Dispersions containing alkoxylates of alicyclic polycyclic compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0106]The reaction is carried out in a Parr Pressure reactor as follows: To 1 mole equivalent of Cyclecanol, 0.1% KOH is added. The mixture is purged with N2 and then the vessel is evacuated and vacuum stripped for 30 minutes at 105° C. The vessel is brought to 0 psi with N2 and then EO is introduced slowly to initiate the reaction. After initiation, the EO is fed at 140° C. until 70 equiv wts of EO have been added. The product is vacuum stripped and neutralized with acetic acid prior to discharge from the reactor.

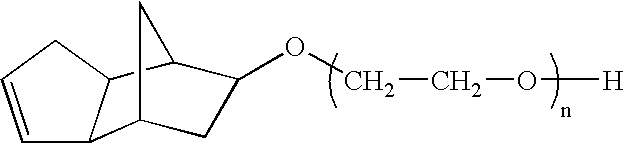

[0107]The structure of the resulting compound of example 1 is:

wherein n=70.

example 2

[0108]The following components are reacted using the procedure of Example 1.

COMPONENTAMOUNTTerpineolone mole equivalentKOH0.1%Ethylene oxideuntil 70 equivalents have been added

[0109]The resulting product is a pale liquid.

example 3

[0110]The following components are reacted using the procedure of Example 1.

COMPONENTAMOUNTAdamantanolone mole equivalentKOH0.1%Ethylene oxideuntil 70 equivalents have been added

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap