Interfacial agent for binding vitrified tiles and construction method thereof

A vitrified brick and interface agent technology, which is applied in the field of building bonding materials and its construction, can solve problems such as ineffective effects, and achieve the effects of increasing surface area, improving adhesive force, and increasing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

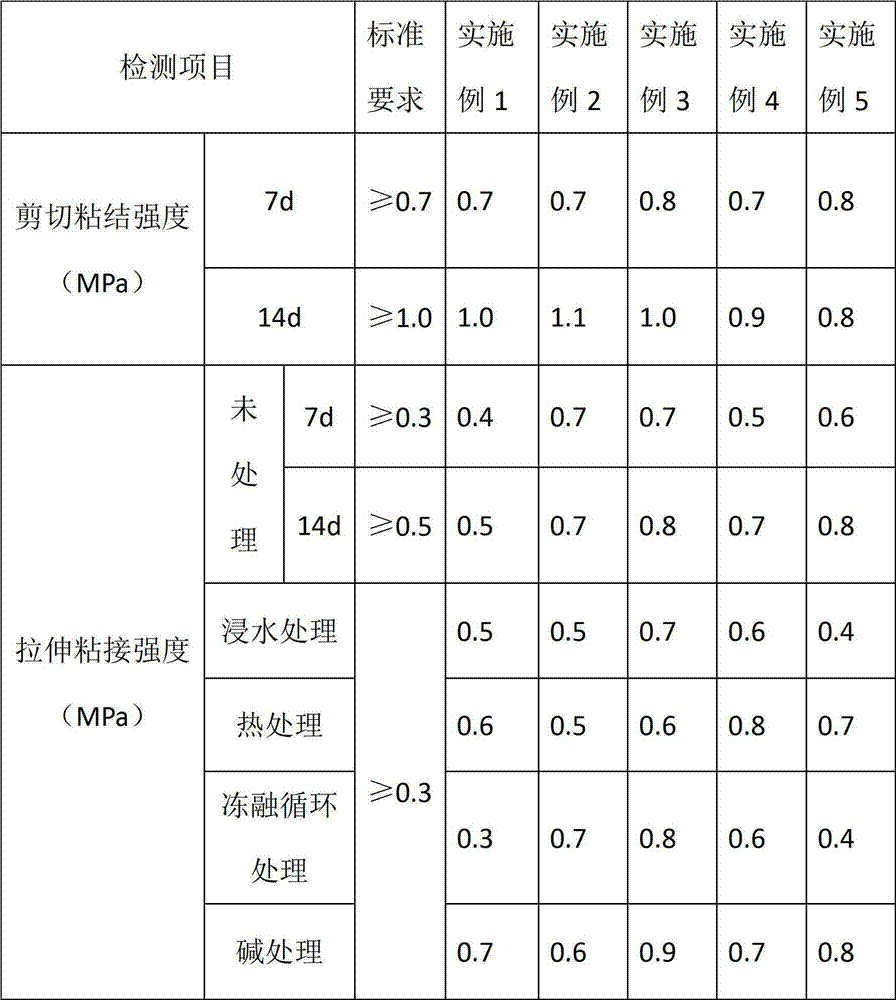

[0016] Under normal temperature and pressure, according to the components specified in Example 1 in Table 1 below, the expanded perlite, cationic emulsion, and wood fiber were mixed, and stirred evenly with a stirring gun to obtain an interface agent for vitrified tiles.

[0017] The national standard JC / T907-2002 is used to test the performance of the interface agent for vitrified tiles, and the test results are listed in Table 2.

[0018] During construction, use a roller to evenly brush the interface agent on the adhesive surface of the vitrified brick, let it air for 10 minutes, and then use adhesive mortar to paste it on the wall.

Embodiment 2

[0020] Repeat the method of Example 1 according to the content of each component specified in Example 2 in Table 1 below, but use a brush to evenly brush the interface agent on the pasting surface of the vitrified tile. Table 2 lists the test results.

Embodiment 3

[0022] Repeat the method of Example 1 according to the content of each component specified in Example 3 in Table 1 below, but the interface agent is evenly brushed on the pasting surface of the vitrified tile by spraying, and the test results are listed in Table 2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap