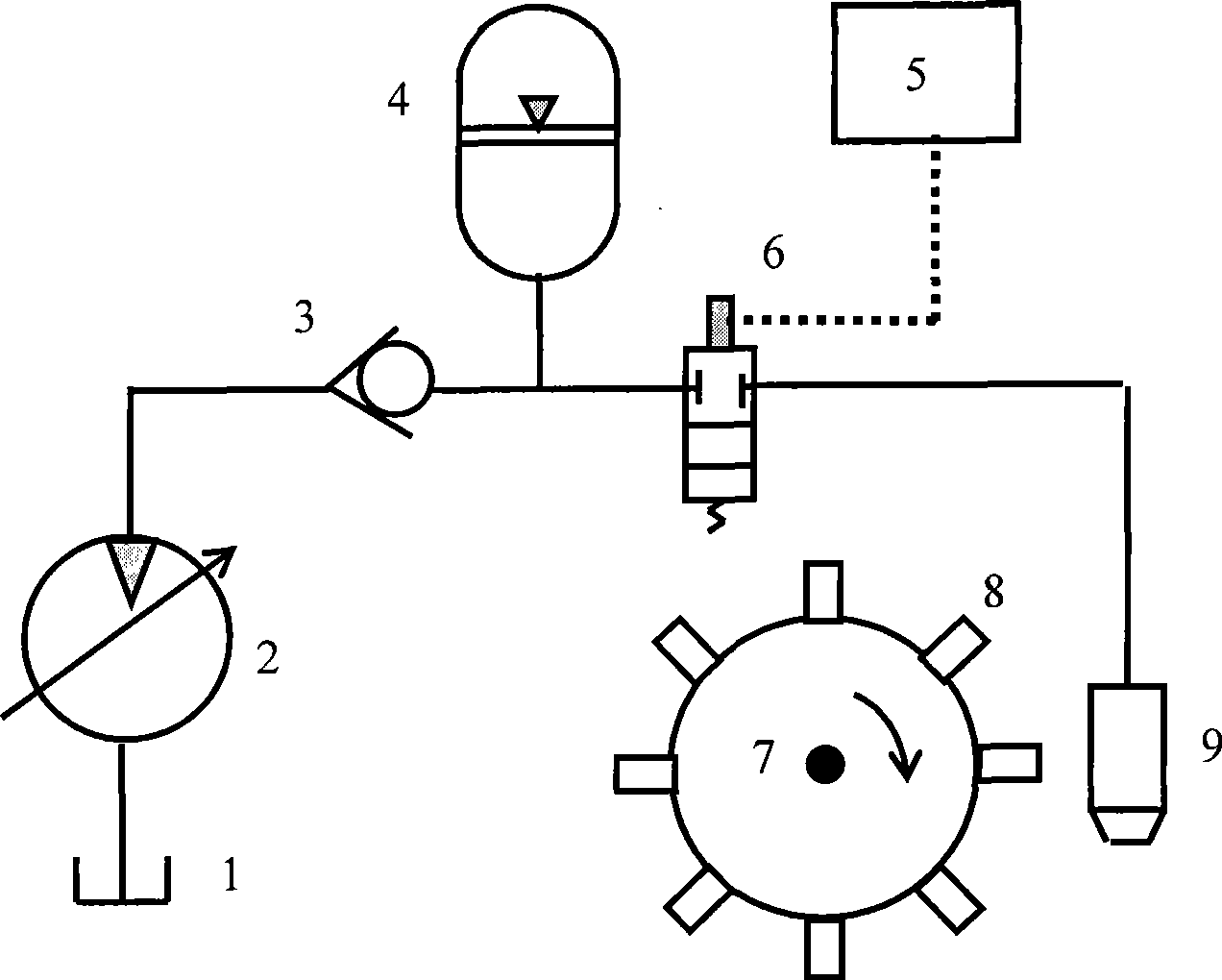

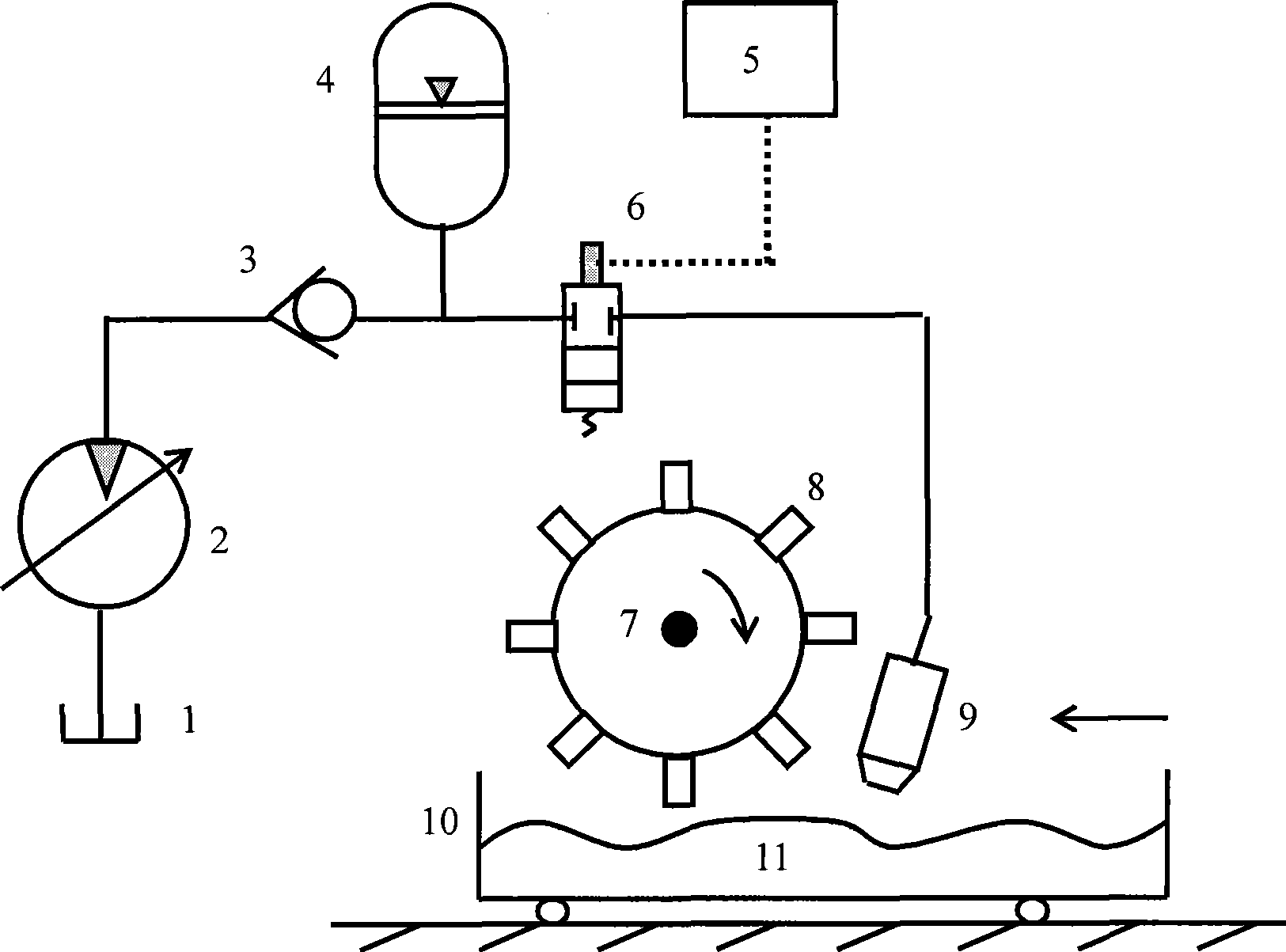

[0020] figure 1 It is a schematic diagram of a cobalt crust mechanical tooth and water jet combined crushing device, including a water tank 1, a high-pressure pump 2, a one-way valve 3 (that is, the first valve in the content of the invention), an accumulator 4, a controller 5, and two-position two-way Solenoid valve 6 (i.e. the second valve in the Summary of the Invention), drum 7, mechanical teeth 8 and nozzle 9. The inlet of the high-pressure pump 2 is connected to the water tank 1, the inlet of the one-way valve 3 is connected to the outlet of the high-pressure pump 2, the outlet of the one-way valve 3 is connected to the inlet of the two-position two-way solenoid valve 6, and the accumulator 4 is connected to the one-way Between the valve 3 and the two-position two-way solenoid valve 6 , the outlet of the two-position two-way solenoid valve 6 is connected to the nozzle 9 . Mechanical teeth 8 are mounted on the outer surface of the drum 7 . The nozzle 9 is located directly

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap