Cement manufacturing apparatus and method

a manufacturing apparatus and cement technology, applied in the direction of solid waste management, climate sustainability, solid separation, etc., can solve the problems of increasing the quantity of unburned carbon contained, the difficulty of fly ash waste treatment, and the difficulty of perfectly removing unburned carbon contained in fly ash, etc., to achieve the effect of increasing the quantity of fly ash used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

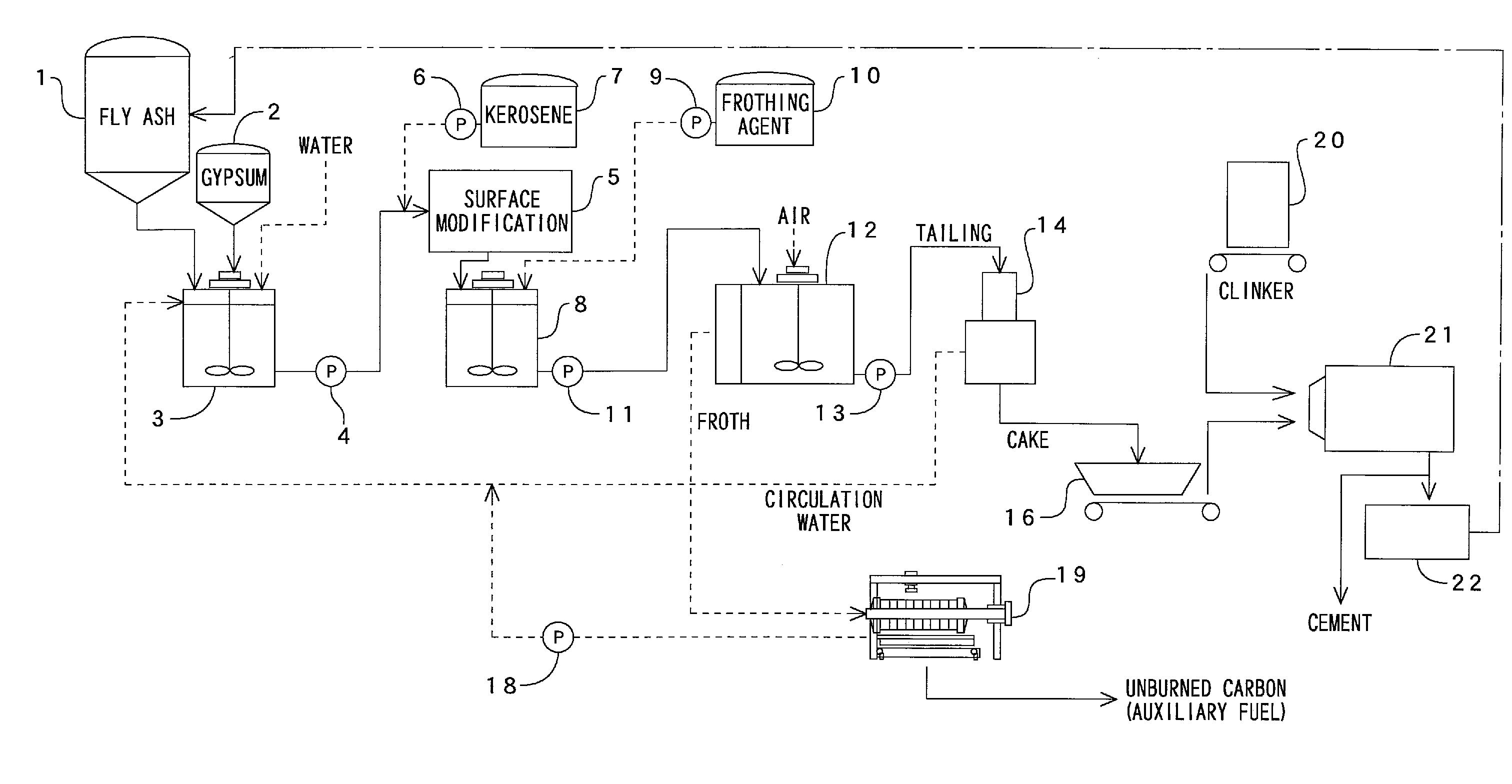

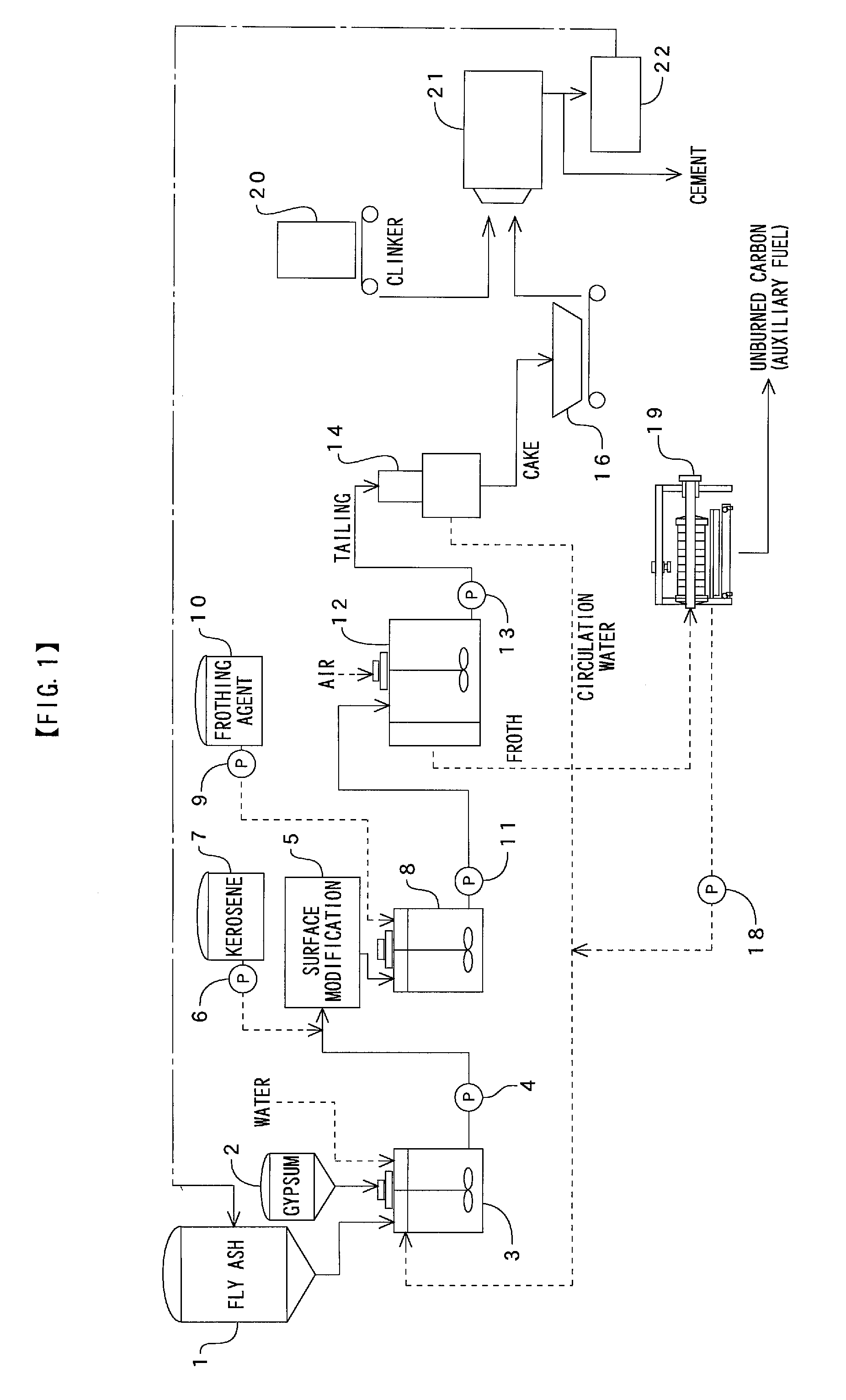

[0024]FIG. 1 shows an example of a system composition to which a cement manufacturing apparatus and method according to the present invention are applied, and this system roughly comprises a fly ash tank 1, a gypsum tank 2, a slurry tank 3 for generating slurry by adding water to fly ash and gypsum, a surface modifier 5 for adding sharing force to slurry after adding collector to the slurry to modify the surface of unburned carbon, an adjustment tank 8 for generating air bubbles by adding frothing agent to slurry, a flotation machine 12 for separating unburned carbon from fly ash and gypsum by causing the unburned carbon to adhere to the air bubbles and making them float, a solid / liquid separator 14 for solid / liquid separating tailing from the flotation machine 12, a filter press 19 for obtaining unburned carbon by solid / liquid separating froth from the flotation machine 12, a clinker silo 20 for storing clinker, a cement mill 21 for generating cement by grinding clinker, fly ash

PUM

| Property | Measurement | Unit |

|---|---|---|

| Content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap