Aqueous acrylic resin which can degrade formaldehyde by using visible light and preparation method of aqueous acrylic resin

A water-based acrylic acid and methacrylic acid alkyl ester technology, applied in the direction of coating, can solve the problems of affecting the performance of the coating, harsh conditions, long time, etc., and achieve the effect of high viscosity, good film-forming performance, and removal of formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

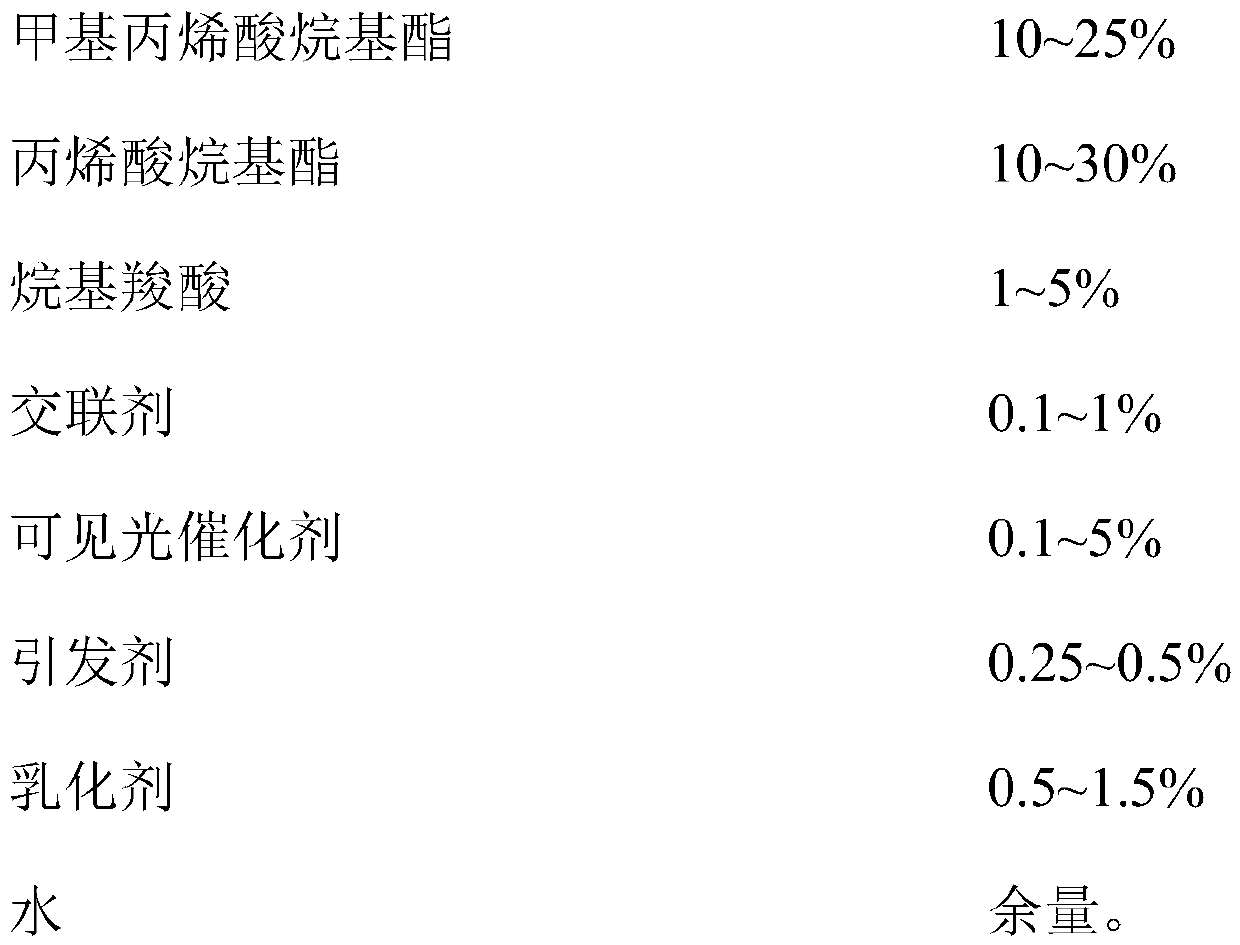

[0031] A water-based acrylic resin that degrades formaldehyde with visible light is made of methyl methacrylate, butyl acrylate, methacrylic acid, divinylbenzene and black phosphorus modified nano-titanium dioxide, and its specific component formula is as follows:

[0032]

[0033]

[0034] The preparation method of the water-based acrylic resin of the visible light degradation formaldehyde, its steps are as follows:

[0035] a. Preparation of black phosphorus modified nano-titanium dioxide; mixing the prepared nano-titanium dioxide and the stripped black phosphorus to make a visible light catalyst;

[0036]b. Take methyl methacrylate, butyl acrylate, methacrylic acid, divinylbenzene, and black phosphorus modified nano-titanium dioxide and mix them to make mixed monomers according to the above mass percentage ratio; The initiator and the emulsifier accounting for 41% of the total mass of the emulsifier were dissolved in deionized water accounting for 21% of the total mass o

Embodiment 2

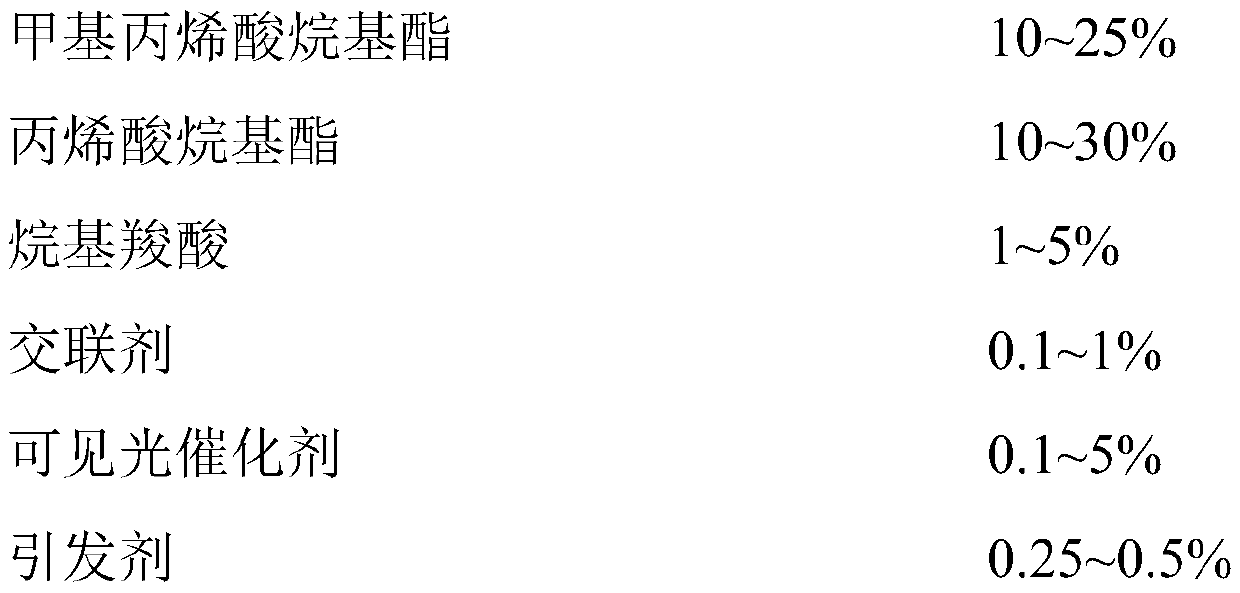

[0042] A water-based acrylic resin for visible light degradation of formaldehyde, made of methyl methacrylate, butyl acrylate, acrylic acid, divinylbenzene and black phosphorus modified nano-titanium dioxide, its specific component formula is as follows:

[0043]

[0044] The preparation method of the water-based acrylic resin of the visible light degradation formaldehyde, its steps are as follows:

[0045] a. Preparation of black phosphorus modified nano-titanium dioxide: the prepared nano-titanium dioxide and the exfoliated BP are mixed to make a visible light catalyst;

[0046] b. Weigh methyl methacrylate, butyl acrylate, acrylic acid, divinylbenzene, and black phosphorus modified nano-titanium dioxide according to the above mass percentage ratio to make mixed monomers; The emulsifier and the emulsifier accounting for 59% of the total mass of the emulsifier were dissolved in deionized water accounting for 39% of the total mass of water to prepare the first solution. Accor

Embodiment 3

[0052] A water-based acrylic resin for degrading formaldehyde by visible light, made of ethyl methacrylate, amyl acrylate, methacrylic acid, divinylbenzene and silicon dioxide-modified nano-titanium dioxide, and its specific component formula is as follows:

[0053]

[0054]

[0055] The preparation method of the water-based acrylic resin of the visible light degradation formaldehyde, its steps are as follows:

[0056] a. Preparation of silica-modified nano-titanium dioxide: mixing the prepared nano-titanium dioxide and nano-silicon dioxide to make a visible light catalyst;

[0057] b. Ethyl methacrylate, pentyl acrylate, methacrylic acid, divinylbenzene, and silica-modified nano-titanium dioxide are mixed to form a mixed monomer according to the above-mentioned mass percentage ratio; 45% of the initiator and 50% of the total mass of the emulsifier were dissolved in 30% of the total mass of deionized water to prepare a first solution. According to the FOX formula, the mixe

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap