Technology for coating inside woven bag by using polyether glycol composition

A polyether glycol, woven bag technology, applied in the direction of textile and paper making, single-component polyolefin artificial filament, spray/jet textile material treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

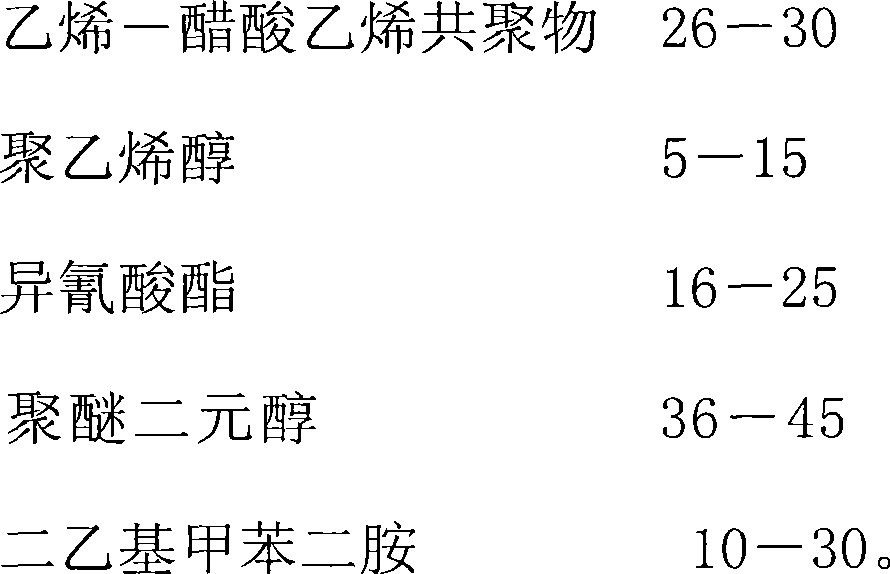

[0012] Add 0.4 part by weight of antioxidant 1010, 0.5 part by weight of ultraviolet absorber UV-327, 0.6 part by weight of auxiliary antioxidant DLTP according to 100 parts by weight of polypropylene resin; pass the obtained mixture through The extruder and the wire drawing machine are stretched and wound to make polypropylene filaments. On a circular loom, polypropylene filaments are used as warps and wefts to weave into a tubular fiber braided layer, and then a coating is sprayed on the inner side of the braided layer to form an inner lining, and the coating includes the following components (parts by mass) and content:

[0013]

[0014] After the above-mentioned coating components are prepared and mixed thoroughly on site, under the conditions of temperature of 45℃ and pressure of 10MPa, use a spray gun to spray on the inner side of the fiber braided layer to form an inner lining coating with a spray thickness of 0.1mm, and the inner surface is obtained after hot air dry...

Embodiment 2

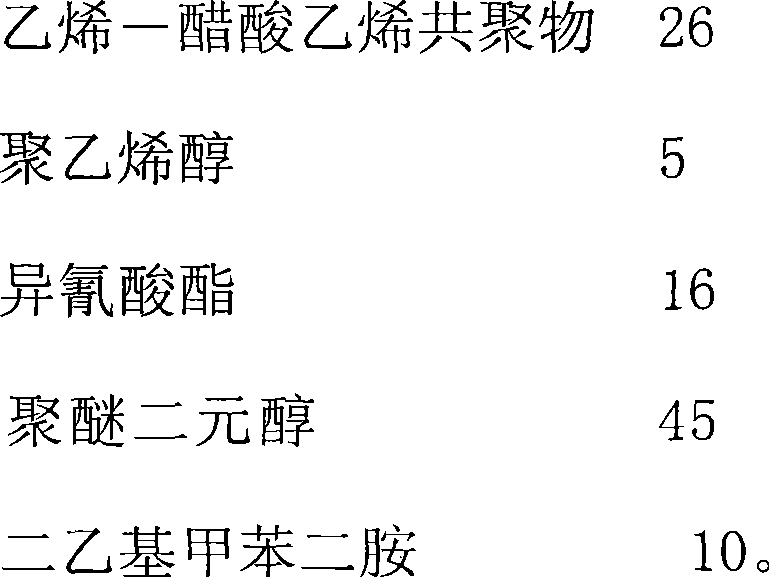

[0016] Repeating Example 1, the coating process of the woven bag is roughly the same as that in Example 1, except that the coating includes the following components (parts by mass) and content:

[0017]

[0018] The spraying temperature is 60℃, the spraying pressure is 15MPa, and the spraying thickness is 0.6mm.

Embodiment 3

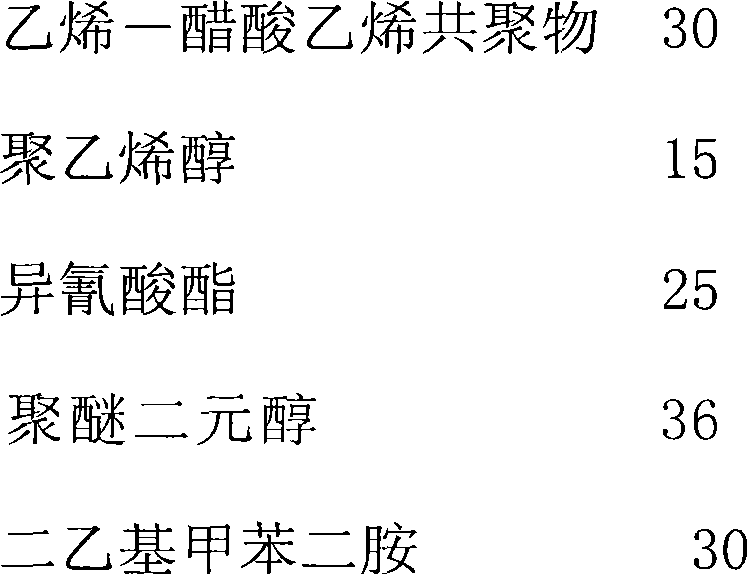

[0020] Repeating Example 1, the coating process of the woven bag is roughly the same as that in Example 1, except that the coating includes the following components (parts by mass) and content:

[0021]

[0022] The spraying temperature is 53℃, the spraying pressure is 13MPa, and the spraying thickness is 0.3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap