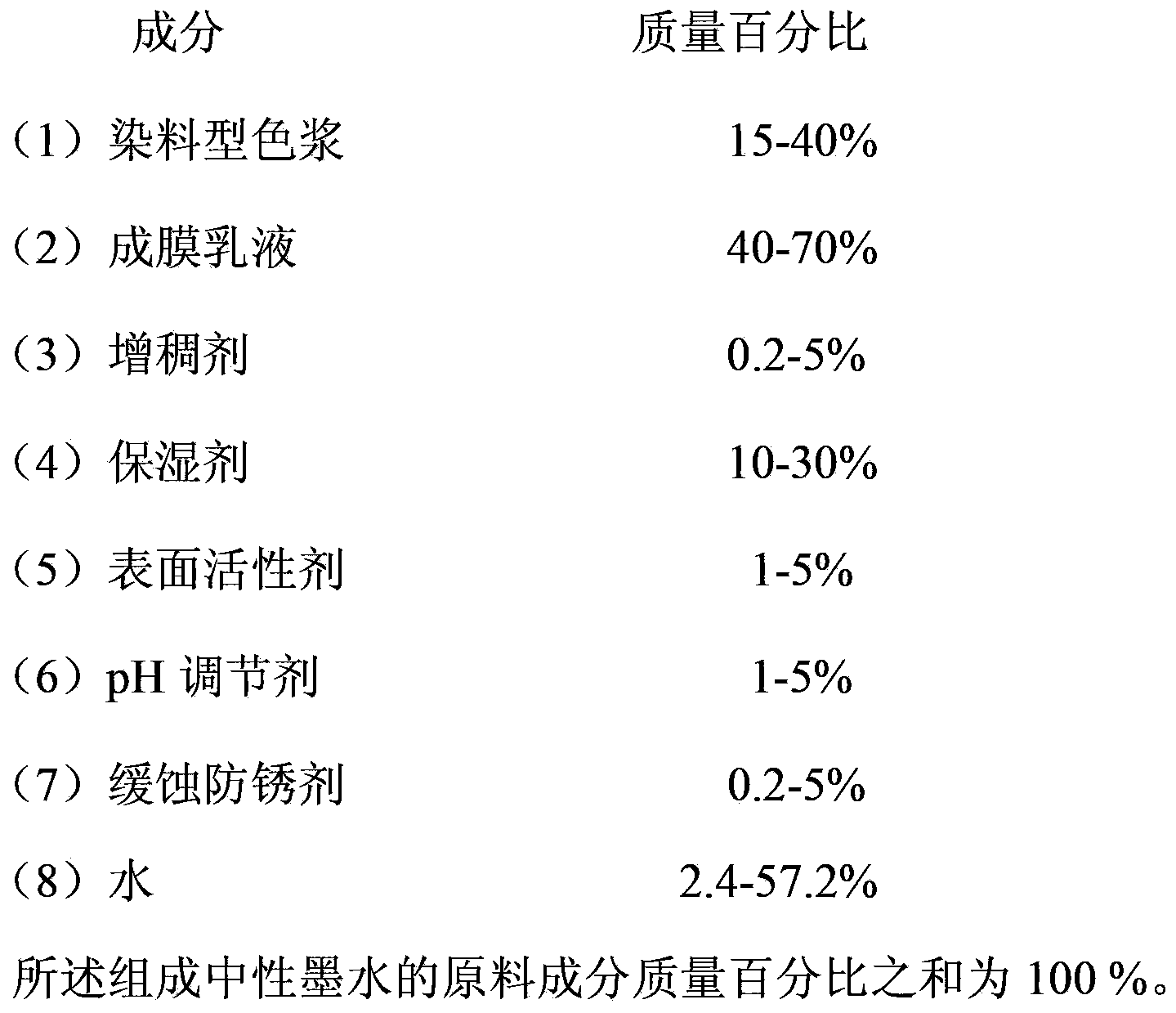

Dye-type neutral ink and preparation method thereof

A neutral ink and dye technology, used in inks, household appliances, applications, etc., can solve the problems of easy decolorization, poor water resistance, poor light fastness, etc., and achieve the effect of easy availability of raw materials, water resistance of handwriting, and good light fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Mix 10g glycerol, 1g surfactant OP-10, 1g triethanolamine, 0.3g benzotriazole, stir well, dissolve 0.5g xanthan gum in 57.2g water, mix well with the above mixture Stir, add 30g of ML14 dye paste, continue to stir and mix evenly, and defoam to obtain the finished product.

Embodiment 2

[0026] Mix 10g of glycerol, 1g of surfactant OP-10, 1g of triethanolamine, 0.3g of benzotriazole, and 43g of acrylic acid emulsion, stir well, dissolve 0.5g of xanthan gum in 14.2g of water, mix well with Mix and stir the above mixture, add 30g of ML14 dye paste, continue to stir and mix evenly, defoam and obtain the finished product.

Embodiment 3

[0028] Mix 10g of glycerol, 1g of surfactant OP-10, 1g of triethanolamine, 0.3g of benzotriazole, and 43g of acrylic acid emulsion, stir well, dissolve 0.5g of thickener xanthan gum in 14.2g of water, and stir After it is fully mixed with the above mixture, add 30g of pigment paste, continue to stir and mix evenly, and defoam to obtain the finished product.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap