Cement composition and concrete composition using same

A technology of concrete composition and cement composition, which is applied in the field of engineering materials, can solve the problems of complex construction technology, early strength of concrete, large mixing amount, etc., and achieve the effect of simple formula, high compressive strength, and easy raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The composition ratio of the cement composition is 26% of ground Portland cement clinker, 68% of ground slag powder, 5% of silica fume, 0.9% of calcium sulfate, and 0.1% of Fe powder. The weight of the Portland cement is added as The benchmark 3.6% mixture, it is made by RO(AO) n H and HO (AO) m R represents the composition of the substance, where R is C 3 Alkenyl, O is oxygen atom, A is C 4 Alkylene, n is 3, m is 2, and the weight ratio of the former to the latter is 2:1.

[0019] The chemical composition of ground Portland cement clinker is: SiO 2 20%, Fe 2 O 3 Is 4.5%, Al 2 O 3 It is 3.2%, CaO is 63.6%, and MgO is 8.7%.

[0020] 2 parts by weight of the above cement composition, 3 parts by weight of natural construction sand, 1.5 parts by weight of additives, which consist of 55% of hydroxymethyl cellulose and 45% of sodium lauryl sulfate.

Embodiment 2

[0022] The composition ratio of the cement composition is 31.7% of ground Portland cement clinker, 61% of ground slag powder, 6% of silica fume, 1% of calcium sulfate, and 03% of Fe powder. The weight of the Portland cement is added as Baseline 3.9% mixture, it is made by RO(AO) n H and HO (AO) m R represents the composition of the substance, where R is C 5 Alkenyl, O is oxygen atom, A is C 6 Alkylene, n is 5, m is 4, and the weight ratio of the former to the latter is 3:1.

[0023] The chemical composition of ground Portland cement clinker is: SiO 2 20.2%, Fe 2 O 3 4.6%, Al 2 O 3 It is 3.3%, CaO is 63.6%, and MgO is 83%.

[0024] 2.5 parts by weight of the above-mentioned cement composition, 33 parts by weight of natural building sand, and 1.7 parts by weight of additives, which consist of 65% of hydroxypropyl methylcellulose and 35% of sodium dodecyl sulfonate.

Embodiment 3

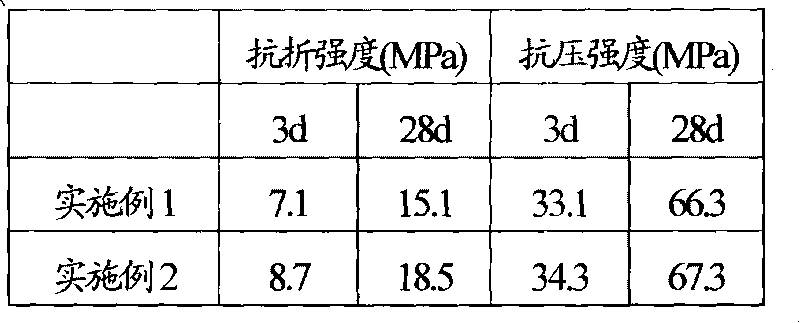

[0026] The following are the results of the physical and chemical properties of the cement products of Examples 1 and 2:

[0027]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap