Cement mortar

A cement mortar and iron ore technology, applied in the field of cement mortar, can solve the problems of poor shielding effectiveness, complex shielding structure, and low strength of shielding materials, and achieve the effects of convenient application, high shielding effect, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

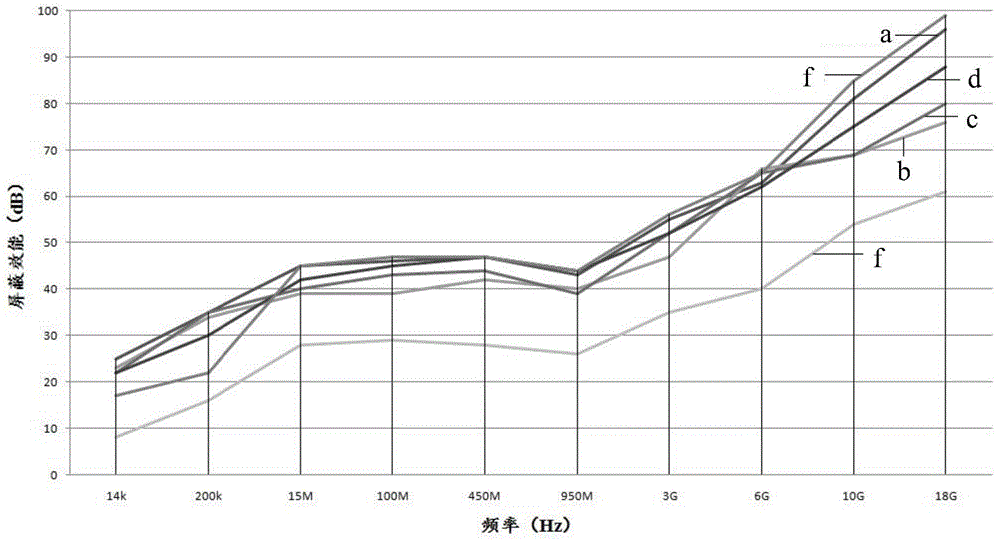

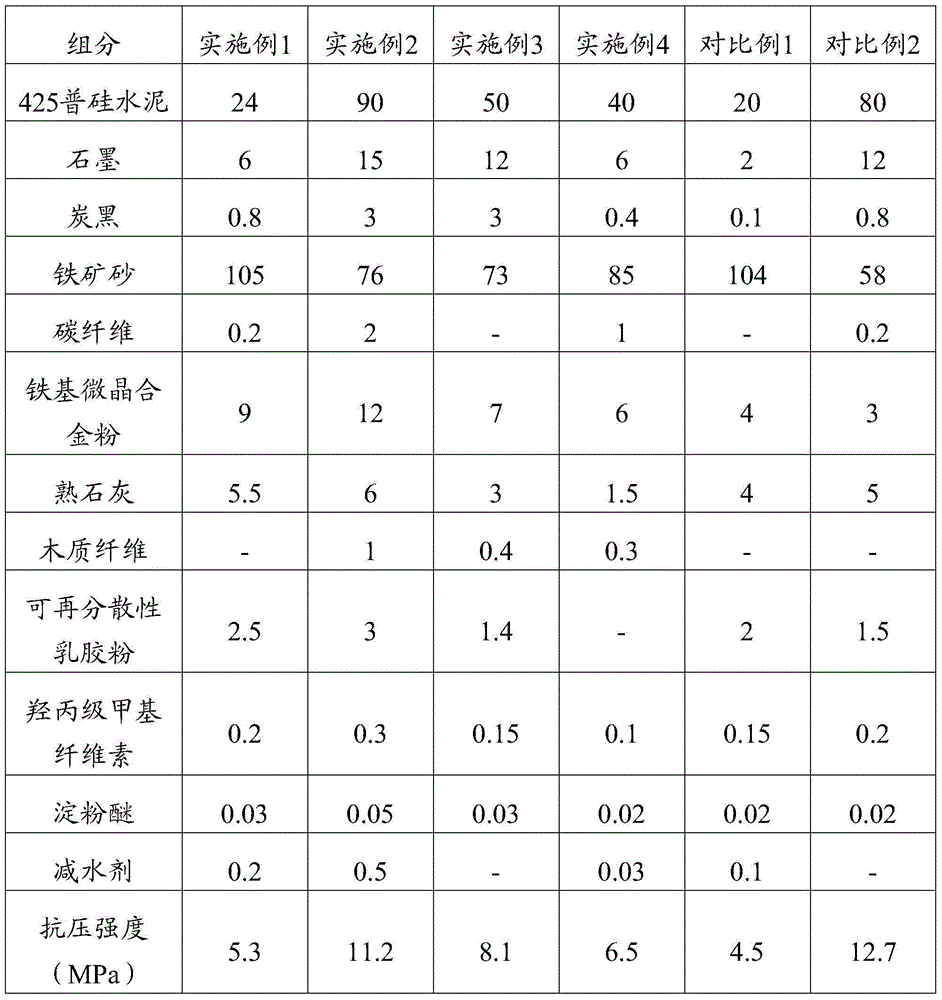

[0036] The electromagnetic wave shielding material of the cement mortar in Example 1 is composed of graphite, carbon black, iron ore, carbon fiber and iron-based microcrystalline alloy powder. The organic additives of the cement mortar in Example 1 consisted of redispersible latex powder, hydroxypropyl methylcellulose, starch ether and water reducing agent. The cement mortar of Example 1 does not contain wood fibers. The concrete composition of the cement mortar of embodiment 1 is as shown in table 1, and the compressive strength of cement mortar is as shown in table 1, and the shielding effectiveness of cement mortar is as shown in table 1. figure 1 shown.

Embodiment 2

[0038] The electromagnetic wave shielding material of the cement mortar in Example 2 is composed of graphite, carbon black, iron ore, carbon fiber and iron-based microcrystalline alloy powder. The organic additives of the cement mortar in Example 2 consisted of redispersible latex powder, hydroxypropyl methylcellulose, starch ether and water reducing agent. The concrete composition of the cement mortar of embodiment 2 is as shown in table 1, and the compressive strength of cement mortar is as shown in table 1, and the shielding effectiveness of cement mortar is as shown in table 1. figure 1 shown.

Embodiment 3

[0040] The electromagnetic wave shielding material of the cement mortar in Example 3 is composed of graphite, carbon black, iron ore and iron-based microcrystalline alloy powder. The organic additives of the cement mortar in Example 3 consisted of redispersible latex powder, hydroxypropylmethylcellulose and starch ether. The concrete composition of the cement mortar of embodiment 3 is as shown in table 1, and the compressive strength of cement mortar is as shown in table 1, and the shielding efficiency of cement mortar is as shown in table 1. figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap