Method of using sludge neutralized by steel pickling wastewater to prepare yellow soil parent material

A yellow loam parent material and iron and steel pickling technology, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem of low iron content in sludge, no use value, and the economic burden of processing costs. , soil and global environmental pollution, etc., to achieve the effect of wide product use, convenient operation and large amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

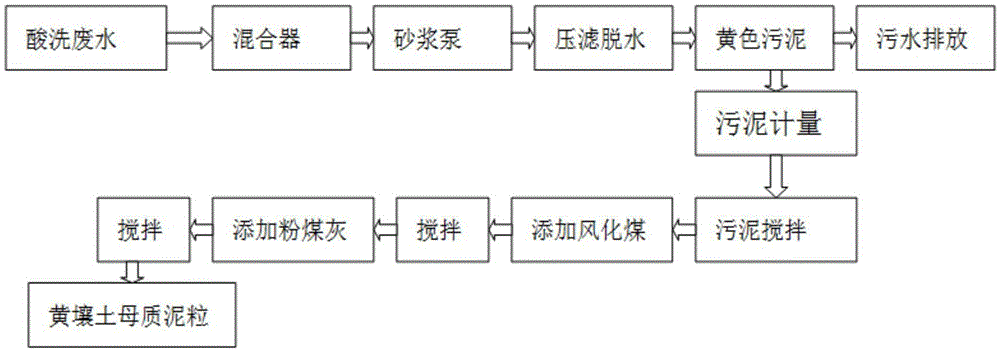

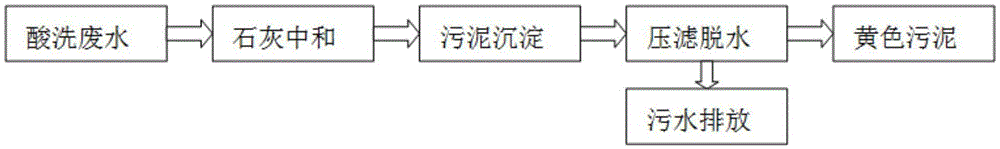

[0030] A method for preparing yellow loam parent material from sludge after neutralization of iron and steel pickling wastewater. The preparation process is as follows: iron and steel pickling wastewater is pumped into a pipeline mixer with an acid-resistant pump, and white mortar is added to adjust the mortar for mixing. After mixing, press filter, press Obtain the sludge filter cake after filtration, add weathered coal containing humic acid to the sludge filter cake under stirring, the mass ratio of sludge to weathered coal is 5:1-2, add fly ash after stirring evenly, sludge and weathered coal The mass ratio of fly ash is 10:1-3, and it is made into mud pellets to obtain artificial iron oxide-based yellow loam parent material.

[0031] The specific operation implementation process of this embodiment:

[0032] Put 100 cubic meters of pickling waste water into the pipeline mixer with an acid-resistant pump, add lime slurry to neutralize the acid and alkali, adjust the amount of l

Embodiment 2

[0035] A method for preparing yellow loam parent material from neutralized sludge from iron and steel pickling wastewater, the preparation process of which is the same as in Example 1. Among them, 100 cubic meters of pickling waste water is driven into the pipeline mixer with an acid-resistant pump, and white mortar is added to neutralize the acid and alkali to adjust the mortar intake to make the pH value of the mixer outlet to = 6.5. Use a mortar pump to drive into a box-type filter press to maintain a pressure of 0.4-0.6 MPa for pressure filtration, and the water content of the sludge filter cake (dark green) after the pressure filtration is 45-65%. Obtain 20 cubic meters of ferrous hydroxide sludge that has not been oxidized. Use a forklift to shovel the sludge into 1.5 cubic meters and weigh it according to the weight ratio of mud to weathered coal 10:3. Add it to the cement mixer and stir to make the sludge and air-dried coal fully mixed, and then according to the ratio of

Embodiment 3

[0037] The use of sludge after neutralization of iron and steel pickling wastewater to prepare yellow loam parent material, the yellow loam parent material is used as a heavy metal adsorbent for removing copper or zinc in copper or zinc-containing heavy metal wastewater. When removing copper or zinc in heavy metal wastewater containing copper or zinc, add yellow loam parent material mud particles to heavy metal wastewater containing copper and zinc, adjust PH = 6.5-7 with lime, and settle for 3-6 hours to absorb heavy metals. Sewage environmental protection discharge.

[0038]Use of sludge after neutralization of iron and steel pickling wastewater to prepare yellow loam parent material. Add 200 kg of the artificial yellow loam mud mass particles prepared in Example 1 into 30 cubic meters of copper-zinc-containing waste water from the musical instrument workshop, and pneumatically stir it with lime to adjust the pH to 6.5-7. After 4 hours of static precipitation and adsorption of

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap